Long glass fiber reinforced polyketone material and preparation method thereof

A technology of long glass fiber and polyketone, which is applied in the field of long glass fiber reinforced polyketone material and its preparation, can solve the problems of few literature reports, and achieve the effects of excellent mechanical properties, high production capacity, and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

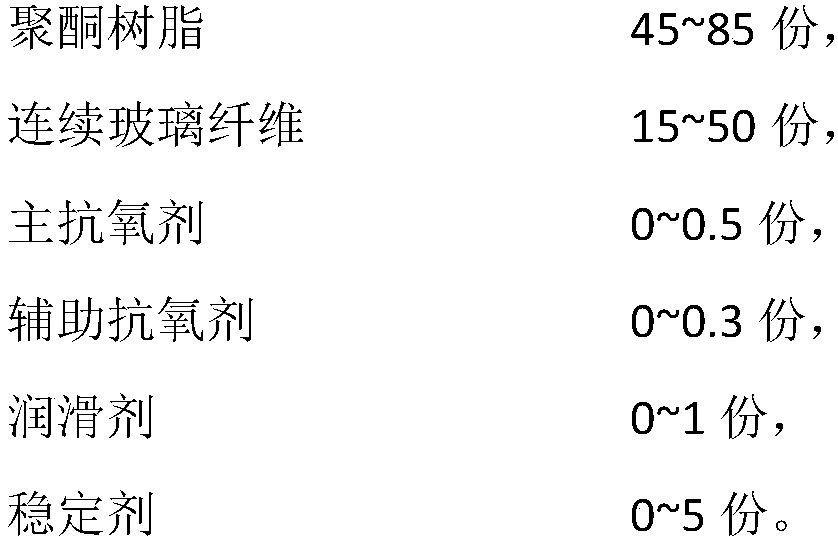

Method used

Image

Examples

Embodiment 1

[0026] Polyketone 45 parts,

[0027] Continuous glass fiber 15 parts,

[0028] Among them, polyketone is selected from Hyosung's high-end mobile brand Shell DP R1000, the melt flow rate is 90g / 10min, the test condition is 240℃, 2.16kg;

[0029] The continuous glass fiber is selected from continuous non-alkali glass fiber with a fiber diameter of 10 μm and a linear density of 1000 tex.

[0030] ⑴ Mixing preparation: Add 45 parts of polyketone into the high mixer, control the mixing temperature at 40°C, stop mixing after 2 minutes, and then add the mixed material into the barrel of the extruder;

[0031] ⑵Preparation of polyketone composite materials: using impregnation equipment for continuous fiber reinforced thermoplastic materials, adding polyketone resin into the twin-screw extruder for heating and melting, and extruding the melt into the impregnation mold connected to the head of the twin-screw extruder In the process, the continuous glass fiber enters the impregnation...

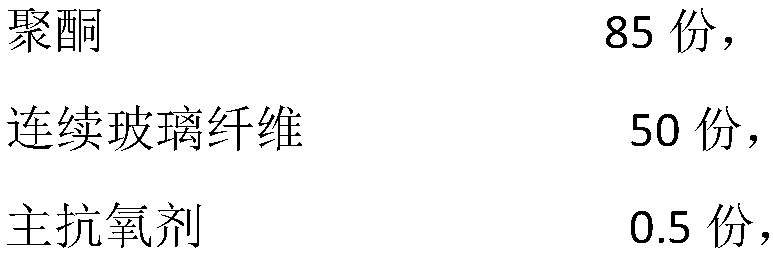

Embodiment 2

[0039]

[0040]

[0041] Among them, the polyketone selected from Korea Hyosung’s advanced flow grade is M130A, the melt flow rate is 200g / 10min, and the test condition is 240°C, 2.16kg;

[0042] The continuous glass fiber is selected from continuous alkali-free glass fiber, the fiber diameter is 22μm, and the linear density is 4800tex;

[0043] The main antioxidant is selected from antioxidant 1076;

[0044] Auxiliary antioxidant is selected from the antioxidant 697 of BASF;

[0045] The lubricant is selected from a mixture of silicones, polyethylene waxes and pentaerythritol stearate;

[0046] The stabilizer is aluminum phosphate treated with 0.5% PEG-600.

[0047] ⑴ Mixing preparation: first add aluminum phosphate into a small high mixer, and add PEG-600 with 0.5% weight fraction of aluminum phosphate while stirring. After adding, stir for another 5 minutes and take it out for use; Propylene, 0.5 parts of primary antioxidant, 0.3 parts of auxiliary antioxidant, and...

Embodiment 3

[0052]

[0053]

[0054] Among them, the polyketone is selected from Korea Hyosung's medium and low flow grade M630A, the melt flow rate is 6g / 10min, and the test condition is 240°C, 2.16kg;

[0055] The continuous glass fiber is selected from continuous non-alkali glass fiber, the fiber diameter is 17μm, and the linear density is 2400tex;

[0056] The main antioxidant is selected from antioxidant 1098;

[0057] Auxiliary antioxidant is selected from MD1024 of BASF;

[0058] The lubricant is selected from a mixture of ethylene bisstearamide EBS, calcium stearate, silicone and polyethylene wax.

[0059] ⑴ Mixing preparation; add 69.1 parts of polypropylene, 0.2 parts of primary antioxidant, 0.2 parts of auxiliary antioxidant, and 0.5 parts of lubricant into the high-speed mixer in sequence. The mixing temperature is controlled at 50 ° C. After mixing for 3 minutes Stop, then add the mixed material to the extruder barrel;

[0060] ⑵Preparation of polyketone composite ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com