Preparation method for peptide-containing whole bean powder, and soya-bean milk, thick soy milk and bean powder prepared by the same

A technology for soybean flour and soybean milk, applied in the field of peptide-containing whole soybean milk and peptide-containing whole soybean flour, can solve the problems of many process steps, limited beneficiary groups and high cost, achieve simple process steps, avoid environmental pollution and production costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

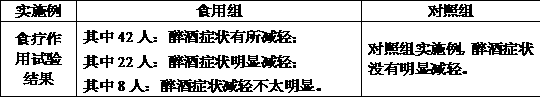

Examples

Embodiment 1

[0040] The invention discloses a method for preparing peptide-containing whole bean flour, which is prepared through the following process steps:

[0041] Step 1. Soybean raw material pretreatment: The soybean raw material used in this example is bean sprouts or germinated soybeans produced by germinating soybeans. Soybean raw materials are removed and cleaned, including removal of husk and inner testa; high-temperature cooking treatment is to boil the cleaned soybean raw materials in boiling water for 10-50 minutes, which is beneficial to passivation of harmful factors and detoxification. In addition to the soybean smell; the freezing treatment is to freeze the soybean raw material after high-temperature cooking until the inside of the raw material is completely frozen, and the freezing condition is to freeze at -10°C for 10 hours;

[0042] Step 2, thermal ultra-fine refining: The thermal ultra-fine refining in this embodiment includes the following process steps in turn: coa...

Embodiment 2

[0054] The invention provides a method for preparing peptide-containing whole bean flour, which is prepared through the following process steps:

[0055] Step 1, soybean raw material pretreatment: The soybean raw material used in this embodiment is fresh bean dregs, and the soybean raw material pretreatment process is followed by impurity removal cleaning and freezing treatment. The impurity removal cleaning is to remove foreign matter and clean the soybean raw material, including removing The husk and inner testa are removed; the freezing treatment is to freeze the cleaned and cleaned soybean raw material until the inside of the raw material is completely frozen, and the freezing condition is preferably frozen at -20°C for 8 hours;

[0056] Step 2, thermal ultra-fine refining: The thermal ultra-fine refining in this embodiment includes the following process steps in turn: coarse grinding, pulp cooking and fine grinding. The coarse grinding is to make the soybean raw material p...

Embodiment 3

[0068] The invention provides a method for preparing peptide-containing whole bean flour, which is prepared through the following process steps:

[0069] Step 1, pretreatment of soybean raw materials: the soybean raw materials used in this embodiment are soybeans and brown rice, and the weight ratio of soybeans to brown rice is 1:1. The soybean raw material pretreatment of this embodiment first germinates soybeans and brown rice. Soybeans and brown rice are germinated at a temperature of 30°C after cleaning. When the germination reaches 2-5 mm, the germination treatment is stopped, and then the pretreatment process of soybean raw materials is followed by impurity removal and microwave treatment. Raw materials are removed and cleaned, including removal of husk and inner testa; microwave treatment is to place the cleaned and cleaned soybean raw materials in microwave sterilization equipment, control the microwave power to 10-40KW, and the frequency to 2000 MHz -3000MHz, temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com