Organophosphorus hybrid alpha-ZrP flame-retardant material and preparation method thereof

A technology of flame retardant materials and hybrid materials, which is applied in the field of organophosphorus hybrid α-ZrP flame retardant materials and their preparation, can solve the problems of poor thermal stability, small amount of modifiers, difficult fiber-forming processing, etc. High heat-resistant temperature and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

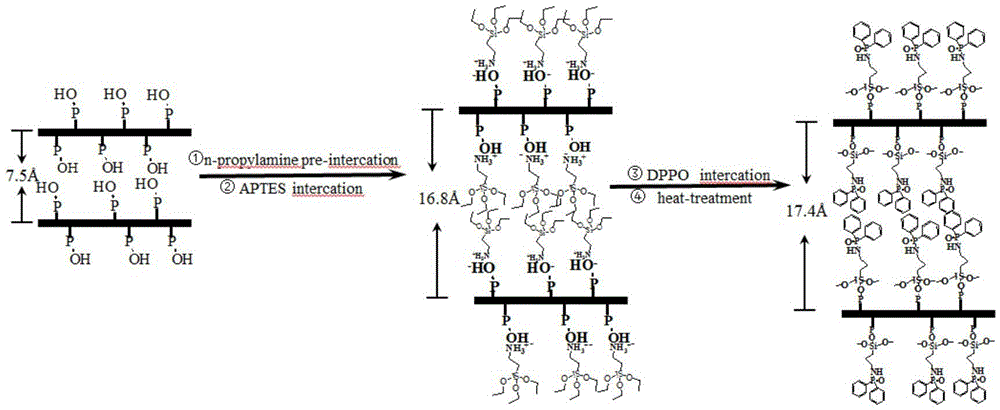

[0043] A preparation method of organophosphorous hybridized α-ZrP flame retardant material, such as figure 1 Shown is a schematic diagram of the process of preparing organically modified α-ZrP, in which α-ZrP is pre-intercalated with n-propylamine (n-propylamine), and then contacted with 3-aminopropyl-triethoxysilane (APTES). branching reaction, and then diphenylphosphine reacts with the end groups of the silane coupling agent on the surface of α-ZrP and between the layers, and finally undergoes heat treatment (heat-treatment) to obtain an organophosphorus hybrid α-ZrP flame retardant material, the steps are: :

[0044] 1) Disperse α-ZrP in tetrahydrofuran solution with ultrasonic and mechanical stirring at room temperature, ultrasonic power is 50W, time is 20min; mechanical stirring speed is 200r / min, time is 20min, and the concentration of α-ZrP after dispersion is 0.005g / ml;

[0045] 2) Add small molecule n-propylamine to react, the molar ratio of n-propylamine to α-ZrP i...

Embodiment 2

[0051] A preparation method of organophosphorous hybridized α-ZrP flame retardant material, the steps are:

[0052] 1) Disperse α-ZrP in chloroform with ultrasonic and mechanical stirring at room temperature, the ultrasonic power is 90W, and the time is 50min; the speed of mechanical stirring is 800r / min, and the time is 50min. The concentration is 0.02g / ml;

[0053] 2) Add small molecule ethylamine to react, the molar ratio of ethylamine to α-ZrP is 1:4.0, and the reaction time of adding ethylamine is 1.8h;

[0054]3) Add dropwise silane coupling agent 3-aminopropyl-trimethoxysilane (APTMS) to continue the reaction; the mass ratio of the amount of APTMS added to α-ZrP is 2:1; the rate of addition is 1.5ml / min; The time to continue the reaction is 8h;

[0055] 4) Add methylphosphonic acid to continue the reaction; the molar ratio of the amount of methylphosphonic acid added to APTMS is 1.5:1; the reaction temperature is 60°C, and the reaction time is continued for 5h;

[00...

Embodiment 3

[0059] A preparation method of organophosphorous hybridized α-ZrP flame retardant material, the steps are:

[0060] 1) Disperse α-ZrP in DMF with ultrasonic and mechanical stirring at room temperature, ultrasonic power is 60W, time is 30min; mechanical stirring speed is 500r / min, time is 30min, and the concentration of α-ZrP after dispersion is 0.008g / ml;

[0061] 2) Add small molecule n-propylamine to react, the molar ratio of n-propylamine to α-ZrP is 1:2.2, and the reaction time of adding n-propylamine is 0.9h;

[0062] 3) Drop the silane coupling agent 3-aminopropyl-triethoxysilane (APTES) to continue the reaction; the mass ratio of the amount of APTES added to α-ZrP is 1.0:1; the rate of addition is 1.2ml / min ; The time to continue the reaction is 5h;

[0063] 4) Add methylphosphonodichloride to continue the reaction; the molar ratio of the amount of methylphosphonodichloride added to APTES is 2:1; the reaction temperature is 40°C, and the reaction time is continued for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com