Lithium battery case flame-retardant material based on long-glass-fiber-reinforced polypropylene and preparation method thereof

A technology of flame-retardant materials and polypropylene, which is applied in the field of flame-retardant materials for lithium battery shells based on long glass fiber reinforced polypropylene and its preparation, can solve problems such as thermal safety hazards, and achieve safety assurance, strong practicability, and impact good toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

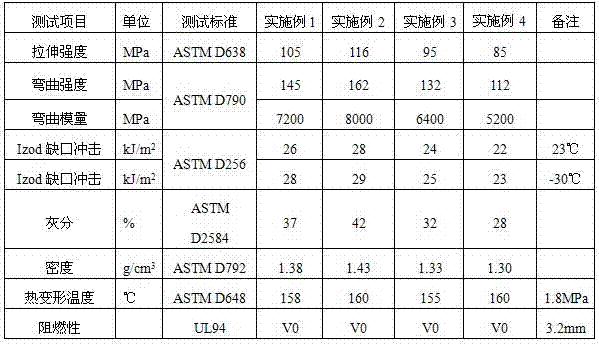

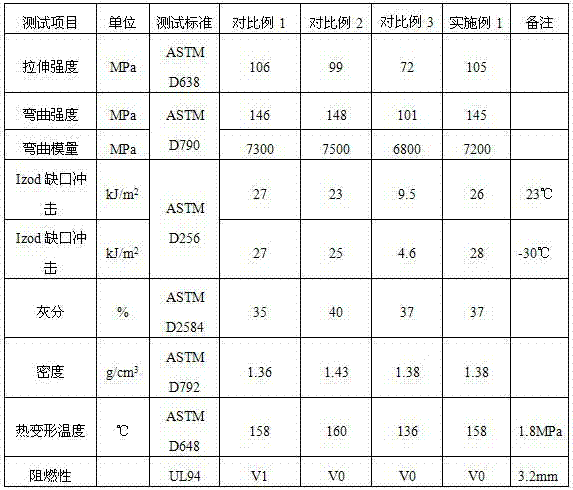

Embodiment 1

[0034] 1. The flame retardant material for lithium battery case based on long glass fiber reinforced polypropylene is prepared from the following components by weight: polypropylene: 35 parts, continuous glass fiber: 35 parts, coupling agent: 0.25 parts, Primary antioxidant: 0.05 parts, auxiliary antioxidant: 0.05 parts, lubricant: 0.8 parts, compatibilizer: 4.0 parts, composite flame retardant: 24 parts, black masterbatch: 1.0 parts;

[0035] Among them, polypropylene is high-melting block copolymerized polypropylene, its comonomer is ethylene, vinyl content is 2-4mol%, and the melt flow rate of high-melting block copolymerized polypropylene is 115g / 10min (test conditions : temperature 230°C, load 2.16Kg); the continuous glass fiber is continuous non-alkali glass fiber, the fiber diameter is 22μm, and the linear density is 1200tex; the coupling agent is γ-aminopropyltriethoxysilane; the main antioxidant is selected Tetrakis[methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl)propiona...

Embodiment 2

[0043] 1. The flame retardant material for lithium battery case based on long glass fiber reinforced polypropylene is prepared from the following components in parts by weight: polypropylene: 30 parts, continuous glass fiber: 40 parts, coupling agent: 0.1 parts, Primary antioxidant: 0.01 parts, auxiliary antioxidant: 0.1 parts, lubricant: 0.5 parts, compatibilizer: 3.5 parts, composite flame retardant: 28 parts, black masterbatch: 0.5 parts;

[0044] Among them, polypropylene is high-melting block copolymerized polypropylene, its comonomer is ethylene, vinyl content is 2-4mol%, and the melt flow rate of high-melting block copolymerized polypropylene is 120g / 10min (test conditions : temperature 230°C, load 2.16Kg), the continuous glass fiber is continuous non-alkali glass fiber, the fiber diameter is 17μm, and the linear density is 2400tex; the coupling agent is γ-2,3 glycidoxy-propyltrimethoxy Silane; the main antioxidant is β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl pr...

Embodiment 3

[0052] 1. The flame retardant material for lithium battery case based on long glass fiber reinforced polypropylene is prepared from the following components in parts by weight: polypropylene: 40 parts, continuous glass fiber: 30 parts, coupling agent: 0.5 parts, Primary antioxidant: 0.1 part, auxiliary antioxidant: 0.01 part, lubricant: 1 part, compatibilizer: 4.2 parts, composite flame retardant: 20 parts, black masterbatch: 1.0 part;

[0053] Among them, polypropylene is high-melting block copolymerized polypropylene, its comonomer is ethylene, vinyl content is 2-4mol%, and the melt flow rate of high-melting block copolymerized polypropylene is 130g / 10min (test conditions : temperature 230°C, load 2.16Kg), the continuous glass fiber is made of continuous non-alkali glass fiber, the fiber diameter is 10μm, and the linear density is 3600tex; the coupling agent is γ-aminopropyltriethoxysilane; the main antioxidant Use tetrakis[methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com