Hydraulic movable dam operating system

A technology of operating system and hydraulic system, which is applied in water conservancy projects, sea area projects, coastline protection, etc., and can solve problems such as short life, high maintenance costs, and manual cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

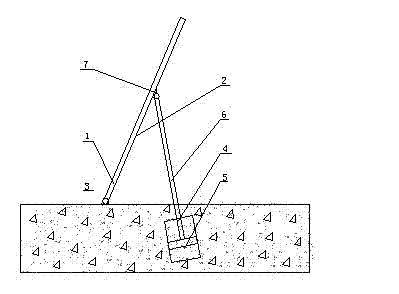

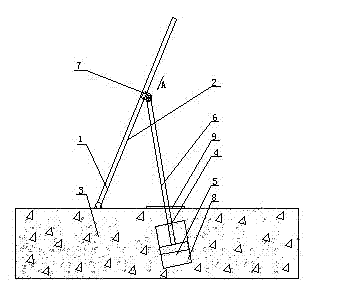

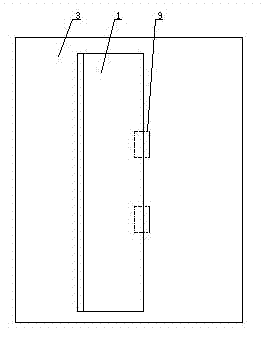

[0025] figure 1 , figure 2 , image 3 with Figure 4 The hydraulic movable dam operation system shown includes dam surface 1, dam surface backwater surface 2, horizontal foundation 3, main hydraulic system 4, hydraulic cylinder 5, hydraulic cylinder extension rod 6, lug structure 7, hydraulic cylinder body 8, Steel plate glue sealing structure 9, spherical structure 10, through hole 11, assembly hole 12, pin shaft 13, spherical groove 14, axial locking hole 15, small pin shaft 16.

[0026] The hydraulic movable dam operating system of the present invention mainly includes: a dam surface 1 and a main hydraulic system 4. When setting the dam surface, ensure that the back water surface of the dam surface forms an acute angle with the horizontal foundation, and its bottom edge is hinged on the support column on the horizontal foundation. The main hydraulic system 4 is mainly a hydraulic cylinder 5 and a hydraulic circuit arranged on the horizontal foundation 3 of the backwate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com