An Atmospheric Pressure Microwave Plasma Excitation Source Device and Its Application

A technology of microwave plasma and excitation source, which is applied in the field of chemical measurement, can solve the problems of prolonging sample analysis time, requirement of sample shape, insufficient ionization ability, etc., and achieve the effects of not easy quenching, strong sample tolerance, and reduced interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

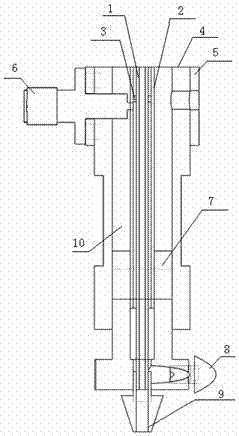

[0035] see figure 1 , an atmospheric pressure microwave plasma excitation source device consists of an inner tube 1, a middle tube 2, a calibration pad 3, an outer tube 4, a microwave feed-in interface 5, a coaxial cable SMA connector 6, a tuning piston 7, and a side gas inlet port 8, the lower end gas inlet port 9, composed of coaxial channel 10.

[0036] The middle tube 2 is located between the inner tube 1 and the outer tube 4, the calibration pad 3 is fixed between the inner tube 1 and the middle tube 2, and the coaxial cable SMA connector 6 is fixed on the microwave feed-in interface by screws (not shown in the figure) 5, the inner hole of the microwave feed-in interface 5 is tightly fitted with the outer tube 4, and the bolt is fastened to the fixing screw hole 14 of the microwave feed-in interface of the outer tube through the microwave feed-in interface fixing hole 20 on the microwave feed-in interface 5. The axial cable SMA connector 6 passes through the outer tube 4...

Embodiment 2

[0049] Embodiment 2 Working process of the present invention

[0050] Open the gas flow meter, the gas inlet hose is fixed on the gas introduction pipe joint 33, the middle pipe 2 is fixed on the middle pipe fixing interface 30 through its bottom thread, and the inner pipe 1 is fixed on the lower end gas introduction port 9 through the threaded end surface 11 On the fixed thread 32 of the inner inner tube, a calibration pad 3 is added between the inner tube 1 and the middle tube 2 to compensate for mechanical assembly errors, and at the same time, the gas in the middle tube 2 enters the reaction area through the exhaust hole 12 . Control the gas flow in the middle tube 2 and the inner tube 1, and select the appropriate helium (or argon) flow rate. Turn on the microwave source to generate 5.8Ghz microwave energy, and connect the output port of the microwave source to the microwave coaxial connection screw port 23 on the SMA connector 6 of the coaxial cable through a 50Ω coaxial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com