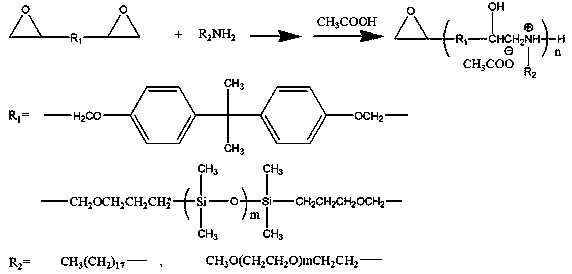

Preparation method of cationic amino modified epoxy silicone oil and compounding and application of polyacrylonitrile carbon fiber precursor oil agent

A technology of epoxy silicone oil and amino modification, which is applied in fiber type, fiber treatment, textile and paper making, etc., and can solve the problems of good storage stability of emulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

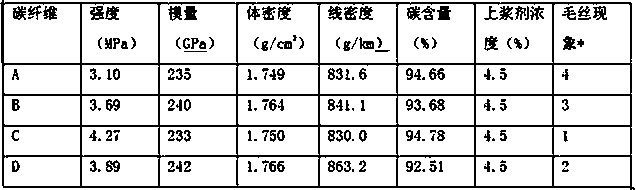

Examples

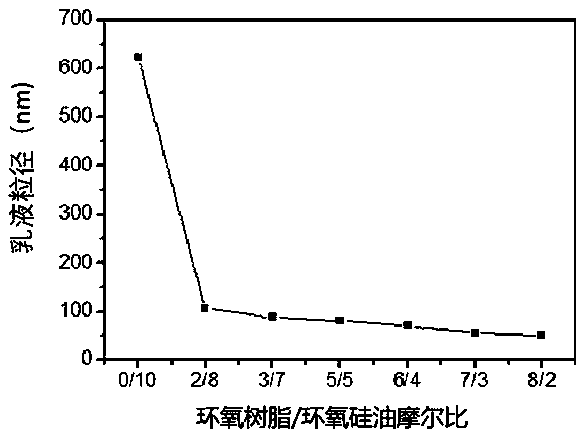

Embodiment 1

[0084] Use 50g of N-methylpyrrolidone (NMP) to mix 30.78g of octadecylamine and 12.69g of polyetheramine (molecular weight: 1000), install the sealing and condensing device, and then pass in nitrogen gas, set the temperature at 50°C, and wait until the temperature reaches 50°C ℃ and stabilized for ten minutes, add the water separator, set the temperature to 80 ℃, after the temperature is constant, add 81.53g of epoxy silicone oil, slowly raise the temperature to 110 ℃, react for 2.5 hours, cool down to room temperature, add Add 6.85g of glacial acetic acid to emulsify with 215g of water. The cationic amino-modified epoxy silicone oil emulsion has a molecular weight of 5000, a particle size of 622.59nm, and a silicone oil content of 32%. The emulsion was stored at room temperature for 6 months or 3000 rpm / centrifuge for 30 minutes without precipitation.

Embodiment 2

[0086] Use 50g of N-methylpyrrolidone (NMP) to mix 28.66g of octadecylamine and 11.82g of polyetheramine (molecular weight: 1000). After installing the sealing and condensing device, nitrogen gas is introduced, and the temperature is set at 50°C until the temperature reaches 50°C. ℃ and stabilized for ten minutes, add the water separator, set the temperature to 80 ℃, after the temperature is constant, add 84.52g of epoxy silicone oil, slowly raise the temperature to 110 ℃, react for 2.5 hours, cool down to room temperature, add Add 6.38g of glacial acetic acid to emulsify with 215g of water. The cationic amino-modified epoxy silicone oil emulsion has a molecular weight of 10,000, a particle size of 193.97nm, and a silicone oil content of 32%. The emulsion was stored at room temperature for 6 months or 3000 rpm / centrifuge for 30 minutes without precipitation.

Embodiment 3

[0088] Use 50g of N-methylpyrrolidone (NMP) to mix 27.60g of octadecylamine and 11.38g of polyetheramine (molecular weight: 1000). After installing the sealing and condensing device, nitrogen gas is introduced, and the temperature is set at 50°C until the temperature reaches 50°C. ℃ and stabilized for ten minutes, add the water separator, set the temperature to 80 ℃, after the temperature is constant, add 86.02g of epoxy silicone oil, slowly raise the temperature to 110 ℃, react for 2.5 hours, cool down to room temperature, add Add 6.14g of glacial acetic acid to emulsify with 215g of water. The cationic amino-modified epoxy silicone oil emulsion has a molecular weight of 20,000, a particle size of 173.42nm, and a silicone oil content of 32%. The emulsion was stored at room temperature for 6 months or 3000 rpm / centrifuge for 30 minutes without precipitation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com