Flame retardant thermoplastic resin composition and mould product produced therefrom

A thermoplastic resin and composition technology, applied in the field of flame retardant thermoplastic resin composition, can solve problems such as molding equipment and mold corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

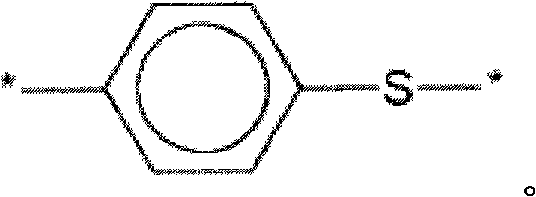

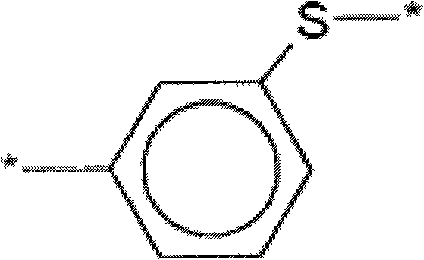

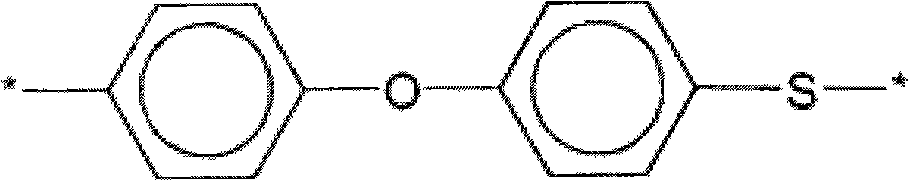

Method used

Image

Examples

Embodiment 1~7 and comparative example 1~7

[0174] The resin compositions according to Examples 1 to 7 and Comparative Examples 1 to 7 were prepared by using the compositions as in Tables 1 to 3 below using the aforementioned ingredients.

[0175] The resin composition was prepared by a manufacturing method in which various ingredients according to the compositions in Tables 1 to 3 below were mixed in a general mixer, and the mixture was placed in a twin-screw extruder. The mixture was made into a granular resin composition by an extruder. Then, the composition was made into a sample for performance evaluation by using a 10 oz molding apparatus at 330°C.

experiment example

[0177] The samples were kept in 50% relative humidity at 23° C. for 48 hours, and then the relevant properties were measured according to ASTM standards. The relative flexural strength and flexural modulus were determined on molded samples according to ASTM D790, and the relative notched Izod impact strength (1 / 8") was determined according to ASTM D256.

[0178] According to the standard of ASTM D-648, the relative heat resistance is evaluated for 1 / 4 inch (6.4mm) thick samples by placing them in oil heated at a rate of 120°C / hour, then pressurized at 1.86MPa and The temperature at which it was bent to about 0.254 mm was measured.

[0179] The flame retardancy at a thickness of 0.8 mm was determined according to the UL 94VB flame retardancy standard.

[0180] Gas evolution was measured by measuring weight loss by heating the sample from 30°C to 320°C at a heating rate of 20°C / min using TGA (TA Instruments, TGA Q5000), and then maintaining at 320°C for 30 minutes.

[0181] [T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com