Polyphenylene sulfide composite material and preparation method thereof

A technology of polyphenylene sulfide and composite material, applied in the field of polyphenylene sulfide composite material and its preparation, can solve problems such as poor impact toughness, and achieve the effects of good performance, good mechanical performance and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

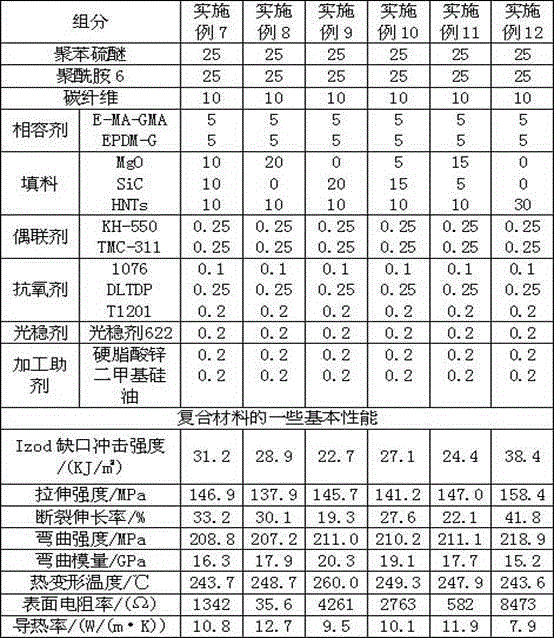

Examples

Embodiment 1-18

[0024] Embodiments 1-18 are as follows: All the following test items shall implement the corresponding national standards.

Embodiment 1

[0026] (1), first, 25 parts of polyphenylene sulfide (PPS), 25 parts of polyamide 66 (PA66), 5 parts of ethylene-methyl acrylate-glycidyl methacrylate copolymer (E-MA-GMA), 5 parts Add 0.25 parts of γ-(methacryloyloxy)propyl trimethoxysilane (KH-570), 0.25 parts of isopropyl tris(dioctyl pyrophosphate acyloxy) to 1 part of ethylene-vinyl acetate copolymer (EVA) ) Titanate (TMC-201) was mixed by a high-speed mixer for 3 minutes, the speed of the mixer was 180 rpm, and the mixing temperature was 60°C;

[0027] (2), then add 10 parts of magnesium oxide (MgO), 10 parts of aluminum oxide (Al 2 o 3 ), 10 parts of aluminum nitride (AlN), 0.1 part of N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionyl) hexamethylenediamine (anti-1098), 0.25 part dioctadecyl thiodipropionate (anti-DSTDP), 0.2 part N,N'-disalicylidene propylenediamine (T1201), 0.2 part 2-[4-[2-hydroxy-3- Tridecyloxypropyl]oxy]-2-hydroxyphenyl]-4,6-bis(2,4-dimethylphenyl)-1,3,5-triazine and 2-[4- [2-Hydroxy-3-...

Embodiment 2

[0030] (1) First, add 0.25 parts of KH-570 and 0.25 parts of TMC-201 to 25 parts of PPS, 25 parts of PA66, 5 parts of E-MA-GMA, and 5 parts of EVA and mix them for 3 minutes in a high-speed mixer with a speed of 180 rpm / min, the mixing temperature is 60°C;

[0031] (2), then add 20 parts of MgO, 10 parts of AlN, 0.1 parts of anti-1098, 0.25 parts of anti-DSTDP, 0.2 parts of T1201, 0.2 parts of UV-400, 0.2 parts of silicone powder, 0.2 parts of zinc stearate and continue mixing at high speed 3min, the speed of the mixer is 180 rpm, and the mixing temperature is 60°C;

[0032] (3) Extrude the mixed materials into granules through the extruder. When the extruder is extruded, 10 parts of carbon fiber are separately introduced from the glass fiber port of the extruder for mixed extrusion. The temperature of each zone of the extruder starts from the feeding The temperature from the material section to the head is 220°C, 240°C, 280°C, 285°C, 285°C, 290°C, 290°C, 295°C, 295°C, 300°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com