Organic light emitting diode and manufacturing method thereof and display device

A technology for light-emitting diodes and a manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve the problems of difficult carrier balance and difficult material selection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

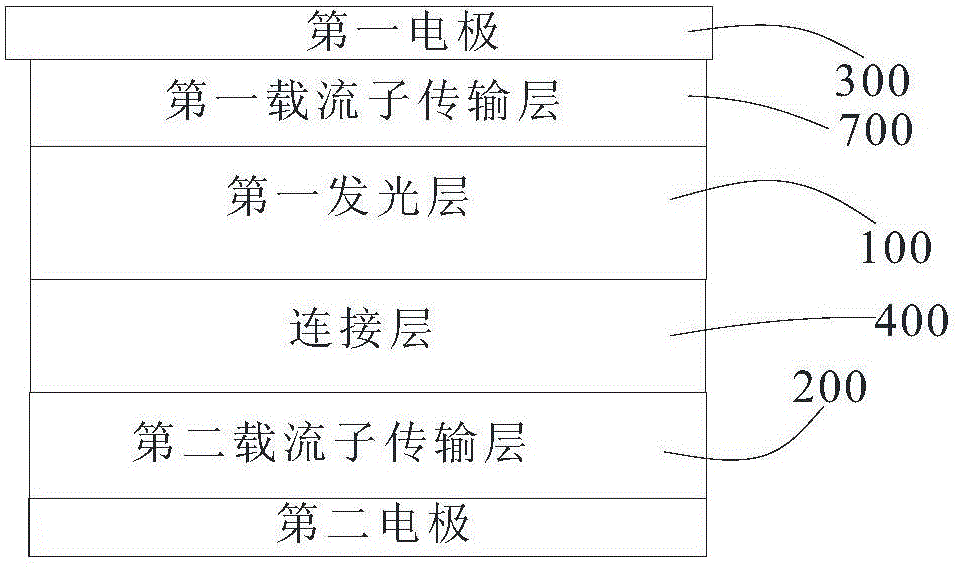

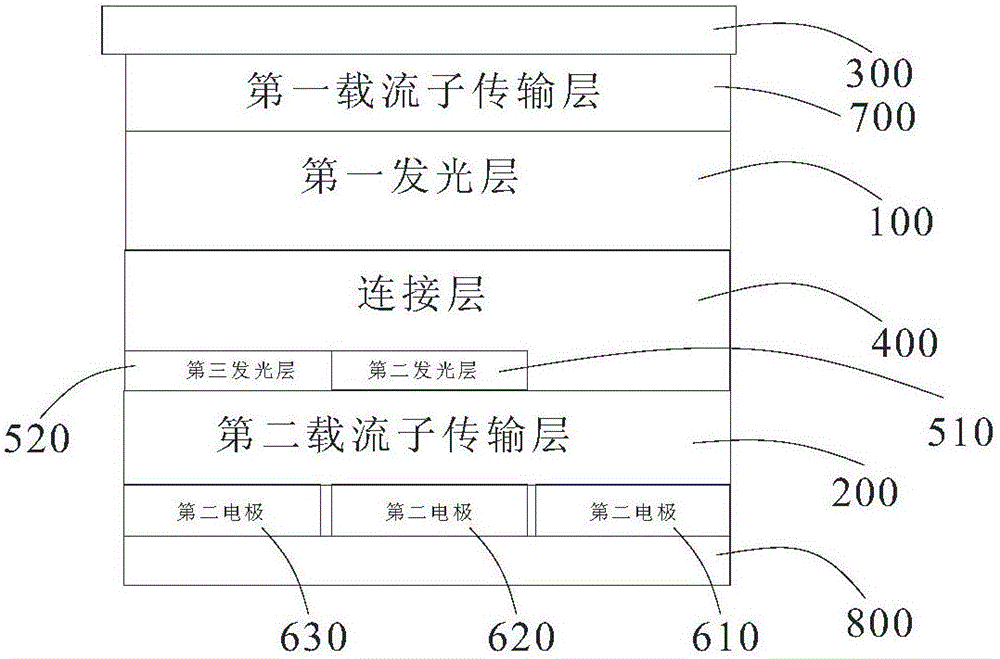

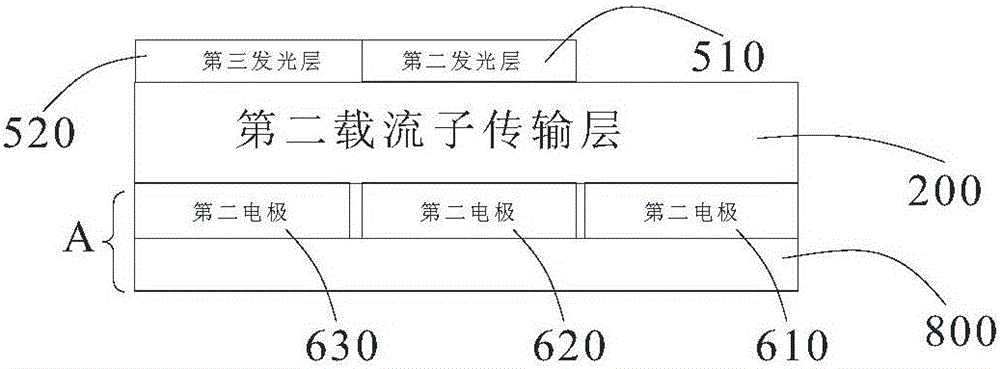

[0104] Organic Light Emitting Diodes have figure 2 In the structure, the first electrode 300 is a cathode, the first carrier transport layer 700 is an electron transport layer, the first light emitting layer 100 is a blue light emitting layer, the second light emitting layer 510 is a red light emitting layer, and the third light emitting layer 510 is a red light emitting layer. Layer 520 is a blue light-emitting layer, the second carrier transport layer 200 is a hole transport layer, the second electrode is an anode, and the thickness of the connection layer 400 is 1 nm.

Embodiment 2

[0106] The organic light emitting diode has the same structure as that of the organic light emitting diode in Embodiment 1, except that the connection layer 400 has a thickness of 5 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com