Modification-enhanced polyether ether ketone material and preparation method thereof

A polyether ether ketone and modification technology, which is applied in the field of modified and enhanced polyether ether ketone materials and their preparation, can solve the problems of lack of modification technology, limitation of modification technology and high processing temperature, and achieve good economic benefits , the preparation process is simple, the effect of reducing the processing temperature and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

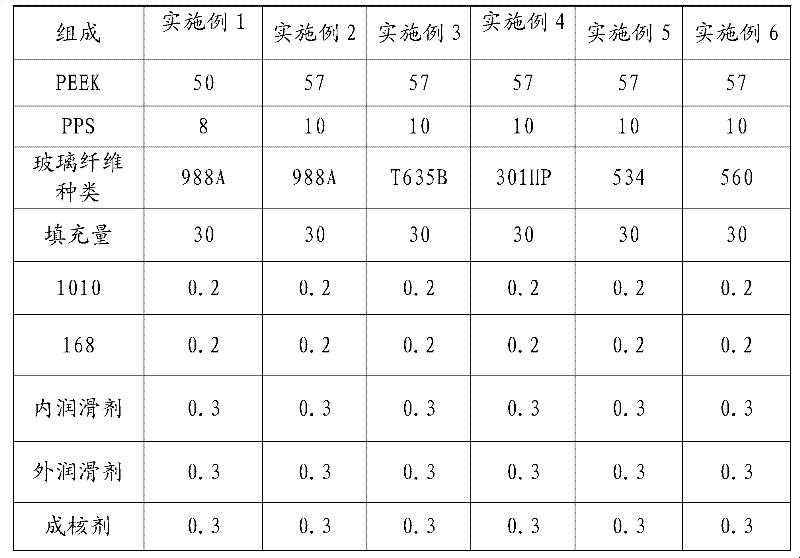

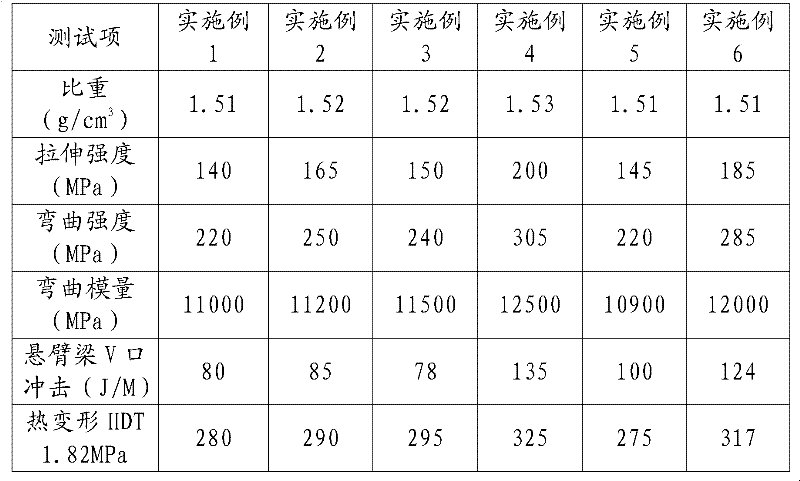

Embodiment 1

[0043] Weigh 50 parts of polyether ether ketone (PEEK), 8 parts of polyphenylene sulfide (PPS), 30 parts of long glass fiber 988A, 0.2 parts of antioxidants 1010 and 168, lubricant TAF and silicone Alkanes are 0.3 parts, and nucleating agent CAV102 is 0.3 parts.

[0044] Composite materials were prepared by the following methods:

[0045] a. Dry polyether ether ketone (140°C 3h) and polyphenylene sulfide (120°C 4h);

[0046] b. Add the dried polyether ether ketone and polyphenylene sulfide to the high-speed mixer, and add lubricant, nucleating agent and antioxidant, and mix at high speed for about 4 minutes;

[0047] c. Put the mixed raw materials and additives into the twin-screw extruder, add glass fiber to carry out reinforcement filling extrusion granulation.

[0048] The temperature setting of each section of the twin-screw extruder is: the temperature of the first zone is 250°C, the temperature of the second zone is 330°C, the temperature of the third zone is 330°C, th...

Embodiment 2

[0050] Weigh 57 parts of polyether ether ketone (PEEK), 10 parts of polyphenylene sulfide (PPS), 30 parts of long glass fiber 988A, 0.2 parts of antioxidants 1010 and 168, lubricant TAF and silicone Alkanes are 0.3 parts, and nucleating agent CAV102 is 0.3 parts.

[0051] Composite materials were prepared by the following methods:

[0052] a. Dry polyether ether ketone (150°C 3h) and polyphenylene sulfide (140°C 4h);

[0053] b. Add the dried polyether ether ketone and polyphenylene sulfide to the high-speed mixer, and add lubricant, nucleating agent and antioxidant, and mix at high speed for about 4 minutes;

[0054] c. Put the mixed raw materials and additives into the twin-screw extruder, add glass fiber to carry out reinforcement filling extrusion granulation.

[0055] The temperature setting of each section of the twin-screw extruder is: the temperature of the first zone is 260°C, the temperature of the second zone is 330°C, the temperature of the third zone is 340°C, t...

Embodiment 3

[0057] Weigh 57 parts of polyether ether ketone (PEEK), 10 parts of polyphenylene sulfide (PPS), 30 parts of long glass fiber T635B, 0.2 parts of antioxidant 1010 and 168, lubricant TAF and silicone Alkanes are 0.3 parts, and nucleating agent CAV102 is 0.3 parts.

[0058] Composite materials were prepared by the following methods:

[0059] a. Dry polyether ether ketone (150°C 3h) and polyphenylene sulfide (140°C 4h);

[0060] b. Add the dried polyether ether ketone and polyphenylene sulfide to the high-speed mixer, and add lubricant, nucleating agent and antioxidant, and mix at high speed for about 4 minutes;

[0061] c. Put the mixed raw materials and additives into the twin-screw extruder, add glass fiber to carry out reinforcement filling extrusion granulation.

[0062] The temperature setting of each section of the twin-screw extruder is: the temperature of the first zone is 250°C, the temperature of the second zone is 330°C, the temperature of the third zone is 330°C, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com