Preparation method of coating for heat-resistant steel plate

A steel plate, heat-resistant technology, used in anti-corrosion coatings, coatings, etc., can solve the problems of difficult large-area construction, poor metal adhesion, poor solvent resistance, etc., and achieve excellent adhesion and processability, heat resistance and heat resistance. The effect of better hardness and excellent solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

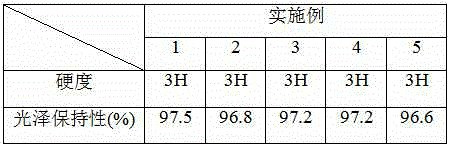

Examples

Embodiment 1

[0024] The coating that present embodiment relates to is made up of following components:

[0025] Silicone-modified polyester resin: It is prepared by polycondensation reaction of silicone resin with saturated polyester resin as a modifier, wherein the mass ratio of silicone resin to saturated polyester resin is 1:0.1, silicone The solid content of the modified polyester resin is 55%, the specific gravity is 1.08, and the acid value is 2mgKOH / g.

[0026] Pigment: including titanium dioxide and white carbon black, wherein the mass ratio of titanium dioxide and white carbon black is 1:1.

[0027] Filler: including barium sulfate, calcium carbonate, talc powder and silicon dioxide, wherein the mass ratio of barium sulfate, calcium carbonate, talc powder and silicon dioxide is 1:1.5:2:1.

[0028] Solvent: including butyl ether, butyl ester and butanol, the mass ratio of said butyl ether, butyl ester and butanol is 1:1:2.5.

[0029] Its preparation process is as follows:

[003...

Embodiment 2

[0037] The coating that present embodiment relates to is made up of following components:

[0038] Silicone-modified polyester resin: It is prepared by polycondensation reaction of silicone resin with saturated polyester resin as a modifier, wherein the mass ratio of silicone resin to saturated polyester resin is 1:0.4, silicone The solid content of the modified polyester resin is 65%, the specific gravity is 1.14, and the acid value is 10mgKOH / g.

[0039] Pigment: including titanium dioxide and white carbon black, wherein the mass ratio of titanium dioxide and white carbon black is 3:1.

[0040] Filler: including barium sulfate, calcium carbonate, talc powder and silicon dioxide, wherein the mass ratio of barium sulfate, calcium carbonate, talc powder and silicon dioxide is 2:3:4:1.

[0041] Solvent: including butyl ether, butyl ester and butanol, the mass ratio of butyl ether, butyl ester and butanol is 1.5:1:3.2.

[0042] Its preparation process is as follows:

[0043] A...

Embodiment 3

[0050] The coating that present embodiment relates to is made up of following components:

[0051] Silicone-modified polyester resin: It is prepared by polycondensation reaction of silicone resin with saturated polyester resin as a modifier, wherein the mass ratio of silicone resin to saturated polyester resin is 1:0.3, silicone The solid content of the modified polyester resin is 60%, the specific gravity is 1.11, and the acid value is 6mgKOH / g.

[0052] Pigment: including titanium dioxide and white carbon black, wherein the mass ratio of titanium dioxide and white carbon black is 2:1.

[0053] Filler: including barium sulfate, calcium carbonate, talc powder and silicon dioxide, wherein the mass ratio of barium sulfate, calcium carbonate, talc powder and silicon dioxide is 1.5:2:3:1.

[0054] Solvent: including butyl ether, butyl ester and butanol, the mass ratio of butyl ether, butyl ester and butanol is 1.2:1:2.9.

[0055] Its preparation process is as follows:

[0056] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com