Spiral inner-tube vacuum heat collecting tube suitable for large temperature difference

A vacuum heat collector tube and spiral technology, applied in the field of solar energy utilization, can solve the problems of reducing solar radiation absorption, inconvenient for a large number of layouts, limited layout area, etc., and achieve the effects of high thermal efficiency, excellent compatibility and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

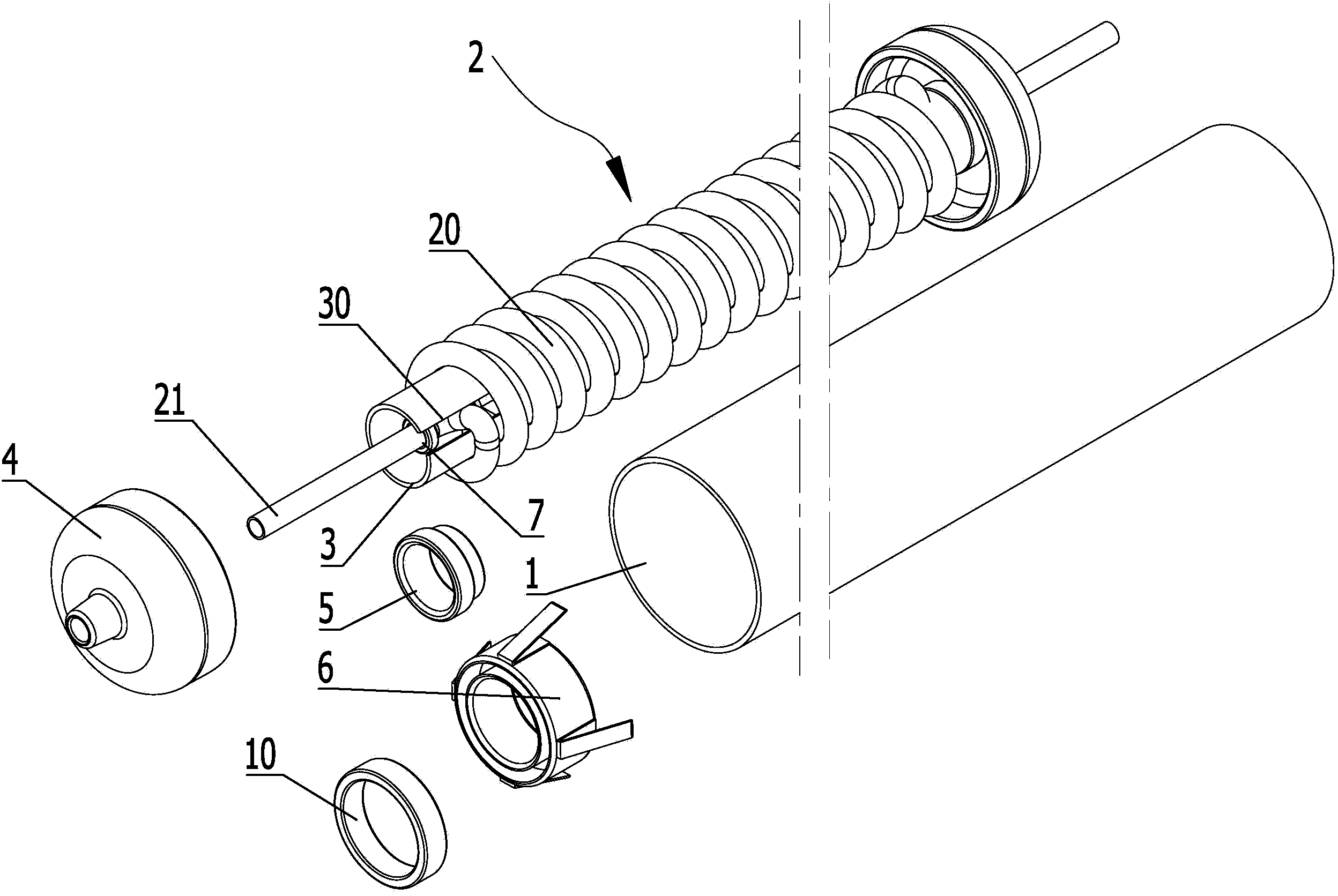

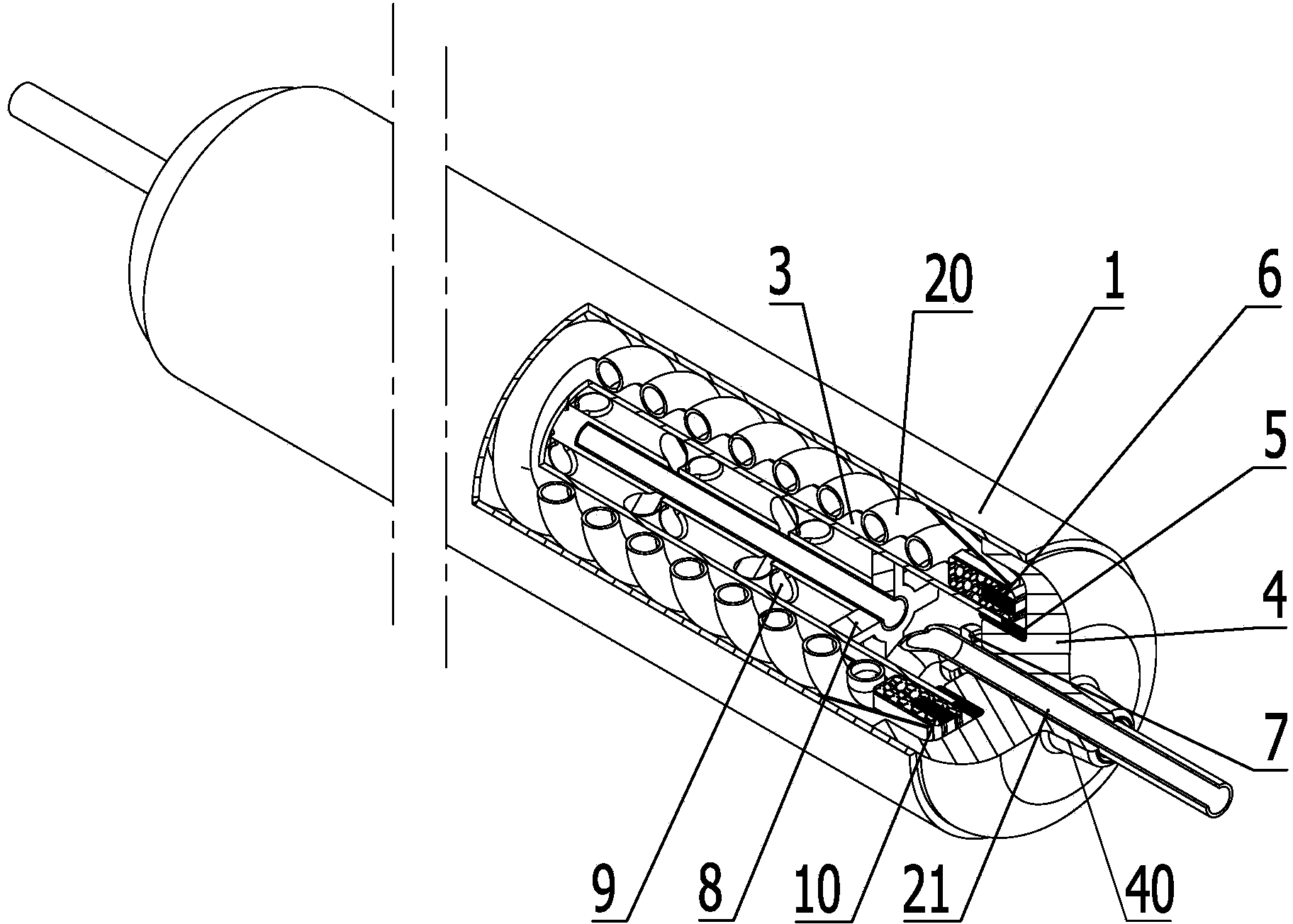

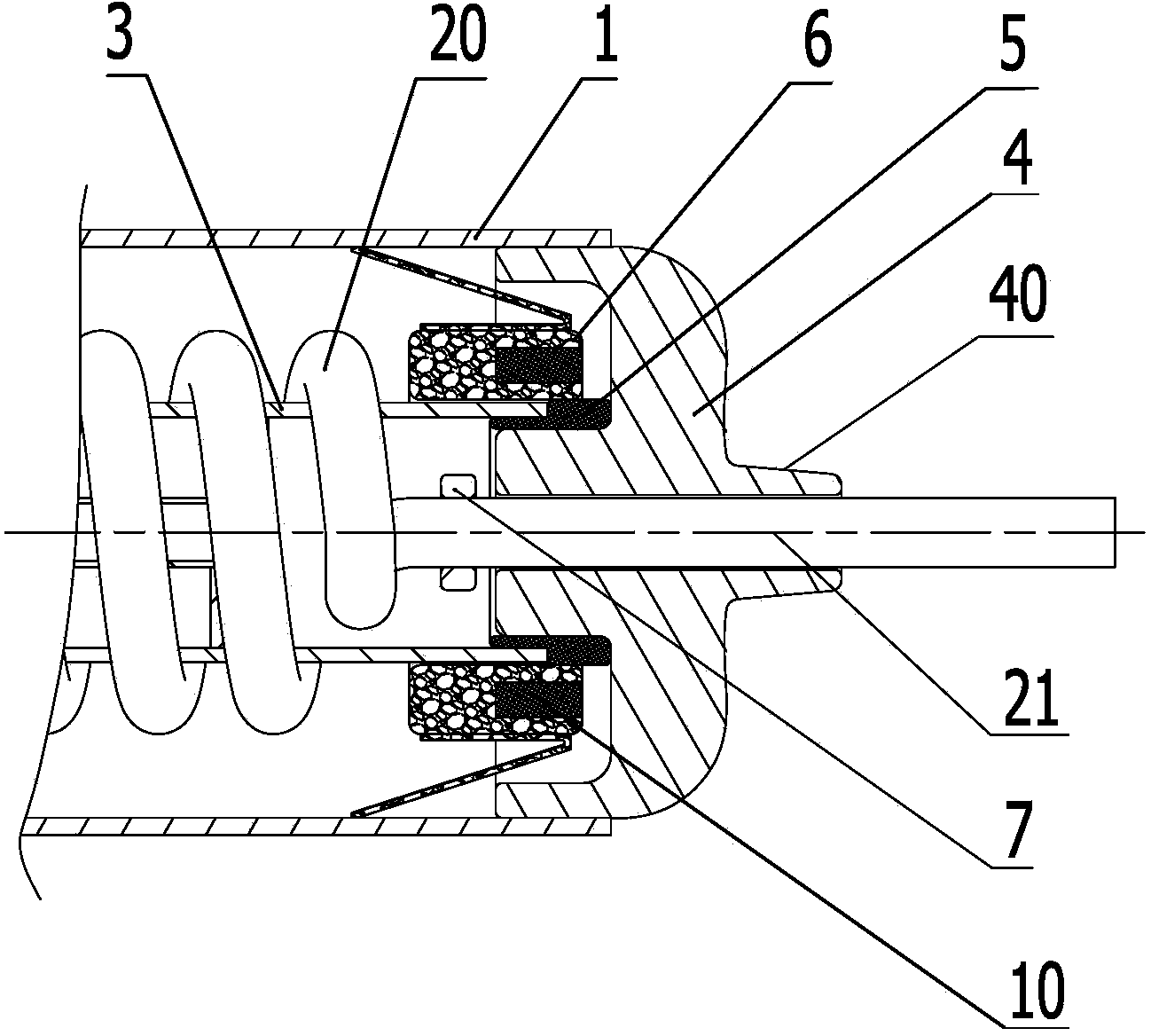

[0033] like figure 1 , 2 , 3 shows a spiral inner tube vacuum heat collector suitable for large temperature differences, including an outer tube 1, an inner tube 2, a support tube 3 and a sealing member. in:

[0034] The material of the outer tube 1 is any highly transparent material, which has a high transmittance to solar radiation with a wavelength of 0.3-3 microns. The present embodiment takes a glass outer tube as an example. Its specifications are outer diameter: 105mm, wall thickness: 3mm.

[0035] The inner tube 2 is a glass inner tube, and the outer tube wall of the inner tube 1 is covered with a heat-absorbing film. The inner tube 2 includes a spiral section 20 in the middle and a straight section 21 at both ends. Its specification outer diameter: 12mm, wall thickness: 1.2mm, lead: 13mm; main pipe length 1980mm, outer diameter of threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com