Method for generating denitration catalyst on filter material in situ

A denitrification catalyst and in-situ generation technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of small quantity, damage to the molecular structure and physical properties of polyphenylene sulfide fibers, etc., and achieve basic There is no material type and shape, no special requirements, no pollution, and the effect of saving treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

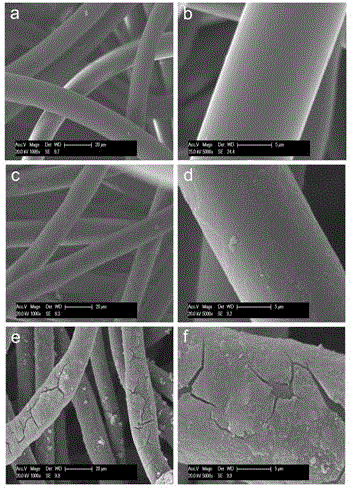

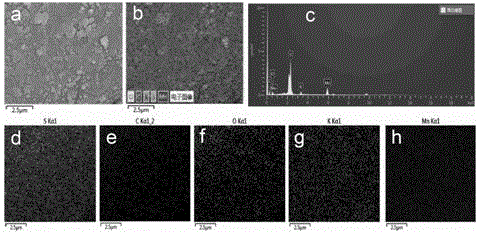

[0029] Add 0.6g of dopamine hydrochloride powder into 300mL of deionized water to prepare a 2g / L dopamine solution, and add 0.36g of tris(hydroxymethyl)aminomethane to adjust the pH of the solution to 8.5, and then add polyphenylene sulfide Immerse the ether filter material in the above solution, stir at room temperature for 24 hours, take it out, wash it with water and ethanol, and dry it in a vacuum oven at 80°C to constant weight to prepare a dopamine-modified polyphenylene sulfide filter material;

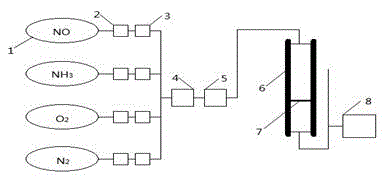

[0030] Immerse the dopamine-modified polyphenylene sulfide filter material in 0.05M manganese acetate solution, take it out after standing for 1h, rinse off the residual solution with deionized water, and then immerse it in 0.05M potassium permanganate solution for 3h to make In situ generation of MnO on the surface of the filter material 2 Catalyst, finally take out the filter material, wash it with water and ethanol, and dry it to constant weight in a vacuum oven at 80°C to o...

Embodiment 2

[0033] Add 0.9g of dopamine hydrochloride powder into 300mL of deionized water to prepare a 3g / L dopamine solution, and add 0.36g of tris(hydroxymethyl)aminomethane to adjust the pH of the solution to 8.5, and then the polyphenylene sulfide Immerse the ether filter material in the above solution, stir at room temperature for 30 hours, take it out, wash it with water and ethanol, and dry it in a vacuum oven at 80°C to constant weight to prepare a dopamine-modified polyphenylene sulfide filter material;

[0034] Immerse the dopamine-modified polyphenylene sulfide filter material in 0.03M manganese acetate solution, take it out after standing for 2 hours, rinse off the residual solution with deionized water, and then immerse it in 0.06M potassium permanganate solution for 4 hours to make In situ generation of MnO on the surface of the filter material 2 Catalyst, finally take out the filter material, wash it with water and ethanol, and dry it to constant weight in a vacuum oven at...

Embodiment 3

[0037] Add 0.3g of dopamine hydrochloride powder into 300mL of deionized water to prepare a 1g / L dopamine solution, and add 0.4g of tris(hydroxymethyl)aminomethane to it to adjust the pH of the solution to 9, and then the polyphenylene sulfide Immerse the ether filter material in the above solution, stir at room temperature for 18 hours, take it out, wash it with water and ethanol, and dry it in a vacuum oven at 50°C to constant weight to prepare a dopamine-modified polyphenylene sulfide filter material;

[0038] Immerse the dopamine-modified polyphenylene sulfide filter material in a 0.01M manganese acetate solution, take it out after standing for 4 hours, rinse off the residual solution with deionized water, and then immerse it in a 0.03M potassium permanganate solution for 8 hours to make In situ generation of MnO on the surface of the filter material 2 Catalyst, finally take out the filter material, wash it with water and ethanol and dry it to constant weight in a vacuum o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com