A kind of self-luminous fluorescent microsphere and preparation method thereof

A technology of fluorescent microspheres and self-luminescence, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems affecting the luminescence performance and service life of microspheres, the loss of dyes or quantum dots, and the lack of autofluorescence, etc., to achieve structural Regular, long-lasting luminous effect, not easy to quench

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Add 1.0 g of phenol, 5 mL of formaldehyde and 40 mL of distilled water into a three-necked flask, mix them uniformly by ultrasonic, stir at 250 r / min, and raise the temperature to 80 o C, keep warm for 30 min.

[0028] (2) Add 4 mL of ammonia water to the pre-reaction solution obtained in step (1). After 24 h of reaction, add 1 mol / L hydrochloric acid solution to adjust the pH to neutral, and cool the reaction system to room temperature.

[0029] (3) The product of step (2) was centrifuged at 5000 r / min, washed three times with distilled water, ethanol, and distilled water, and finally dried in a vacuum oven for 4 h.

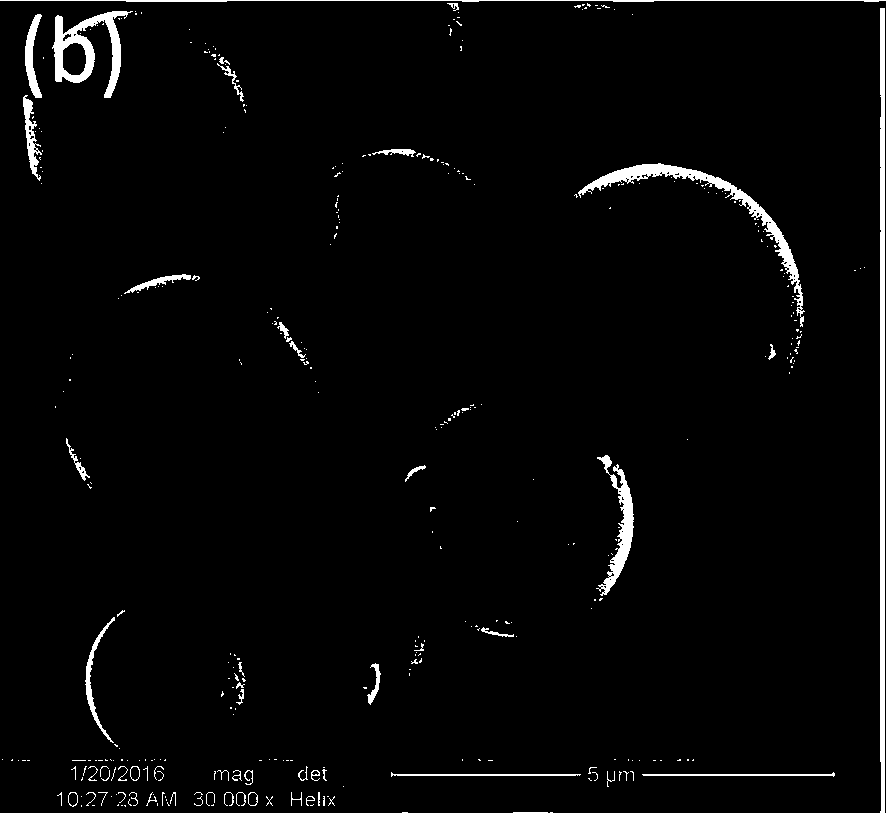

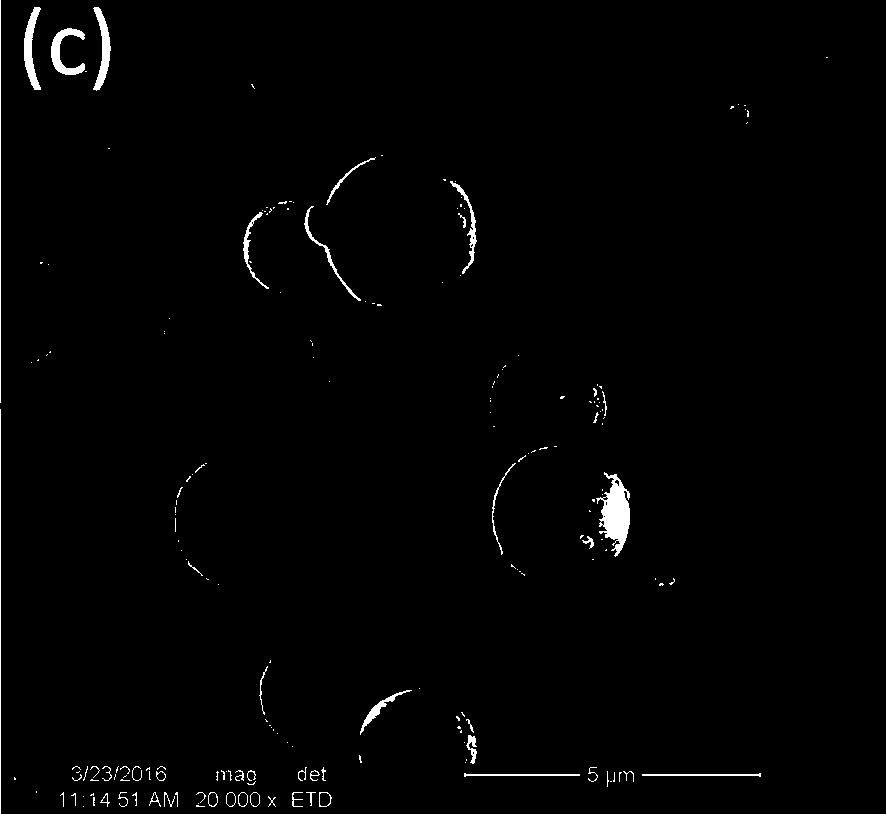

[0030] The particle size of the prepared self-luminous fluorescent microspheres was 4.5 µm.

Embodiment 2

[0032] (1) Add 1.0 g of phenol, 5 mL of formaldehyde and 40 mL of distilled water into a three-necked flask, mix them uniformly by ultrasonic, stir at 250 r / min, and raise the temperature to 80 o C, keep warm for 30 min.

[0033] (2) Add 6 mL of ammonia water to the pre-reaction solution obtained in step (1). After 24 h of reaction, add 1 mol / L hydrochloric acid solution to adjust the pH to neutral, and cool the reaction system to room temperature.

[0034] (3) The product of step (2) was centrifuged at 5000 r / min, washed three times with distilled water, ethanol, and distilled water, and finally dried in a vacuum oven for 4 h.

[0035] The particle size of the prepared self-luminous fluorescent microspheres was 3 µm.

Embodiment 3

[0037] (1) Add 1.0 g of phenol, 5 mL of formaldehyde and 40 mL of distilled water into a three-necked flask, mix them uniformly by ultrasonic, stir at 250 r / min, and raise the temperature to 80 o C, keep warm for 30 min.

[0038] (2) Add 8 mL of ammonia water to the pre-reaction solution obtained in step (1). After 24 h of reaction, add 1 mol / L hydrochloric acid solution to adjust the pH to neutral, and cool the reaction system to room temperature.

[0039] (3) The product of step (2) was centrifuged at 5000 r / min, washed three times with distilled water, ethanol, and distilled water, and finally dried in a vacuum oven for 4 h.

[0040] The particle size of the prepared self-luminous fluorescent microspheres was 2.5 µm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com