Foamless anti-phenolic yellowing agent as well as preparation method and application thereof

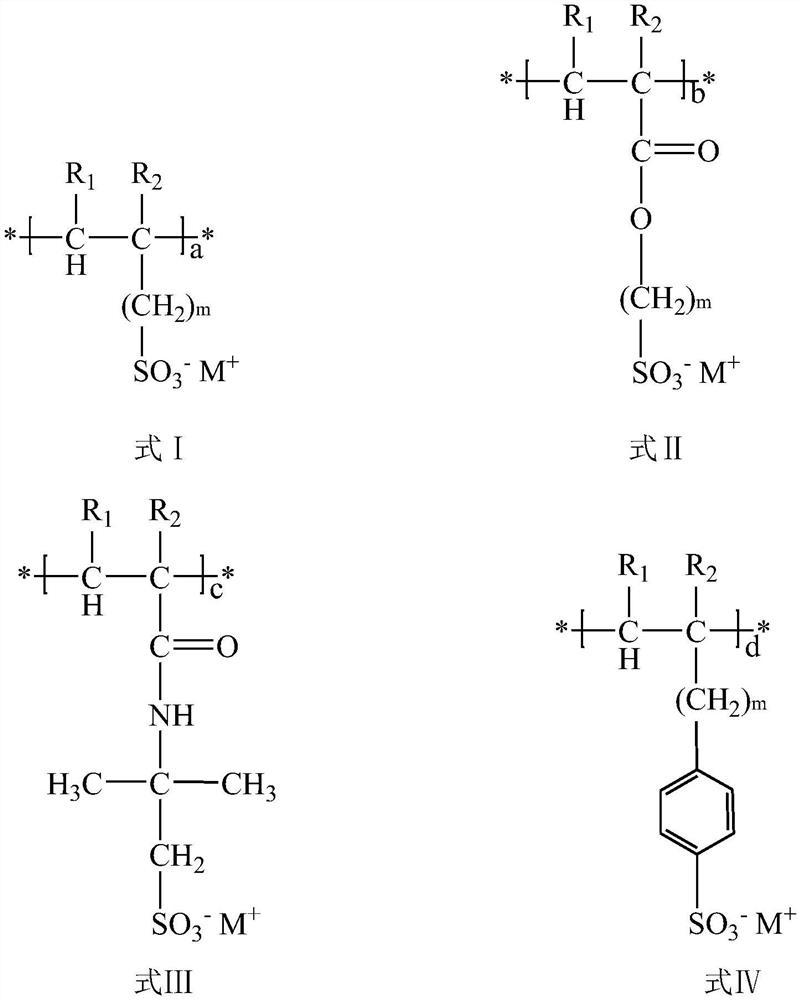

A technology of anti-phenol yellowing agent and sulfonic acid group, which is applied in the field of non-foaming anti-phenol yellowing agent and its preparation, can solve the problems such as being difficult to wash off, and achieve not easy color change, little color influence, and excellent anti-phenol yellowing The effect of sex change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Add 29.6 parts of propylene sulfonic acid, 10.4 parts of methacrylic acid, 0.3 parts of sodium bisulfite and 36 parts of deionized water into a reactor equipped with a stirrer, thermometer, balance feeder and condenser; then add 8 parts of ammonium persulfate Add the aqueous solution (the mass concentration of ammonium persulfate is 10%) into the balance feeder of the reaction device; start stirring, and control the rotating speed at 200 rpm; Add ammonium persulfate aqueous solution dropwise. After the dropwise addition is completed within 0.5 hours, raise the temperature to 85°C and continue the heat preservation reaction for 5 hours; Slowly add 16 parts of triethanolamine, continue the heat preservation reaction for 2 hours, control the temperature of the reaction solution to not exceed 70°C, then adjust the pH value of the reaction product to 4.0 with acetic acid, then cool down to below 50°C and discharge, and the foam-free Anti-phenolic yellowing agent.

[0066] I...

Embodiment 2

[0068] Add 26 parts of methacrylic acid and 35 parts of deionized water into the reactor with stirrer, thermometer, balance feeder and condenser; add 14 parts of acrylic acid into the balance feeder of the reaction device; add 10 parts Sodium persulfate aqueous solution (the mass concentration of sodium persulfate is 20%) adds in another balance feeder of reaction unit; Open stirring, control rotating speed at 180 revs / min; After 75°C, start to add acrylic acid and sodium persulfate aqueous solution dropwise at the same time, after about 3 hours after the dropwise addition, raise the temperature to 85°C, and continue the heat preservation reaction for 6 hours; , after cooling down to 40°C, slowly add 12 parts of deionized water, 3.5 parts of diethylamine and 6.5 parts of monoethanolamine, continue the heat preservation reaction for 2 hours, adjust the pH value of the reaction product to 6.5-7.0, and then add 3 parts of citric acid After adjusting the pH value of the reaction p...

Embodiment 3

[0071] Add 29.5 parts of methacrylic sulfonic acid, 6.5 parts of 3-sulfonic acid propyl methacrylate potassium salt, 4 parts of acrylic acid, 0.2 parts of sodium bisulfite and 25 parts of deionized water into the feeder with agitator, thermometer and balance And in the reactor of condenser; Then 24 parts of ammonium persulfate aqueous solution (mass concentration of ammonium persulfate is 5%) add in another balance feeder of reaction device; Open stirring, control rotating speed at 150 rev / min; Open The heating device raises the temperature of the material in the reactor. After the temperature rises to 65°C, the ammonium persulfate aqueous solution is added dropwise. After the dropwise addition is completed in about 4 hours, the temperature is raised to 90°C, and the heat preservation reaction is continued for 4 hours; The reaction solution in the reactor was cooled down to 30°C, and then 14.5 parts of deionized water and 8.5 parts of diethanolamine were added to adjust the pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com