Quantum dot luminous compound for 3D (Three Dimensional) printing and preparation method thereof

A technology of quantum dot luminescence and 3D printing, which is applied in the direction of additive processing, etc., can solve problems such as changes in the emission spectrum of phosphors, limitations in the development of phosphors, and severe light scattering effects, and achieve good comprehensive printing performance, increased mechanical properties, The effect of high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

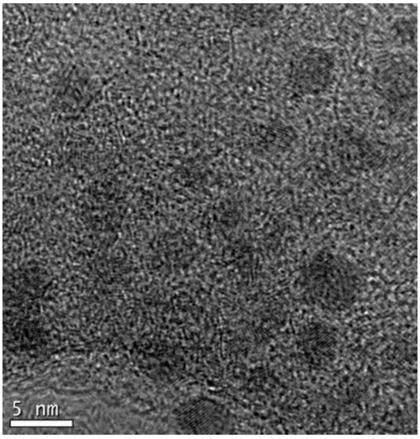

Image

Examples

Embodiment 1

[0027] A quantum dot luminescent compound for 3D printing, which consists of the following raw materials in parts by weight: 100 parts of polylactic acid, 0.2 parts of ADR 4370S, 5 parts of diethyl adipate monobutyl, 20 parts of nano-silica, 20 parts 1 part of graphene quantum dots, 1 part of nano calcium carbonate, 1 part of talcum powder.

[0028] The preparation method of the quantum dot luminescent compound for 3D printing is as follows: firstly, 20 parts of nano-silica and 20 parts of graphene quantum dots are mixed, and excess ethanol is added to the mixture, and then the mixed solution is dried at 60° C. for 8 hours, Obtain dried mixed powder;

[0029] After drying 100 parts of polylactic acid at 60°C for 4 hours, add polylactic acid and 0.2 parts of ADR 4370S into a high-speed mixer, stir at 10°C for 0.5h to fully mix at a speed of 200r / min, and then use a twin-screw mixer to extrude For granulation, the extrusion temperature is 175°C, the die head temperature is 160°...

Embodiment 2

[0032] A quantum dot light-emitting compound for 3D printing, which consists of the following raw materials in parts by weight: 100 parts of polylactic acid, 0.4 parts of ADR 4370S, 5 parts of diethyl adipate, 20 parts of nano-silica, 20 parts 1 part of graphene quantum dots, 1 part of nano calcium carbonate, 1 part of talcum powder.

[0033] The preparation method of the quantum dot luminescent compound for 3D printing is as follows: firstly, 20 parts of nano-silica and 20 parts of graphene quantum dots are mixed, and excess ethanol is added to the mixture, and then the mixed solution is dried at 70° C. for 9 hours, Obtain dried mixed powder;

[0034] After drying 100 parts of polylactic acid at 60°C for 4 hours, add polylactic acid and 0.4 parts of ADR 4370S into a high-speed mixer, stir at 20°C for 1 hour to fully mix at a speed of 300r / min, and then use a twin-screw mixer to extrude For granulation, the extrusion temperature is 180°C, the die head temperature is 180°C, th...

Embodiment 3

[0037] A quantum dot luminescent compound for 3D printing, which consists of the following raw materials in parts by weight: 100 parts of polylactic acid, 0.6 parts of ADR 4370S, 5 parts of diethyl monobutyl adipate, 20 parts of nano-silica, 20 parts 1 part of graphene quantum dots, 1 part of nano calcium carbonate, 1 part of talcum powder.

[0038] The preparation method of the quantum dot luminescent compound for 3D printing is as follows: firstly, 20 parts of nano-silica and 20 parts of graphene quantum dots are mixed, and excess ethanol is added to the mixture, and then the mixed solution is dried at 80° C. for 10 h, Obtain dried mixed powder;

[0039] After drying 100 parts of polylactic acid at 80°C for 5 hours, add polylactic acid and 0.6 parts of ADR 4370S into a high-speed mixer, stir at 30°C for 2 hours to fully mix at a speed of 300r / min, and then use a twin-screw mixer to extrude For granulation, the extrusion temperature is 185°C, the die head temperature is 180°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com