Preparation process of color paint steel plate

A preparation process and technology of steel plates, applied in the field of preparation technology of color-painted steel plates, can solve the problems of difficult large-area construction, poor metal adhesion, long curing time, etc., and achieve excellent adhesion and workability, increase hardness, and excellent resistance. solvent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

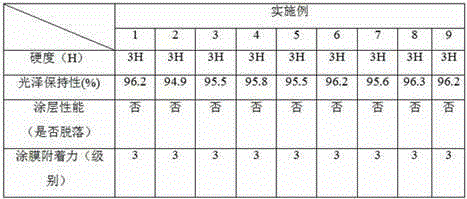

Examples

Embodiment 1

[0024] The color-painted steel sheet involved in this embodiment is obtained by applying a primer coating to a pre-coated steel sheet and baking it sequentially, wherein the primer coating is applied to the surface layer of the pre-coated steel sheet to form a primer coating film , by weight percentage, described primer paint comprises the following components:

[0025] Saturated carboxylated polyester: 30%; Filler: 15%;

[0026] Silicone coupling agent: 1%; Phthalate: 0.5%;

[0027] Predispersed pigment preparation: 1.5%; xylene solvent: 52%.

[0028] The following is a further description of the composition of the above components:

[0029] Saturated carboxylated polyester: solid content is 58%, specific gravity is 2.05, acid value is 12mgKOH / g.

[0030] Filler: including lead glass powder, dichromium trioxide and china clay, by weight percentage, lead glass powder is 10%, dichromium oxide is 2%, and china clay is 3%.

[0031] Pre-dispersed pigment preparation: It is pre...

Embodiment 2

[0035] The color-painted steel sheet involved in this embodiment is obtained by applying a primer coating to a pre-coated steel sheet and baking it sequentially, wherein the primer coating is applied to the surface layer of the pre-coated steel sheet to form a primer coating film , by weight percentage, described primer paint comprises the following components:

[0036] Saturated carboxylated polyester: 30%; Filler: 40%;

[0037] Silicone coupling agent: 1%; Phthalate: 0.5%;

[0038] Predispersed pigment preparation: 1.5%; xylene solvent: 52%.

[0039] The following is a further description of the composition of the above components:

[0040] Saturated carboxylated polyester: solid content is 62%, specific gravity is 2.8, acid value is 15mgKOH / g.

[0041] Filler: including boron glass powder, chromium oxide, china clay, aluminum powder and talcum powder, by weight percentage, filler includes: 30% boron glass powder, 2% chromium oxide, 3% china clay, 4% aluminum powder and ...

Embodiment 3

[0047] The color-painted steel sheet involved in this embodiment is obtained by applying a primer coating to a pre-coated steel sheet and baking it sequentially, wherein the primer coating is applied to the surface layer of the pre-coated steel sheet to form a primer coating film , by weight percentage, described primer paint comprises the following components:

[0048] Saturated carboxylated polyester: 40%; Filler: 40%;

[0049] Silicone coupling agent: 1%; Phthalate: 1%;

[0050] Predispersed pigment preparation: 3%; xylene solvent: 16%.

[0051] The following is a further description of the composition of the above components:

[0052] Saturated carboxylated polyester: solid content is 65%, specific gravity is 2.54, acid value is 22mgKOH / g.

[0053] Filler: including phosphate glass powder, chromium oxide, china clay, aluminum powder and talcum powder, by weight percentage, the filler includes: 28% phosphate glass powder, 2% chromium oxide, 3% china clay, 6% aluminum po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com