Patents

Literature

99results about How to "Reduce beany smell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of high-salt diluted and low-temperature fragrant soy sauce

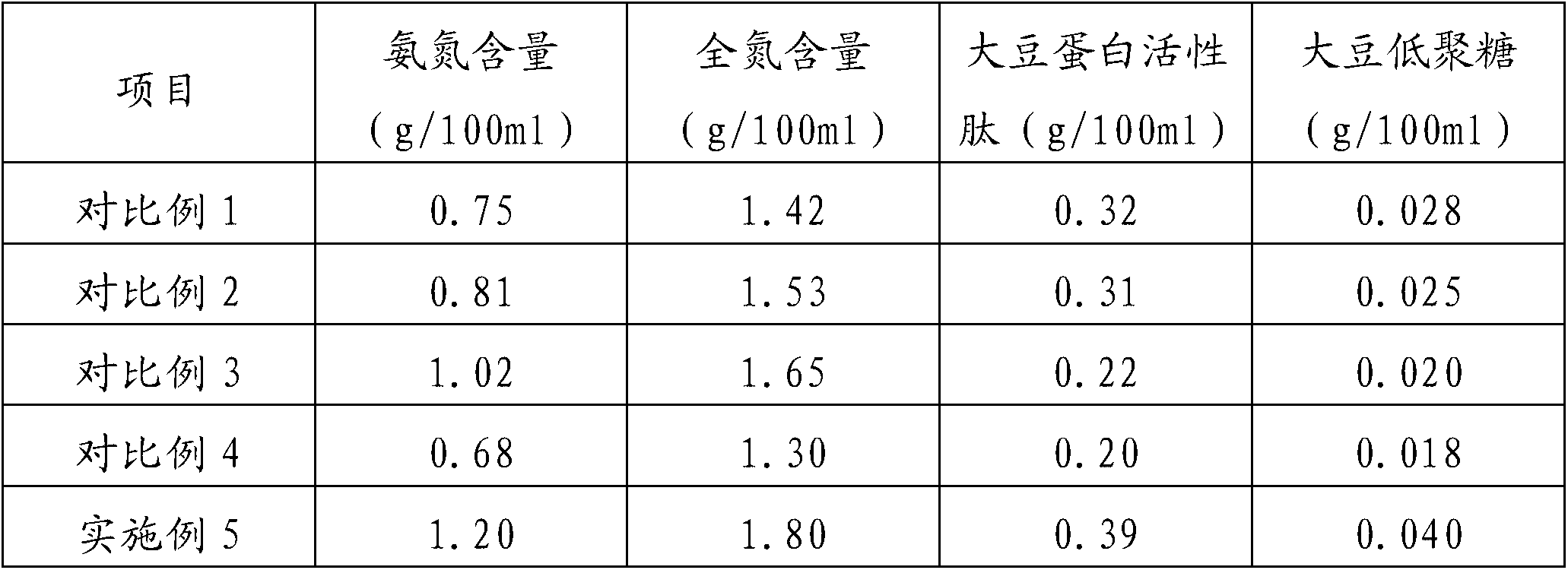

The invention discloses a production method of a high-salt diluted and low-temperature fragrant soy sauce, which comprises the following steps of: (1) curing raw materials including wheat and defatted soybeans, and then uniformly mixing the wheat and the defatted soybeans; (2) inoculating aspergillus oryzae strains to the obtained raw material mixture so as to obtain a yeast; (3) cultivating the yeast for 44-48 hours at a temperature of 25-30 DEG C so as to obtain a mature yeast; (4) adding 2.0-2.5 weight times of saline water into the mature yeast so as to obtain a raw soy sauce mash; (5) moving the raw soy sauce mash to the inside of an airtight fermentation tank for fermenting: firstly fermenting for 23-27 days at a temperature of 13-17 DEG C, then continuing to ferment at a temperature of 28-32 DEG C, and on the 28-32nd days, adding mixed fermentation strains into the fermentation tank and continuing to ferment; in the process of fermentation, stirring by using a compressed air flow; and fermenting for more than six months so as to obtain a mature soy sauce mash; and (6) squeezing and filtering the mature soy sauce mash so as to obtain the low-temperature fragrant soy sauce. According to the invention, the conversion rate of proteins in raw materials is high, and the contents of ammonia nitrogen, total nitrogen, soybean peptides and soybean oligosaccharides in the prepared soy sauce are high.

Owner:好太太食品有限公司

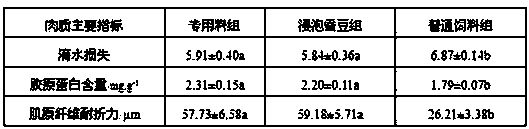

Special formula feed for improving tilapia mossambica meat quality and preparation method thereof

InactiveCN103380861AImprove meat qualityFirm and crispy meatClimate change adaptationAnimal feeding stuffBiotechnologyAnimal science

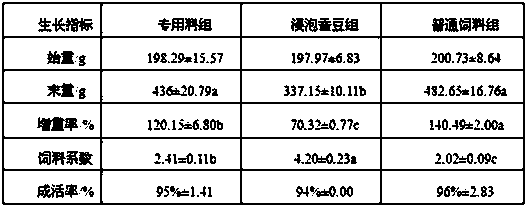

The invention relates to the field of aquatic feed, in particular to special formula feed for improving tilapia mossambica meat quality and a preparation method thereof. Ingredients in a feed formula comprise, by weight, 40-70 parts of broad bean, 2-5 parts of fish meal, 7-12 parts of bran, 9-19 parts of rapeseed dregs, 8-19 parts of peanut meal, 1-2 parts of fish oil, 0.3-0.5 part of glycine betaine, 0.4-0.6 part of choline chloride, 0.6-0.8 part of monocalcium phosphate, 0.10-0.13 part of methionine, 0.06-0.1 part of enzyme preparation, 0.02-0.03 part of allicin, 0.4-0.6 part of multivitamins and 1.0-1.2 parts of complex mineral. The preparation method of the feed is further provided. The feed can improve the tilapia mossambica meat quality to be firm, hard, crisp and tasty, improves growth performance of tilapia mossambica, reduces pollution on water quality and production cost and remarkably improves economical and social benefit.

Owner:福建省淡水水产研究所

Double protein pudding and its preparation method

ActiveCN103907834ADelicate tissue stateRich varietyFood ingredientsFood preparationProtein contentAnimal proteins

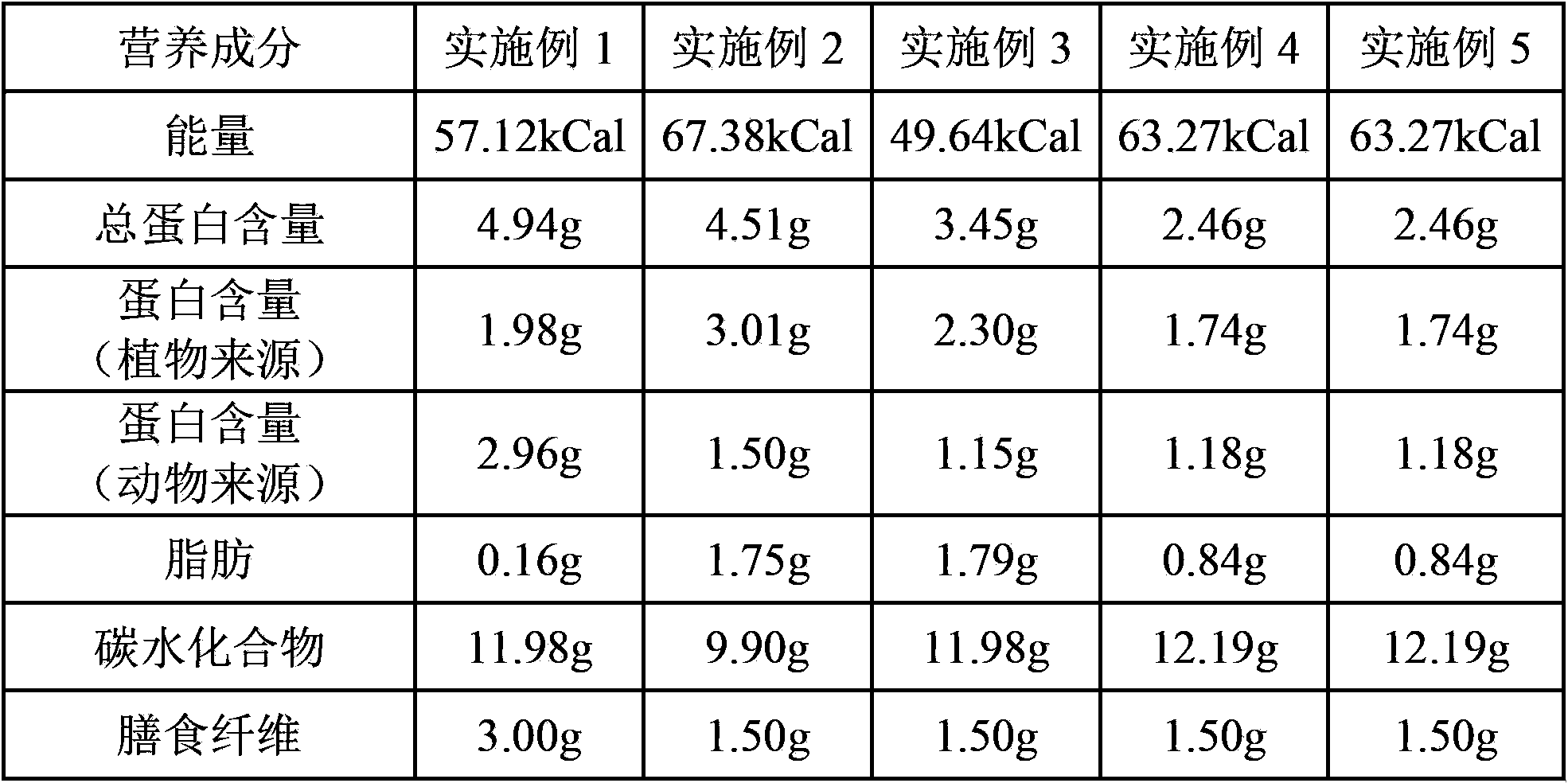

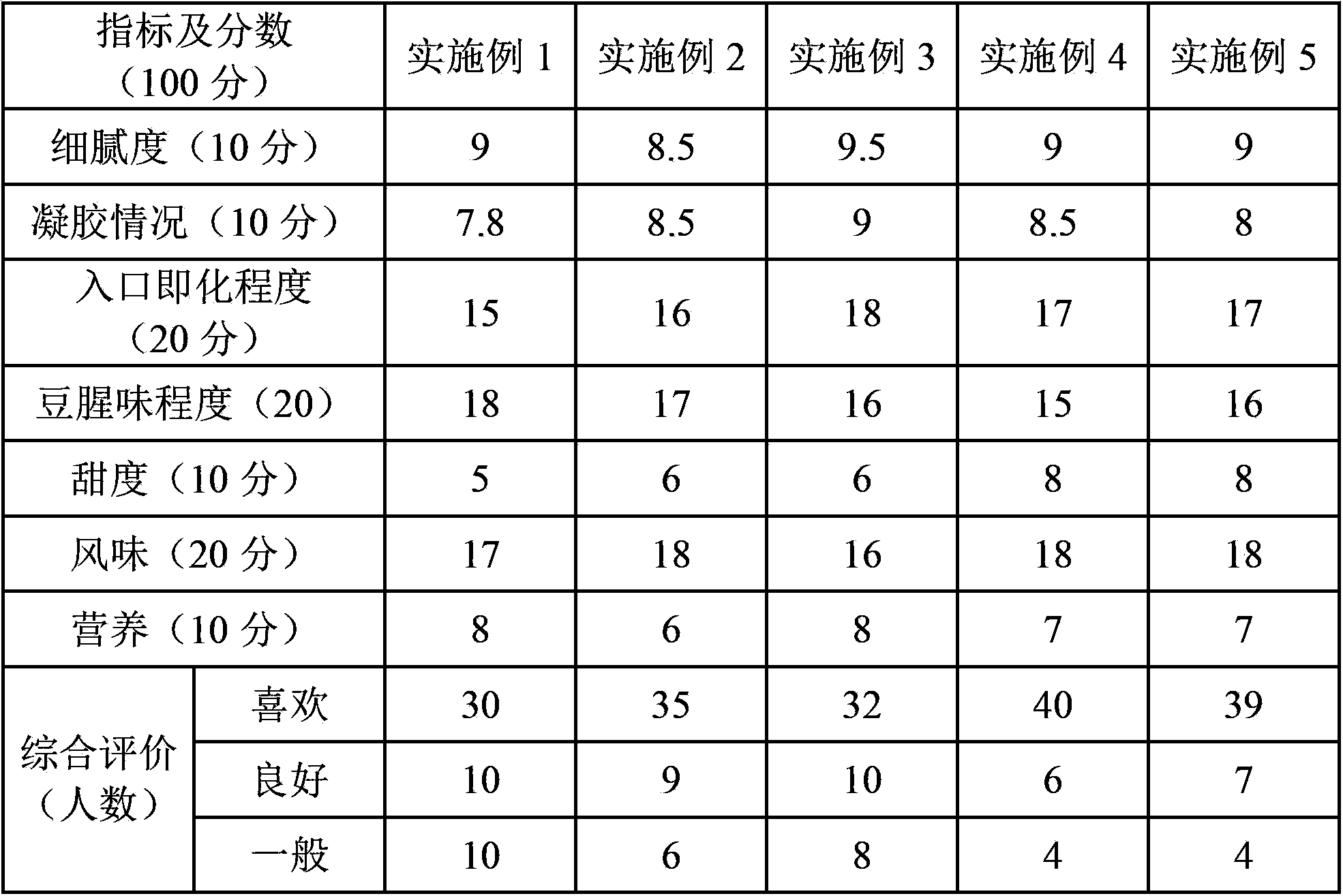

The invention provides a double protein pudding product, which comprises the following components by mass part: 2-5 parts of soybean protein, 3-8 parts of milk powder, 4-8 parts of sweetener, 0.4-0.8 parts of modified starch, 0.1-0.6 parts of food gum and 80-85 parts of water. According to the double protein pudding product, vegetable protein and animal protein are combined, the protein content is high, the tissue state is finer, and the double protein pudding product is a nutrition and health product. The double protein pudding product has reasonable distribution ratio, so that the pudding product has a semi-solidification type state, and has soft and fine mouthfeel, and just melts in the mouth, the double protein pudding product is different with the gel feeling of a traditional pudding product, and provides different desert experience to the consumer.

Owner:COFCO NUTRITION & HEALTH RES INST +1

Special compound feed for tilapia meat quality improvement and preparation method thereof

InactiveCN103960529AImprove meat qualityFirm and crispy meatClimate change adaptationAnimal feeding stuffBiotechnologyAnimal science

The invention relates to the field of aquatic feed and particularly provides special compound feed for tilapia meat quality improvement and a preparation method thereof. The feed comprises the following components in parts by weight: 40-70 parts of broad bean, 2-5 parts of fish meal, 7-12 parts of bran, 9-19 parts of rapeseed mea1, 8-19 parts of peanut meal, 1-2 parts of fish oil, 0.3-0.5 part of glycine betaine, 0.4-0.6 part of choline chloride, 0.6-0.8 part of monocalcium phosphate, 0.10-0.13 part of methionine, 0.06-0.1 part of enzyme preparation, 0.02-0.03 percent of garlicin, 0.4-0.6 percent of compound vitamin and 1.0-1.2 parts of composite mineral salt. The invention also provides a preparation method of the feed. The feed has the benefits that the tilapia meat quality can be improved, so that tilapia meat is hard and crisp; and the growth performance of tilapia is improved, so that the pollution to the water quality is reduced, and the production cost is reduced, therefore, the economic and social benefits are remarkable.

Owner:福建省淡水水产研究所

Method for improving flavor of bacillus natto fermented whole-soybean milk

InactiveCN105145852AAdd flavorGuaranteed functional factorMilk substitutesFood scienceLactobacillusSoybean product

The invention discloses a method for improving the flavor of bacillus natto fermented whole-soybean milk, and belongs to the technical field of fermented soybean product processing. With soybeans being raw materials, whole-soybean milk is prepared through the technology of selecting, soaking, hot water heating, coarse smashing, ultrafine smashing and high-pressure homogenizing, bacillus natto and lactic acid bacteria are separately inoculated into the sterilized and cooled whole-soybean milk to be fermented, then bacillus natto fermented soybean milk and lactic acid bacterium fermented soybean milk are mixed and blended according to a proportion, and then the whole-soybean milk is obtained. While the taste is guaranteed, the soybeans are fully utilized, in this way, pollution to the environment is avoided, and the capacity, for generating acid and aroma in the soybean milk, of lactic acid bacteria is utilized for effectively improving the flavor of the fermented soybean milk. Meanwhile, the liquid fermentation technology that bacillus natto and lactic acid bacteria are separately fermented and then blended is adopted, pipeline transportation can be achieved, control over fermentation conditions and a fermentation end point is easier, the range is easy to enlarge, the components are easy to control, and follow-up processing is simple.

Owner:JIANGNAN UNIV

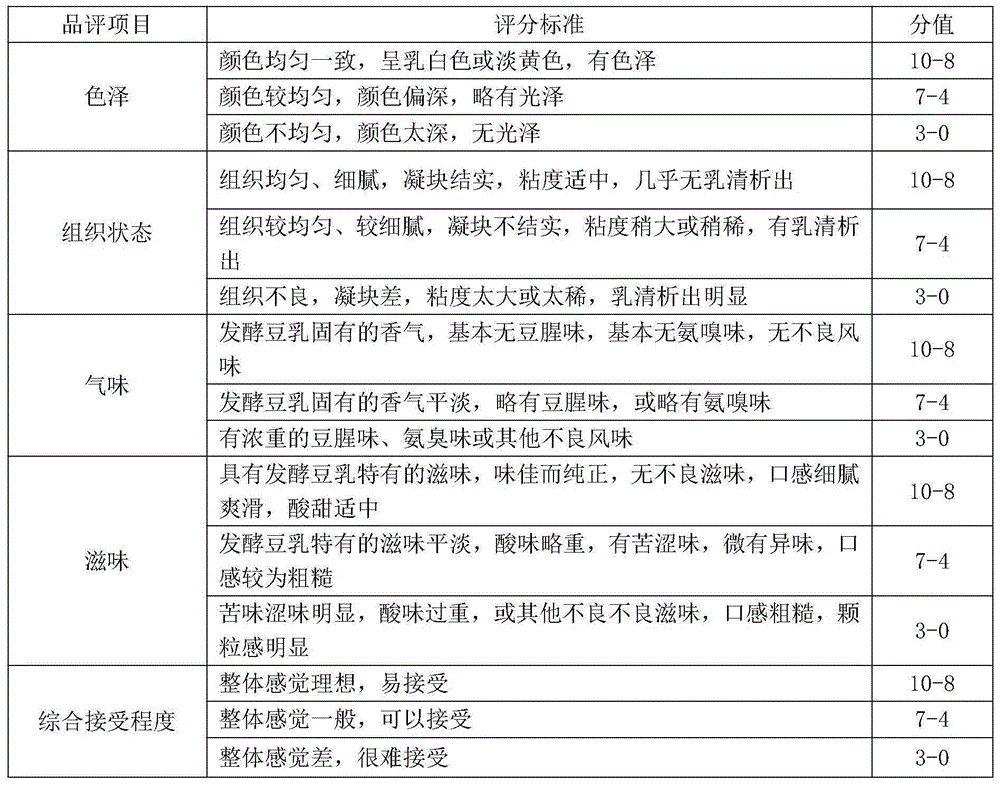

Soybean milk and dry-process preparation method thereof

InactiveCN104814156AReduce the residue of soil bacteriaRemove beany smellMilk substitutesFood scienceProcess engineeringSoy milk

The invention discloses soybean milk. The soybean milk comprises the following components in parts by weight: 60-68 parts of soybeans, 50-65 parts of white sugar, 850-875 parts of water, 2-4 parts of a soybean-milk stabilizing agent and 0.8-1.5 parts of other auxiliary materials, wherein the pH is 7.0-7.3. A dry-process preparation method for the soybean milk comprises the following steps: (1) adopting a baking dry process for enzyme deactivation and peeling, namely sieving the soybeans to remove impurities, putting into a baking oven, baking for 10-18 minutes under the temperature of 100-110 DEG C, taking out the soybeans when the soybeans have the 40%-50% cooking degree, cooling and peeling; (2) grinding into soybean milk, namely carrying out coarse crushing on the peeled soybeans in the step (1) till irregular particles with the particle diameter being 2-3mm appear, then adding water with the weight being 2-2.5 times of the weight of the soybeans, and grinding the soybeans in the form of irregular particles into the soybean milk; (3) adding the auxiliary materials for mixing the soybean milk: (4) blending; (5) adjusting the pH, and adding water to obtain the constant volume; (6) homogenizing and sterilizing; and (7) carrying out canning and secondary sterilization. The dry-process preparation method has the advantages that the production period is short, the cost is low and the production operation is easy.

Owner:湖南湘鹰食品科技有限公司

Composition capable of adjusting blood pressure, reducing blood sugar and complementing nutrition

The invention provides a composition capable of adjusting blood pressure, reducing blood sugar and complementing nutrition, which can complement nutrient substances and enhance the functions of human bodies. The composition is characterized by being prepared from the following components in parts by mass: 20-30 parts of corn oligopeptide, 20-30 parts of wheat oligopeptide, 10-15 parts of soybean oligopeptide, 5-10 parts of fructose, 3-10 parts of apigenin, 3-10 parts of maltodextrin, 1-10 parts of vitamins and 5-15 parts of microcrystalline cellulose.

Owner:吉安市御美丽健康产业股份有限公司

Fruit juice soymilk beverage and production method thereof

The invention discloses a fruit juice soymilk beverage and a production method thereof, which is characterized in that acidulous fruit juice, such as soy bean, condensed honey-dew melon juice, condensed leechee juice or condensed papaya juice and the like, serves as a raw material; sweetener, acidity regulation and emulsion stabilizer serve as auxiliary materials; and the raw material and the auxiliary materials are mixed, homogenized, sterilized and filled to prepare a honey-dew melon juice soymilk beverage. The honey-dew melon juice soymilk beverage of the invention combines the nutritional value of fruit juice and soymilk and has clear taste and pleasant sweetness and sourness; and meanwhile, the honey-dew melon juice soymilk beverage has stable quality, the shelf life is more than 9 months, and the processing technology route is suitable for industrialized mass production.

Owner:JIANGNAN UNIV

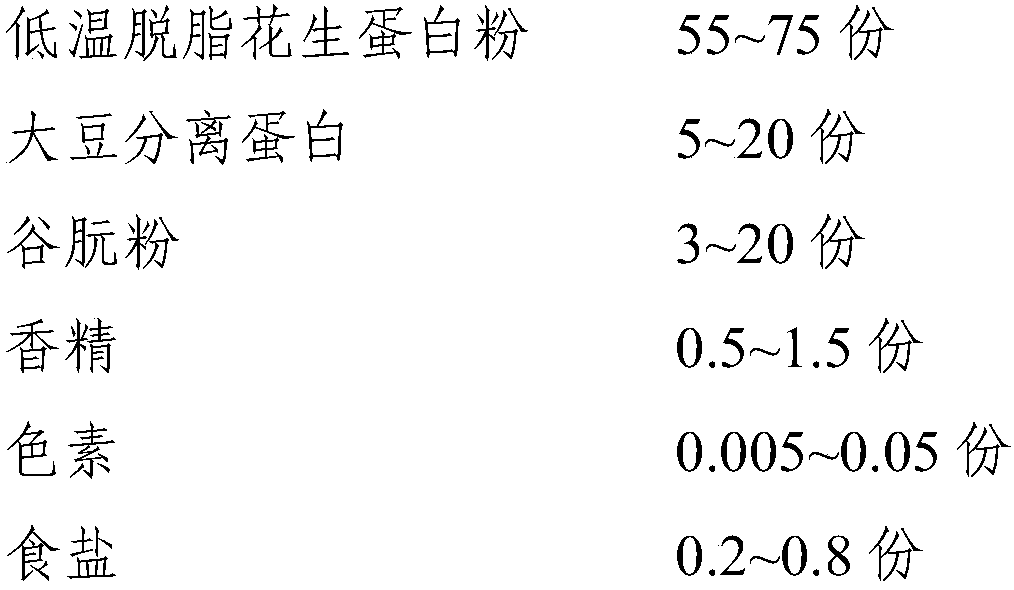

Peanut protein vegetarian sausage and preparation method thereof

PendingCN108095128AFull of nutritionReduce beany smellProteins working-up by texturisingFood ingredient as taste affecting agentCholesterolWater content

The invention relates to a peanut protein vegetarian sausage and a preparation method thereof. The peanut protein vegetarian sausage is prepared from the following raw materials by weight: 50-100 parts of low temperature defatted peanut protein powder, 5-50 parts of soy protein isolate, 5-50 parts of wheat gluten, and 0.1-10 parts of a modifier. The vegetarian sausage has a protein content of 60%or more, zero cholesterol and low fat, and has the characteristics of good taste, rich nutrition, convenient eating and the like. The invention also discloses a preparation method of the vegetarian sausage. The method specifically includes: fully mixing the main materials, then conducting extrusion treatment at 100-200DEG C, adding water and auxiliary materials on line during extrusion, conductingextrusion molding and then performing cooling, thus obtaining the product. Specifically, with the added water amount, the water content of the materials during extrusion can reach 45%-75%. The preparation method is a pure physical processing method, has a high degree of automation and is free of pollutant emission during processing.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI +1

Mung bean and soy bean milk and method for preparing same

InactiveCN101700075AImprove water absorptionReduce dosageMilk substitutesFood scienceAdditive ingredientFood flavor

The invention discloses mung bean and soy bean milk and a method for preparing same. The method for preparing the mung bean and soy bean milk comprises the following steps: boiling the mung beans in boiling water for 1-5min; soaking the boiled mung beans in water with the temperature of not higher than 40 DEG C for 4-8h, wherein the proportion of the mung beans to the water is 1:3-7; soaking soy beans in water with the temperature of not higher than 40 DEG C for 4-8h, wherein the proportion of the soy beans to the water is 1:3-7; mixing the soaked mung beans and the soaked soy beans; adding water with the temperature of 80-100 DEG C to grind the soaked mung beans and the soaked soy beans; filtering to obtain the raw mung bean and soy bean milk; adding xanthan gum to the raw mung bean and soy bean milk, wherein the mass of the xanthan gum is 0.05-0.1 percent of the mass of the raw mung bean and soy bean milk; and homogenizing and sterilizing the raw mung bean and soy bean milk at high pressure to obtain the mung bean and soy bean milk. The method for preparing the mung bean and soy bean milk is easy, optimizes all the parameters, saves water and time and has low cost, and the mung bean and soy bean milk prepared with the method has good taste, flavor and color, abundant nutrients and long shelf life, therefore, the method for preparing the mung bean and soy bean milk is suitable for the industrial production.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of soybean protein health-care beverage

InactiveCN103404596AReduce beany smellSolve indigestionFood preparationMilk substitutesFiltrationDiarrhea

The invention relates to a food processing method and especially relates to a preparation method of a soybean protein health-care beverage. The preparation method comprises the following steps of immersing soybean, carrying out grinding to obtain soybean paste, adding barley malt powder into the soybean paste, carrying out fishy smell elimination, carrying out filtration to obtain soybean mild having no soybean odor, and carrying out blending, homogenization, bottling and sterilization on the soybean mild having no soybean odor. The soybean paste is added with the barley malt powder and through rich enzymes such as aldehyde dehydrogenase in barley malt, soybean substances having soybean odor are decomposed so that soybean odor of the soybean protein health-care beverage is effectively reduced. Through the protease of barley malt, the most of the soybean proteins are decomposed so that soybean protein beverage-caused dyspepsia is prevented and soybean protein beverage-caused abdominal distension and diarrhea are avoided.

Owner:HARBIN WEIPING TECH DEV

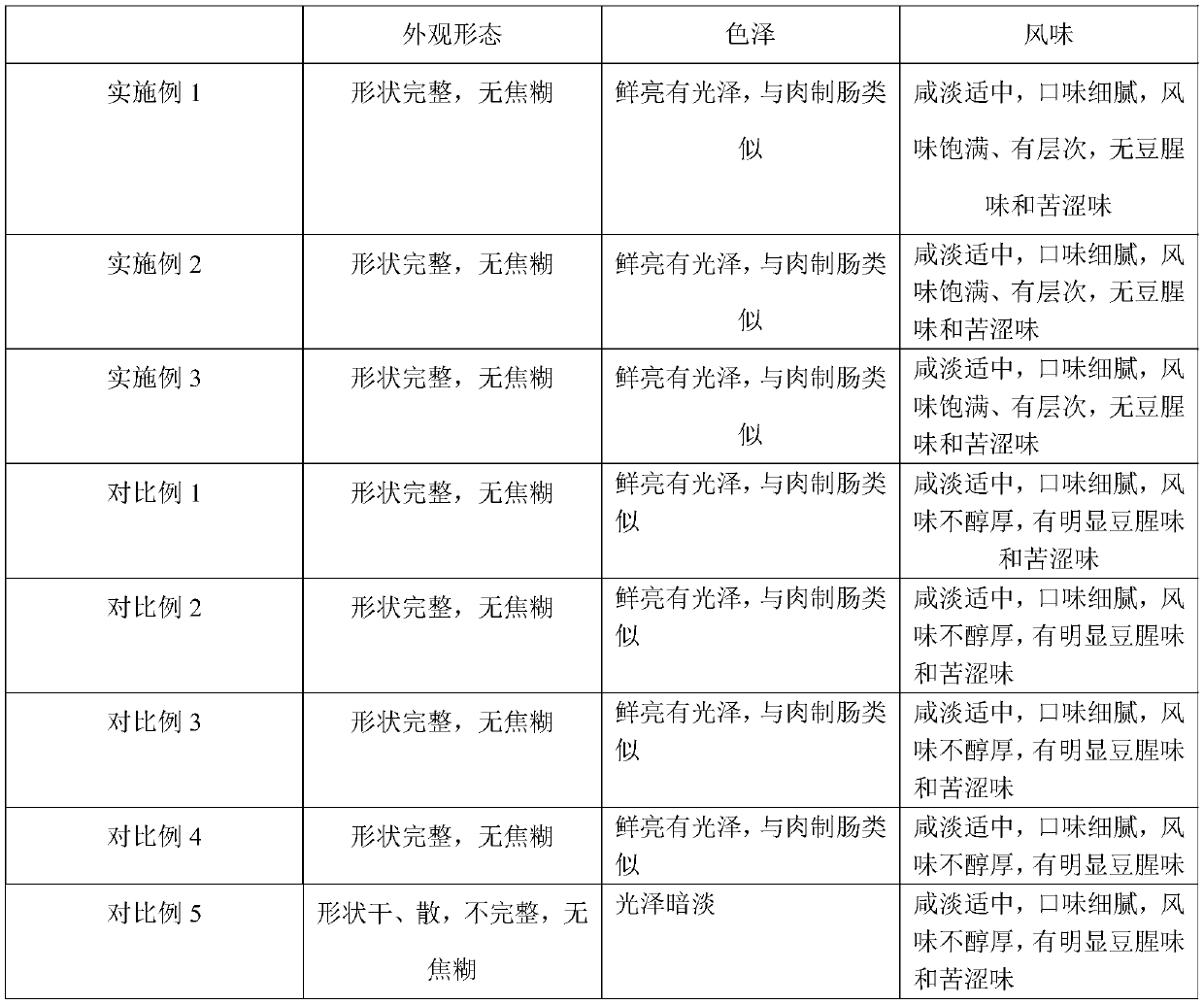

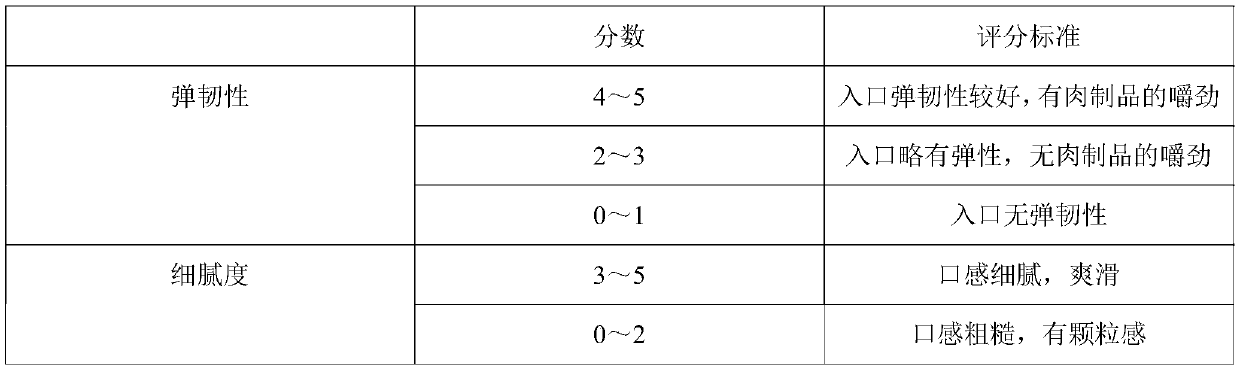

Vegetable protein sausages capable of effectively reducing beany flavor and bitter flavor, and preparation method of vegetable protein sausages capable of effectively reducing beany flavor and bitter flavor

PendingCN111202234AReduce beany smellReduce bitternessFood ingredient as thickening agentFood ingredient as taste affecting agentBiotechnologyVegetable oil

The invention discloses vegetable protein sausages capable of effectively reducing beany flavor and bitter flavor, and a preparation method of the vegetable protein sausages capable of effectively reducing beany flavor and bitter flavor. Plant isolated protein and plant wire drawing protein are used as basic raw materials, vegetable oil, edible salt, natural pigment, a compounding enzyme preparation, a compounding thickening agent, compounding spice, a compounding sweetening agent, a compounding sweetening agent, edible essence, modified starch and the like are used as auxiliary materials, andthrough steps of performing beany flavor elimination and bitter flavor elimination treatment, performing marinating, performing preserving, chopping and mincing, performing stirring, performing stuffing, performing sterilization and the like, the vegetable protein sausages are obtained. The beany flavor and the bitter flavor can be effectively reduced, and mouth feel, flavor and color of the vegetable protein sausages are similar to those of traditional meat sausages; besides, the vegetable protein sausages does not contain animal raw materials; and through high-temperature sterilization, thevegetable protein sausages can be preserved at normal temperature for 6 months.

Owner:临沂金锣文瑞食品有限公司

Pawpaw peptide liquor and making method thereof

ActiveCN105039089ANo beany smellImprove palatabilityAlcoholic beverage preparationFood flavorLemon juice

The invention relates to pawpaw peptide liquor and a making method thereof. The pawpaw peptide liquor mainly comprises, by weight, 80-100 parts of pawpaw juice, 20-50 parts of water, 20-25 parts of bean pulp, 15-20 parts of lemon juice, 10-20 parts of white granulated sugar and 0.1-0.5 part of spices. The making method of the pawpaw peptide liquor mainly includes the steps of mixing, spice extract preparation, enzymolysis, primary fermentation, post fermentation, filtering, clarification, filling, sterilization and the like. The pawpaw peptide liquor and the making method thereof have the advantages that the utilization rate of the raw materials is high and sulfur dioxide does not need to be added in the production process; besides, the made pawpaw peptide liquor is strong in flavor, good in nutrition, free of the beany flavor and good in palatability, and the pawpaw peptide liquor has certain functions of feature beautifying, skin nourishing, immunity improving and the like.

Owner:南宁荣港生物科技有限公司

Preparation method for peptide-containing whole bean powder, and soya-bean milk, thick soy milk and bean powder prepared by the same

InactiveCN110089574AThe process steps are simpleReduce manufacturing costMilk substitutesFood sciencePeptideChemistry

The invention relates to a preparation method for peptide-containing whole bean powder, and soya-bean milk, thick soy milk and bean powder prepared by the same. The preparation method includes the following steps: performing pretreatment on a soybean raw material, and performing hot refining; performing enzyme hydrolysis, performing protease hydrolysis or complex enzyme hydrolysis on soya-bean milk prepared by the step two, wherein the soya-bean milk can generate soybean peptide after enzyme hydrolysis so that peptide-containing soya-bean milk can be prepared; and adding one or more combinations of seasoning, food ingredients and functional ingredients into the peptide-containing soya-bean milk after the enzyme hydrolysis so that the peptide-containing soya-bean milk with compound tastes can be prepared. Thus, simple process steps and low production costs can be achieved, and bean dregs cannot be discharged, so that the full utilization of soybean fiber can be realized, and the full utilization of whole bean resources can be achieved; and pollution to environmental protection can be avoided, and therefore, traditional bean product industries can be enhanced.

Owner:夏建伟

Automatic processing technology for stand-up pouch soymilk

ActiveCN103988915AReduce beany smellGuaranteed qualityMilk substitutesFood scienceCentrifugationProcess engineering

The invention discloses an automatic processing technology for stand-up pouch soymilk. The automatic processing technology comprises the following main steps: material selection; soaking; enzyme killing; pulp refining; centrifugation; continuous pulp cooking; filtering; blending; homogenization; primary sterilization; filling; secondary sterilization; and cooling. The automatic processing technology has the characteristics of safety, health, high efficiency, conservation of energy, environmental protection, low processing cost, etc.; the prepared soymilk is safe, nutritious and healthy, tastes good and has quality far better than the quality of soymilk products produced by using traditional processing technology.

Owner:安吉祖名豆制食品有限公司

Flour quality modifying agent preparation taking bean dregs as principal raw material

InactiveCN101253960AReduce beany smellNot easy to recolorDough treatmentFood preparationFiberAdditive ingredient

The invention relates to a method for producing flour improver with bean dregs as the main ingredient, and relates to the comprehensive utilization field of farm and sideline products. The method comprises the steps of deodoring, decoloring, dehydrating, and super-finely pulverizing the main ingredient of moist bean dregs to obtain bean dregs fiber flour, namely the flour improver. The method is simple, has low production cost, and can utilize the key components in the bean dregs and increase the content of soluble polysaccharide. The flour improver can be added to various kinds of flour, and has significant flour improving effect.

Owner:山东创新源农业技术开发有限公司

Fermented bean dreg paste

The invention mainly relates to the technical field of foods, and discloses fermented bean dreg paste. The fermented bean dreg paste is made from the following raw materials of bean dregs, brine, peanuts, millet, carrots, bacillus natto, lactic acid bacteria and a garlic extract. The fermented bean dreg paste is rich in raw materials, balanced in nutrients, rich in fresh and fragrant taste, moderate in stickness, acid, hot and palatable; bean dregs are turned into wealth from waste, so that the fermented bean dreg paste is low in price, and the economic returns are increased by 21.4%; the bean dregs are collected, then freeze drying is performed on the collected bean dregs, moisture in the bean dregs is removed, beany flavor is reduced, besides, the absorption of brine by the bean dregs can be increased, and product fragrance can be improved; millet is fried to generate fragrance, water is added, and then cooking is performed, so that the starch dextrinization of the millet is accelerated, digestion and absorption are promoted, and the fragrance and the viscosity of rice porridge are increased; and after dried bean dregs are added to the brine and the peanut powder, the bacillus natto is inoculated, and fermentation is performed, so that nutrient components in the bean dregs are fully utilized, natto kinase is produced, palatable taste is increased, the beany flavor is reduced, the digestion and the absorption are promoted, and heart and cerebral vessels are protected.

Owner:蚌埠市星光豆制品厂

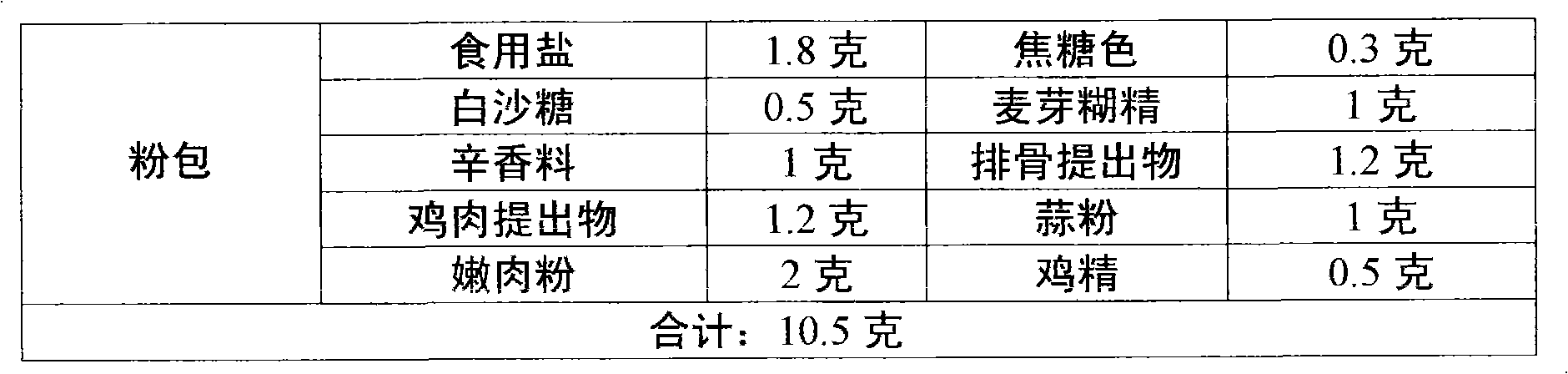

Beancurd skin instant noodles and manufacturing method thereof

The invention discloses beancurd skin instant noodles, which comprises beancurd skin and is characterized in that the beancurd is prepared from the raw materials of rice, peas, flour and edible salt. A manufacturing method for preparing the beancurd skin instant noodles and the manufactured beancurd skin instant noodles thereby have less beany flavor and good taste due to adopting unique raw materials to prepare the beancurd skin, the nutrition collocation is more reasonable, and additives like legumin activity antistaling agent can be reduced even stopped using, thus the beancurd skin instant noodles in the invention conforms to the requirements of healthy food better.

Owner:邹德泽

Spicy composite bean dreg sauce and processing method thereof

The invention provides spicy composite bean dreg sauce and processing method thereof. The spicy composite bean dreg sauce comprises the following components in parts by weight: 54-56 parts of edible vegetable oil, 28-30 parts of fermented bean dregs, 5.2-6.4 parts of chilli powder, 1.8-2.2 parts of soybean paste, 1.6-1.8 parts of thick broad-bean sauce, 1.8-2.2 parts of edible salt, 1.3-1.5 parts of cooked sesame kernels, 1.0-1.2 parts of bruised ginger, 0.8-1.0 part of trehalose, 0.6-1.0 part of chicken essence seasoning, 0.4-0.6 part of white granulated sugar, 0.2-0.4 part of five spice powder and 0.2-0.4 part of seed powder of Chinese prickly ash. The processing method mainly comprises the following steps: processing of the fermented bean dregs, stir-frying, filling and sterilizing. The spicy composite bean dreg sauce is nutrient-rich, tastes fine and smooth, is delicious, and is outstanding in flavor, attractive in color and long in expiration date.

Owner:黑龙江棒星食品科技股份有限公司

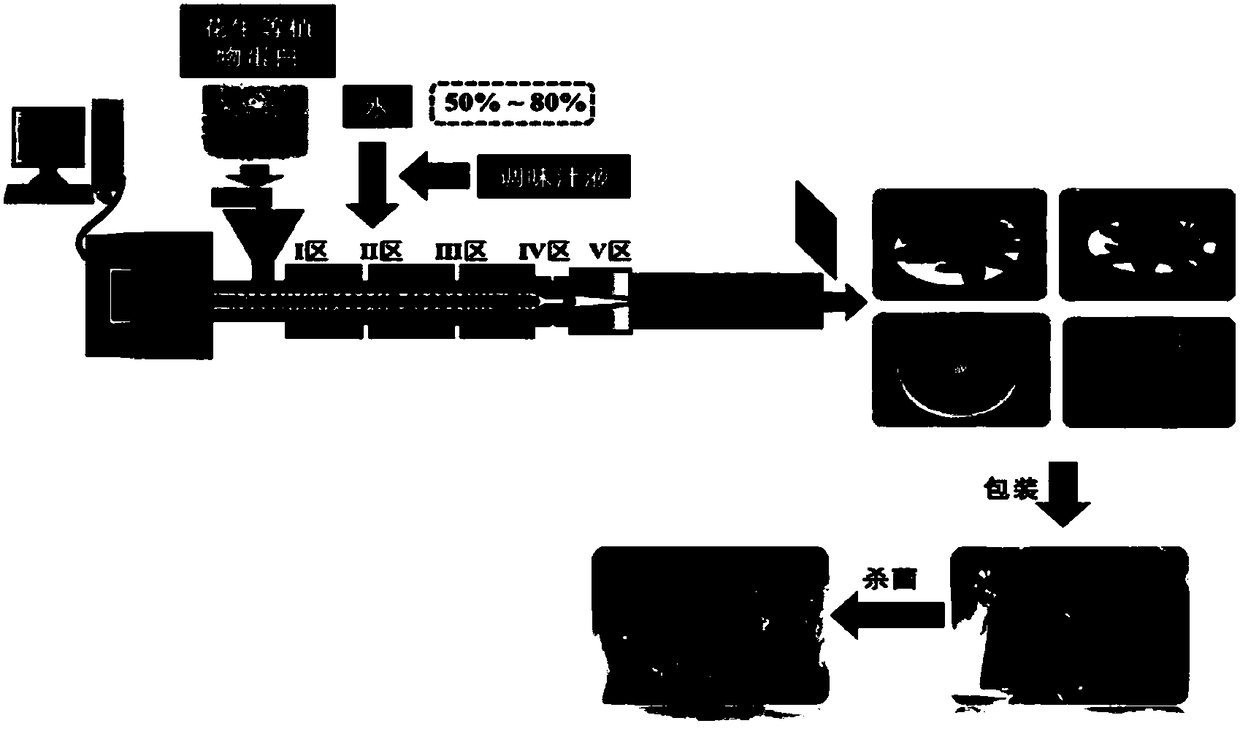

Production method for preparing high-moisture low-allergen vegetable meat from rice protein

PendingCN111955596AReduce surface temperatureReduce water lossProteins working-up by texturisingVegetable proteins working-upChemistryTissue protein

The invention discloses a production method for preparing high-moisture low-allergen vegetable meat from rice protein. The production method comprises the following steps of selecting raw materials ofthe rice protein, pea protein and rice starch; adding the raw materials of the rice protein, the pea protein and the rice starch into a sealed powder stirring tank, and performing stirring and mixingto obtain a mixture; injecting water into the powder stirring tank, controlling the moisture of the mixture to be 10-40%, and performing stirring for 5-20 minutes; in a double-screw extruder and cooling extrusion equipment, supplementing the moisture of the mixture to be 60-80%; and performing atomization spraying after material extrusion forming, then cutting the materials into protein blocks, and performing vacuum packaging on the protein blocks. High-moisture tissue protein prepared from the pea protein and the rice protein as the main raw materials has the better elasticity, chewiness andmeat texture in comparison with traditional dry process tissue protein, does not need to be rehydrated, and can be directly used as the plant meat raw material.

Owner:ANHUI SHUNXIN SHENGYUAN BIOLOGICAL FOOD CO LTD

Soybean vegetarian meat raw material containing seaweed dietary fibers, product and preparation method of product

PendingCN112205579AReduce beany smellOrderly rowsCheese manufactureFood shapingBiotechnologyDietary fiber

The invention discloses a soybean vegetarian meat raw material containing seaweed dietary fibers. The soybean vegetarian meat raw material comprises 70-90 parts of soybean protein isolate and 5-30 parts of seaweed dietary fibers, wherein the soybean protein isolate and the seaweed dietary fibers are extruded and puffed in a temperature range of 100 to 130 DEG C the soybean vegetarian meat raw material containing the seaweed dietary fibers and a product thereof, disclosed by the invention, have good meat-like food chewing property and water-retaining property; and the beany flavor is remarkablyreduced and the soybean vegetarian meat raw material has a relatively good weight losing effect.

Owner:威海世纪博康海藻有限公司

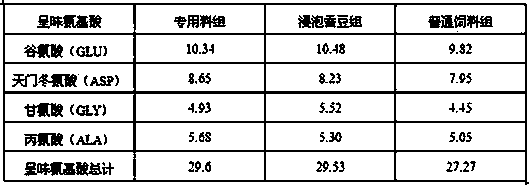

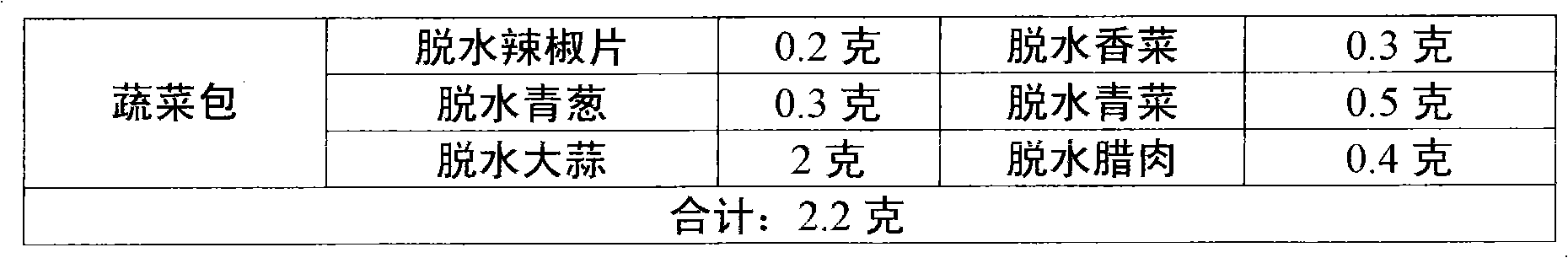

Method for preparing fermented soybean yogurt and product prepared with method

The invention discloses a method for preparing fermented soybean yogurt. The method comprises steps as follows: components of raw materials in proper parts are mixed and comprise soybean milk powder or soybean milk, essence and water; the following two-step fermentation process is performed: in the first step of fermentation, a culture is added to a raw material mixture and fermented at the temperature of 35-45 DEG C, optionally, 40-45 DEG C for 4-6 h; in the second step of fermentation: fermentation is performed at the temperature of 30-40 DEG C, optionally, 35-40 DEG C for 13-16 h.

Owner:艾地盟食品科技(北京)有限公司

Instant spicy dried bean curd

The invention discloses an instant spicy dried bean curd. The instant spicy dried bean curd is made from soybeans, purple yam, towel gourd, lemon, Reineckea carnea, elm fruit, Vitex negundo L., Herb of Ghostplant Wormwood, Astilbe chinensis, acetic acid bacteria, a spice, edible salt, maltose and a tea pigment. The instant spicy dried bean curd has the advantages of tender mouthfeel, high chewiness and elasticity, dense fragrance, spicy and tasty mouthfeel, light green color, balanced nutrition, easy absorption and comprehensive health functions, and can moisten lung, relive coughs, protect heart and cerebral vessels, prevent oxidation and ageing, enhance immunity, prevent cancers, keep youth and care skins; Chinese herbal medicines and soybean milk are boiled together to make components be fully fused, so the beany smell is eliminated; fruit and vegetable juices are fermented with the acetic acid bacteria, so absorption is promoted, the alkalinity and charges of the soybean milk are neutralized, aggregation deposition of proteins is promoted, the fruit fragrance is dense, the color of the dried bean curd is enriched, the strength of the dried bean curd is enhanced, and the dried bean curd is safe and healthy; and only a small amount of water is squeezed out, so the workload is saved, nutrition components are reserved, the water resource is saved, and the cost is reduced.

Owner:张保义

Colla corii asini natto instant powder and preparation method thereof

PendingCN109601867ABright colorGreat tasteFood mechanical treatmentFood ingredient as taste affecting agentSesamumColla corii asini

The invention discloses colla corii asini natto instant powder and a preparation method thereof, and belongs to the field of food making. The colla corii asini natto instant powder comprises the following raw materials in parts by weight of 15-20 parts of colla corii asini, 30-40 parts of soybeans, 15-25 parts of chickpeas, 5-6 parts of red jujubes, 5-6 parts of sesame seeds, 5-8 parts of yellow wine, 3-5 parts of non-dairy creamer, and 2-3 parts of edible essence. The making method of the colla corii asini natto instant powder comprises the following steps of firstly, soaking the soybeans andthe chickpeas, and then performing thorough cooking so as to obtain cooking water and cooked peas and beans; mixing the red jujubes with the colla corii asini and the sesame seeds, and performing crushing to obtain mixed powder; mixing the cooking water with the mixed powder and the yellow wine to obtain colla corii asini cream; mixing the colla corii asini cream with the cooked peas and beans, and performing fermentation to obtain colla corii asini natto; and finally, mixing the colla corii asini natto with the non-dairy creamer and the edible essence, performing crushing, and performing packing to obtain the colla corii asini natto instant powder. The colla corii asini natto instant powder disclosed by the invention is diversified in nutrient components, good in mouth feel and taste, islight in bad smell, and good in product quality.

Owner:黄绪明

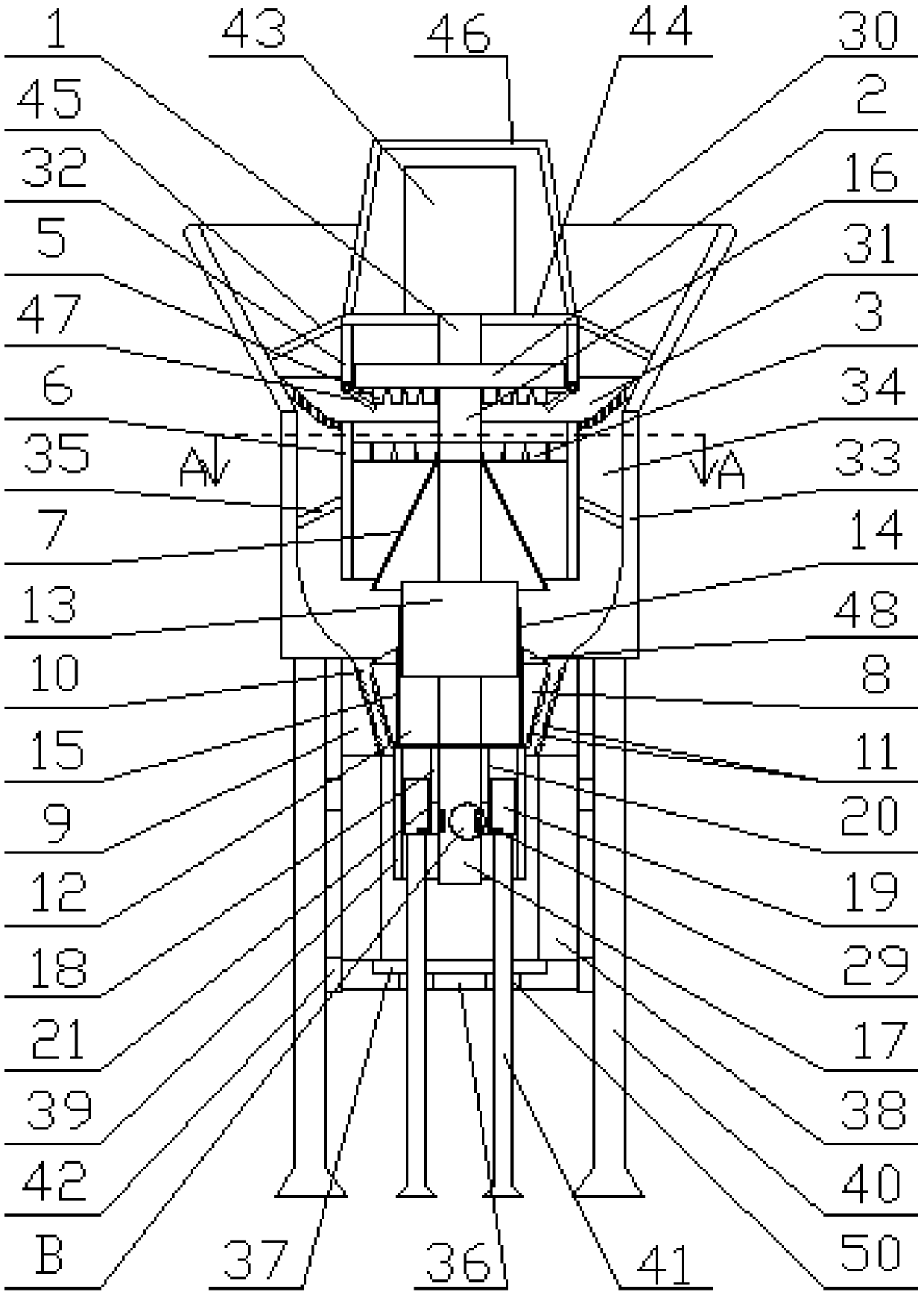

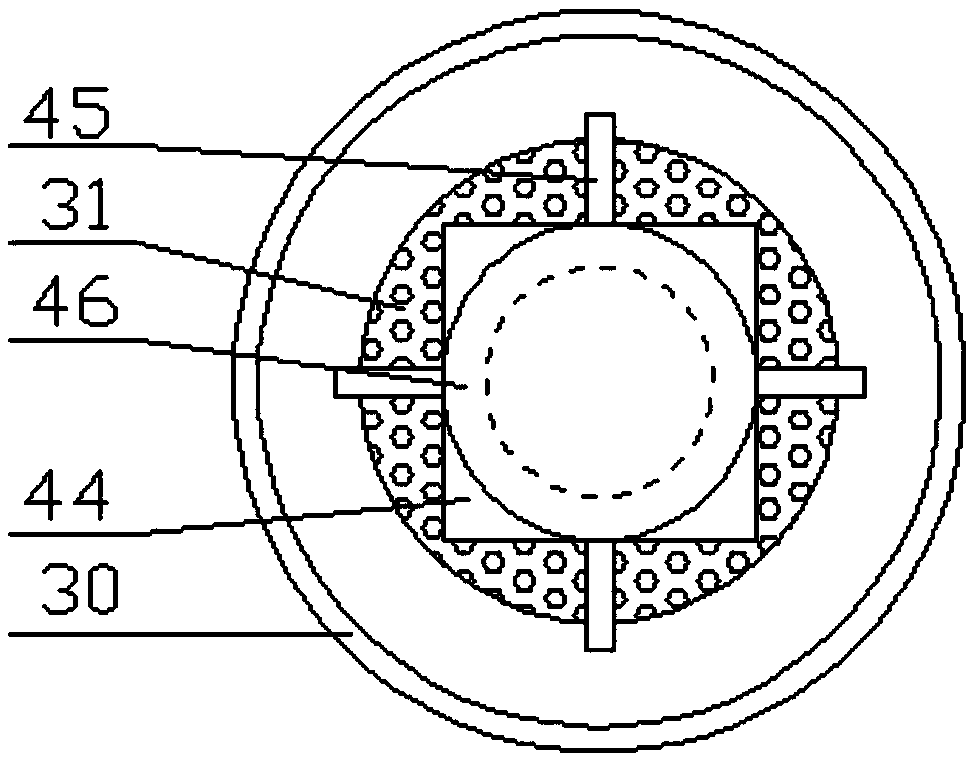

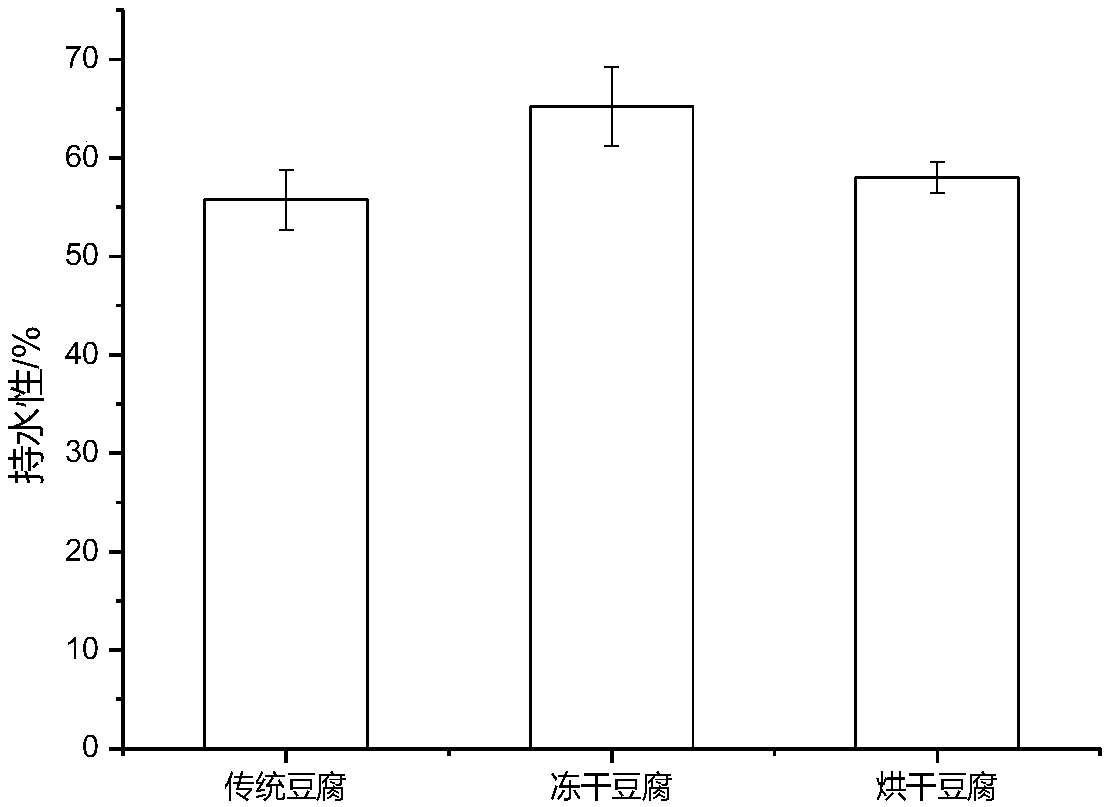

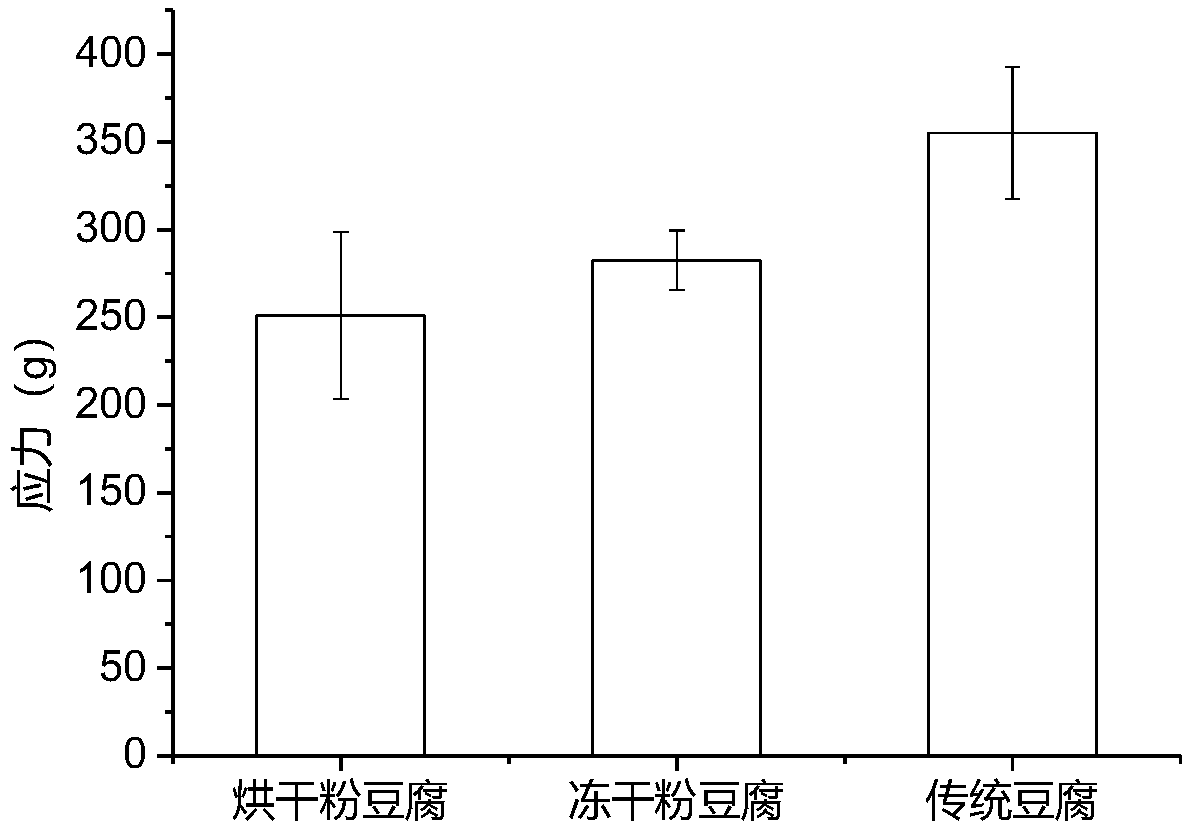

Full-bean tofu and processing method thereof

ActiveCN109619205AEasy to controlEfficient retentionCheese manufactureFood scienceFlavorFreeze-drying

The invention relates to full-bean tofu and a processing method thereof. The processing method comprises the steps of washing, soaking, peeling, smashing, slurry cooking, solidification and forming treatment, wherein before smashing, soybeans are subjected to freeze drying until the content of the moisture is not higher than 10%. According to the full-bean tofu and the processing method thereof, aphysical processing mode is adopted, parameters in the operation process are easy to control, and nutrient substances in soybean grains can be effectively and efficiently reserved. The full-bean tofuprepared by means of the processing method is high in nutrient content, unique in flavor and good in palatabibility.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Making method of soybean milk being stable and free from layering

The invention relates to a making method of soybean milk being stable and free from layering. The making method is characterized by at least comprising the following stages of (a) crushing stage: crushing water and materials into slurry; and (b) boiling stage which comprises the steps of heating the slurry to first temperature T1, and maintaining the first temperature for 2-10 minutes, and the step of continuing performing warming to second temperature T2, and maintaining the second temperature for 2-10 minutes, wherein the T1 is 65-75 DEG C, the T2 is 75-95 DEG C, and the T2 is greater than the T1. Compared with the prior art, the soybean milk is stable and free from layering, and good in mouth feel.

Owner:HONGYANG HOME APPLIANCES

Dried beancurd stick production process with soaking process simplified

InactiveCN106070696AIncrease productivityReduce manufacturing costCheese manufactureFood scienceBoiled skinSouring

The invention relates to a dried beancurd stick production process with a soaking process simplified. The production process sequentially includes following procedures: selecting beans; shelling; soaking; filtering the beans; grinding the beans into bean milk; boiling the bean milk; filtering the bean milk; boiling skin; lifting up the skin; baking; packing; obtaining a finished product. By using the dried beancurd stick production process, production efficiency of dried beancurd sticks can be effectively improved, and production cost and labor amount of working personnel can be lowered. Water changing is not needed for soaking soybeans in the soaking process, soaking time can be shortened by more than a half when compared with conventional processes, bubble rotting and souring of the soybeans are avoided, and the working personnel does not need to always observe the soaking state of the soybeans.

Owner:清流县嵩溪镇鑫牌豆腐皮厂

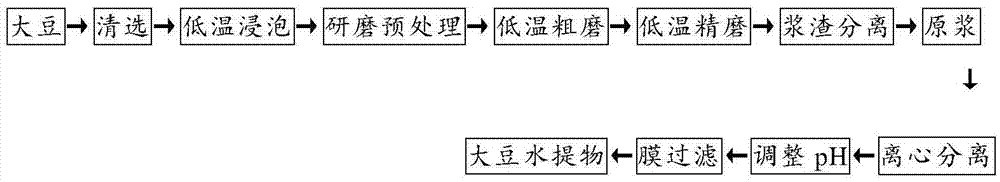

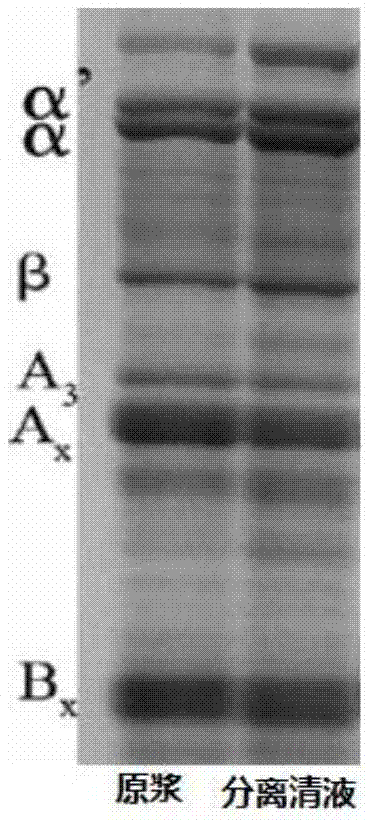

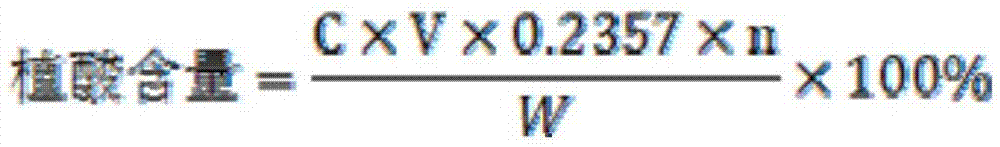

Soybean aqueous extract with low anti-nutritional components and preparation method of soybean aqueous extract

InactiveCN106923197ALow fat contentNo apparent productionFood scienceAqueous extractAnti nutritional

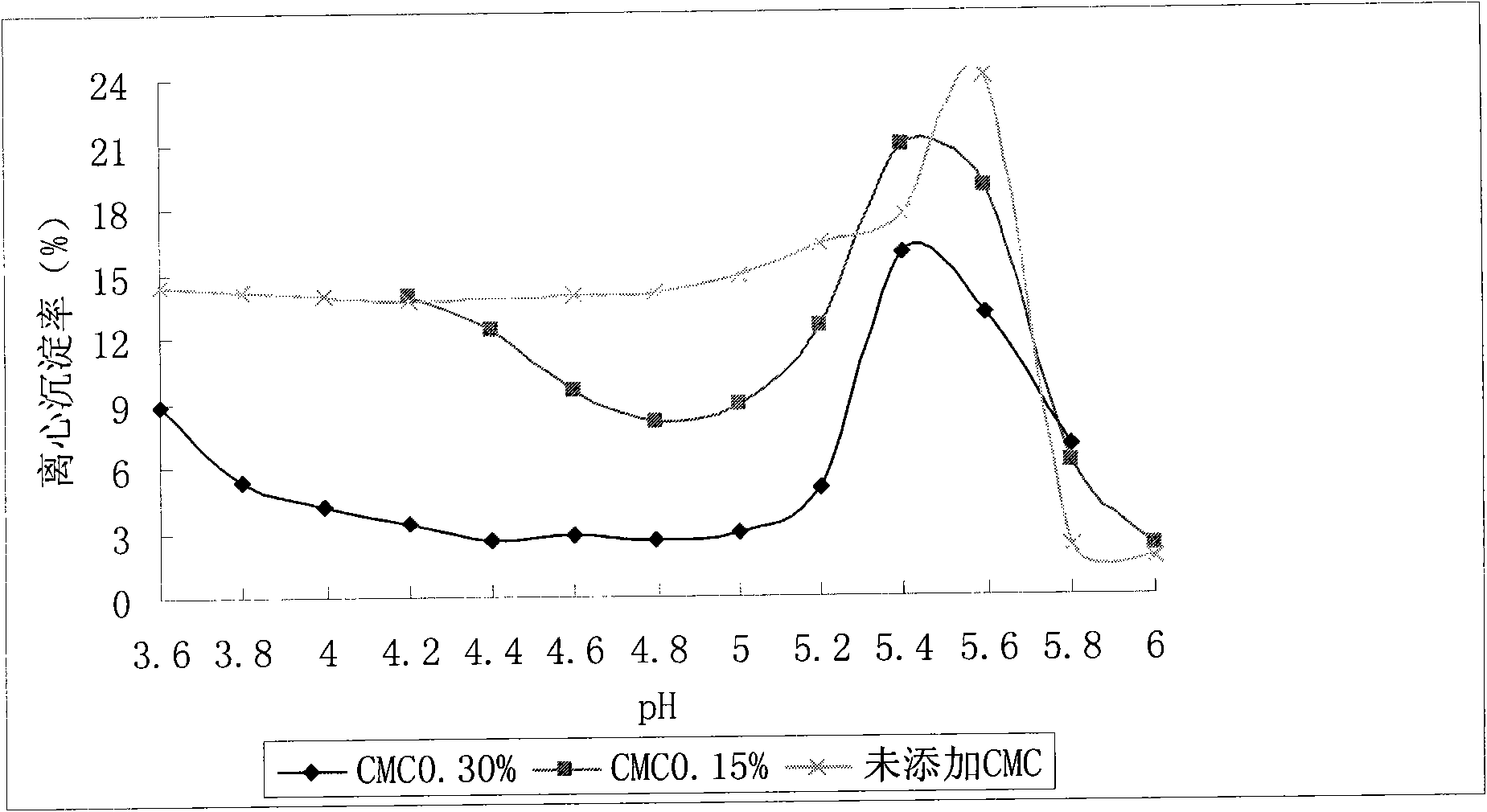

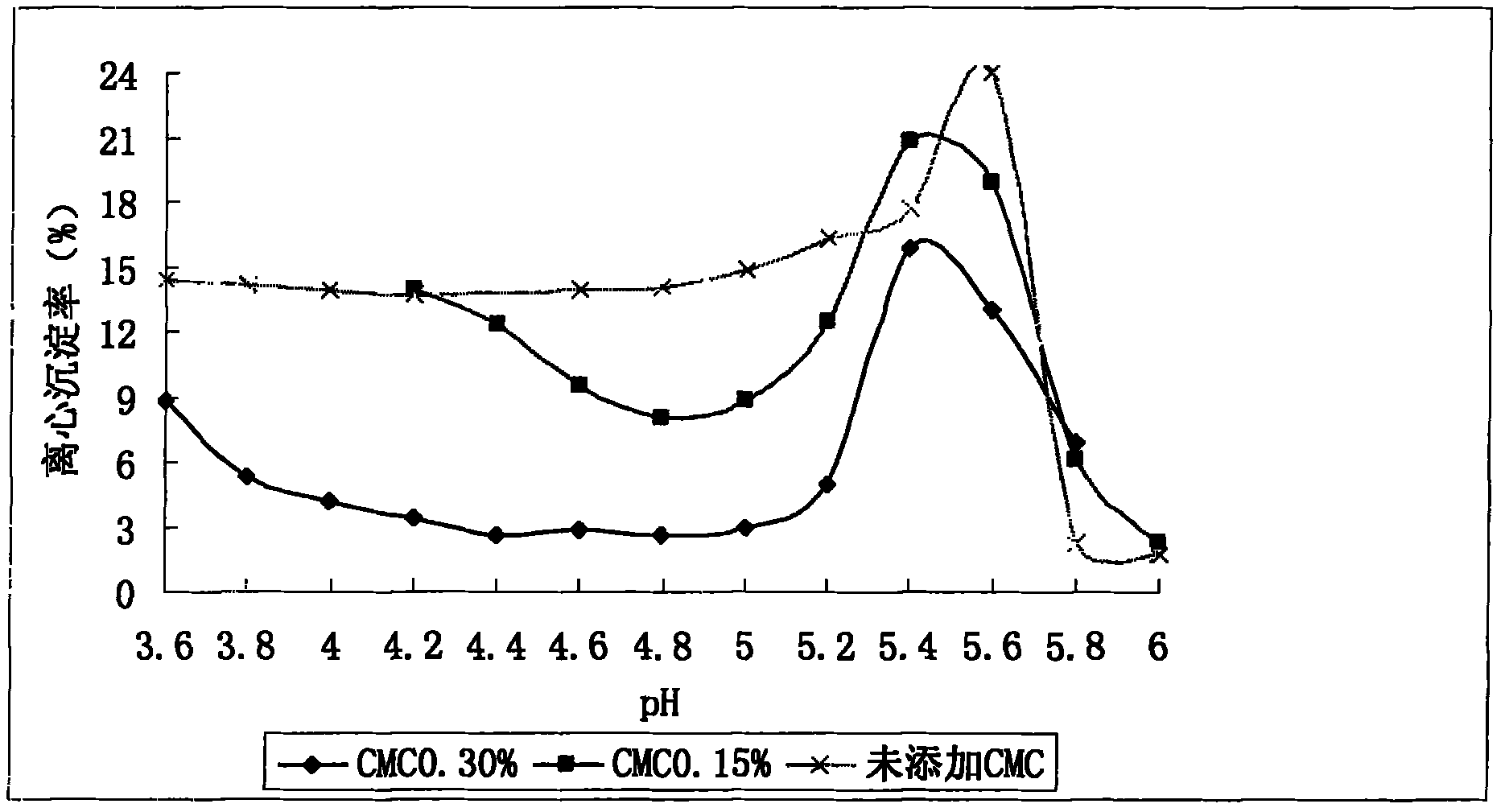

The invention relates to a soybean aqueous extract with low anti-nutritional components and a preparation method of the soybean aqueous extract. Specifically, the soybean aqueous extract has the pH ranging from 4.8 to 6.5 and the particle size Dmean ranging from 3.00 [mu] m to 16.00 [mu] m, for example, 3.29 [mu] m to 15.15 [mu] m; and / or the D90 ranging from 8.00 [mu] m to 25.00 [mu] m, for example, 8.55 [mu] m to 24.56 [mu] m. The preparation method comprises the steps as follows: providing raw soybean milk obtained after separation of milk residues; conducting centrifugal separation on the raw soybean milk to obtain a clear liquid; adjusting the pH of the clear liquid to be 6.5 or below, for example, 4.8-6.5, preferably, 5.0-6.4; and allowing the clear liquid to pass through a filter membrane with the interception value being 20,000 Dalton or below. The soybean aqueous extract obtained with the method has excellent acid resistance and anti-nutritional factors such as phytic acid can be effectively removed by the aid of the filter membrane under the acid condition.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

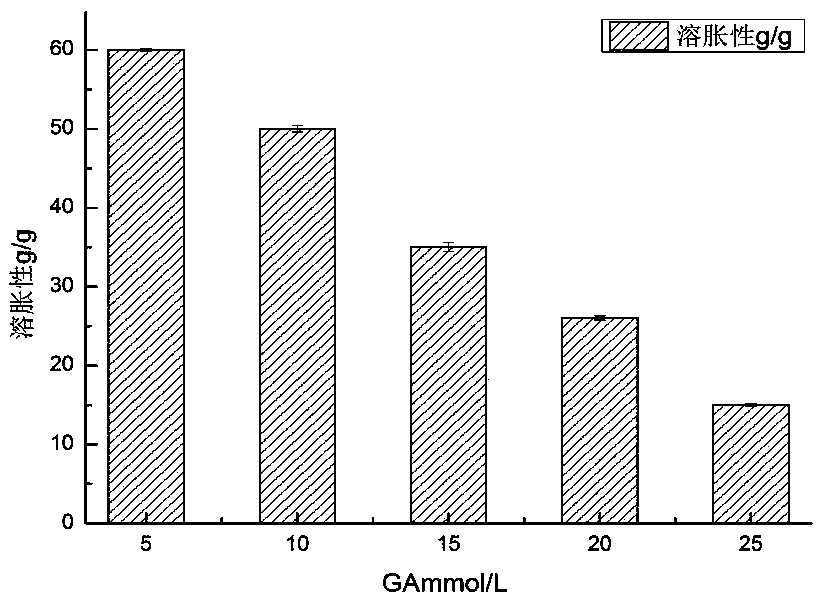

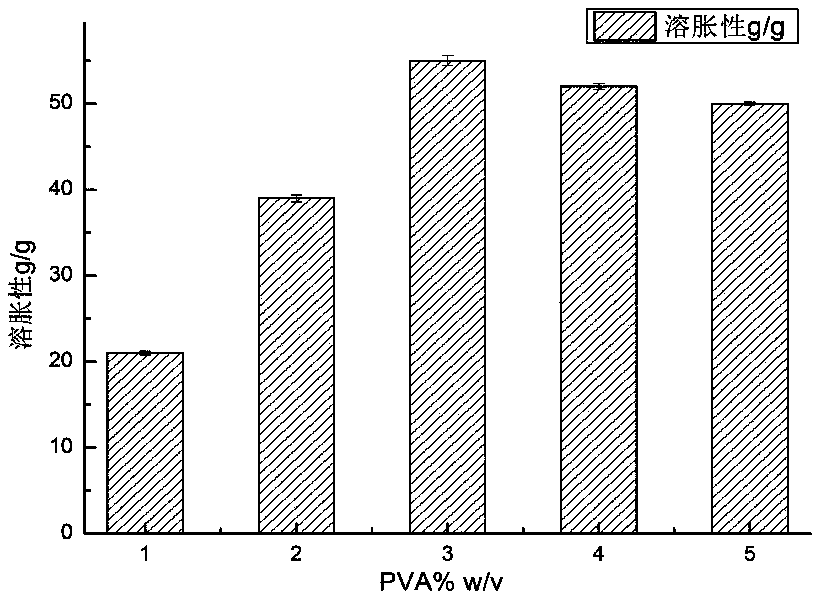

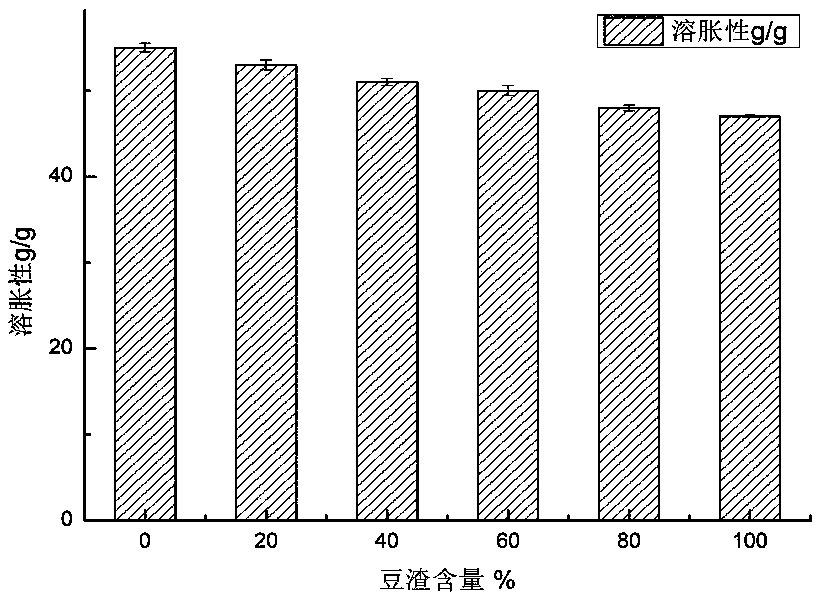

Preparation technology of bean dreg gel high in swelling property

InactiveCN109363185APromote absorptionImprove nutritional functionFood scienceFood materialMaterials processing

The invention provides a preparation technology of bean dreg gel high in swelling property, and relates to the technical field of processing of food materials. The preparation technology of bean dreggel high in swelling property mainly comprises the steps of performing crushing, performing screening, performing dissolving, adjusting PH, performing enzymolysis, performing centrifuging, performingbaking, performing mixing and cross-linking, performing ageing, performing microwave irradiation and the like. Defects in the prior art are overcome, the preparation technology of bean dreg gel high in swelling property is provided, the problems that resources are wasted and the environment is destructed caused by the condition that soybean oil fat processed residues are subjected to biological dissociation are solved, the swelling property of the bean dreg gel is increased, the utilization of soybean processing trash is realized, the environment is protected, the output value is increased, and besides, advantageous condition is created for actual production and industrialization application of the bean dreg gel.

Owner:SHANDONG YUWANG ECOLOGY FOOD IND +1

Method for preparing yuba by using soybean water enzyme method emulsion and residue

InactiveCN109169948AReduce wasteHigh in nutrientsCheese manufactureFood scienceEmulsionCentrifugation

The invention provides a method for preparing yuba by using a soybean water enzyme method emulsion and residue, and relates to the technical field of food processing. According to the present invention, the method mainly comprises: crushing, puffing, enzymolysis, deodorization, centrifugation, spray drying, blending, homogenization, heating, drying and other steps; and the method overcomes the disadvantages in the prior art, effectively improves the nutrient content of the traditional yuba product, improves the composition of the nutrients, reduces the waste of the bean residue during the production, improves the taste of the yuba, and reduces the bean odor, such that the obtained yuba has advantages of nutrition, delicious taste and the like.

Owner:SHANDONG YUWANG ECOLOGY FOOD IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com