Three-dimensional dbc ceramic circuit board manufacturing method and prepared three-dimensional dbc ceramic circuit board

A manufacturing method and circuit board technology, which can be used in chemical/electrolytic methods to remove conductive materials, printed circuit components, etc., can solve the problems of copper plate etching, poor depth control, poor fluidity of photosensitive dry film, etc. High controllability and smooth hole sides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

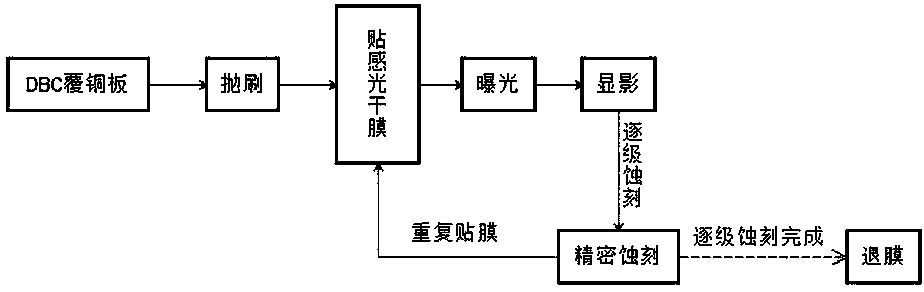

[0041] A method for manufacturing a three-dimensional DBC ceramic circuit board with double reference planes, the steps comprising:

[0042] a. Polish and micro-etch the surface of the DBC copper-clad laminate covered with 0.3mm thick copper to roughen the surface so that it has enough contact area with the photosensitive dry film to increase the bonding force;

[0043] b. Paste photosensitive dry film on the surface of DBC copper clad board in the yellow light room. The film temperature is 115°C, the film pressure is 0.46MP, and the film speed is 0.9m / min. Let it stand for 15 minutes to prevent the photosensitive dry film from thermal expansion and contraction, which will change the size of the exposed pattern. ;

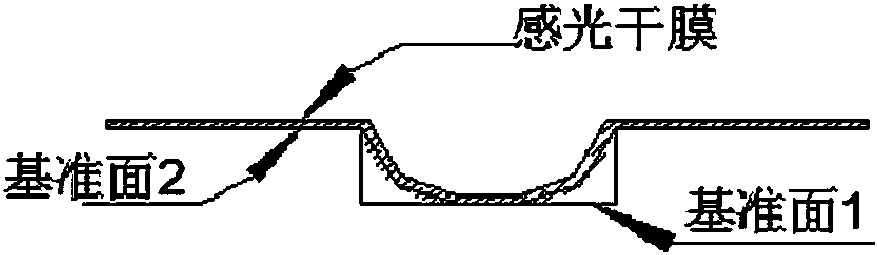

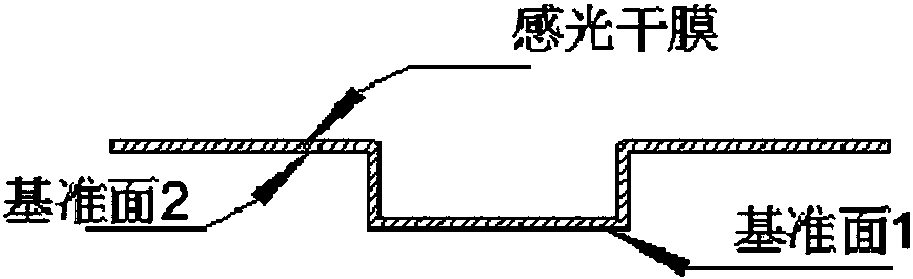

[0044] c. Will be as Figure 6 The shown film 1 with holes is correctly placed on the surface of the DBC copper-clad board pasted with the photosensitive film and covered with the exposure worktable cover to vacuumize, the vacuum degree is -0.06MP, and the exposur...

Embodiment 2

[0049] The three-dimensional DBC ceramic circuit board manufacturing method of three reference planes, the steps include:

[0050] a. Polish and micro-etch the surface of the DBC copper-clad laminate covered with 0.3mm thick copper to roughen the surface so that it has enough contact area with the photosensitive dry film to increase the bonding force;

[0051] b. Paste photosensitive dry film on the surface of DBC copper-clad board in the yellow light room. The film temperature is 115°C, the film pressure is 0.46MP, and the film speed is 0.8m / min. Let stand for 30 minutes to prevent the photosensitive dry film from thermal expansion and contraction, which will change the size of the exposed pattern. ;

[0052] c. will be as Figure 9 The shown film 1 with holes is correctly placed on the surface of the DBC copper-clad board pasted with the photosensitive film, and the cover plate of the exposure table is vacuumed, the vacuum degree is -0.07MP, and the exposure energy is 23 gr...

Embodiment 3

[0059] A three-dimensional DBC ceramic circuit board manufacturing method with four reference planes, the steps comprising:

[0060] a. Polish and micro-etch the surface of the DBC copper-clad laminate covered with 0.3mm thick copper to roughen the surface so that it has enough contact area with the photosensitive dry film to increase the bonding force;

[0061] b. Paste photosensitive dry film on the surface of DBC copper clad board in the yellow light room. The film temperature is 115°C, the film pressure is 0.46MP, and the film speed is 1.1m / min. Let stand for 25 minutes to prevent the photosensitive dry film from thermal expansion and contraction, which will change the size of the exposed pattern. ;

[0062] c. will be as Figure 9 The shown film 1 with holes is correctly placed on the surface of the DBC copper-clad board pasted with the photosensitive film and covered with the exposure table cover to vacuumize, the vacuum degree is -0.09MP, and the exposure energy is 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com