Wear-resistant and high-toughness polyphenylene sulfide composite material and preparation method thereof

A polyphenylene sulfide and composite material technology, which is applied in the field of polymer material modification, can solve the problems of easy generation of creep, poor toughness of polyphenylene sulfide, unsuitable impact modification, etc., so as to improve wear resistance and application The effect of broad field and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

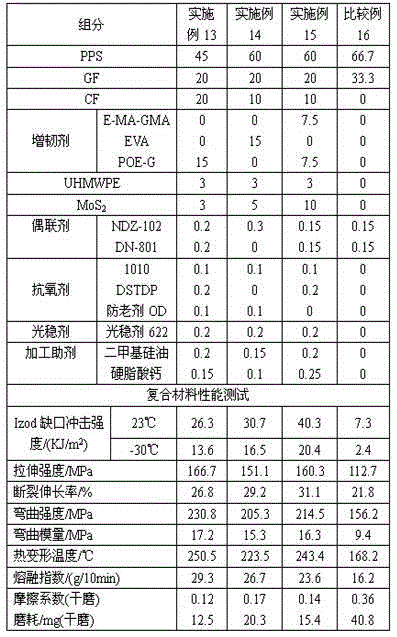

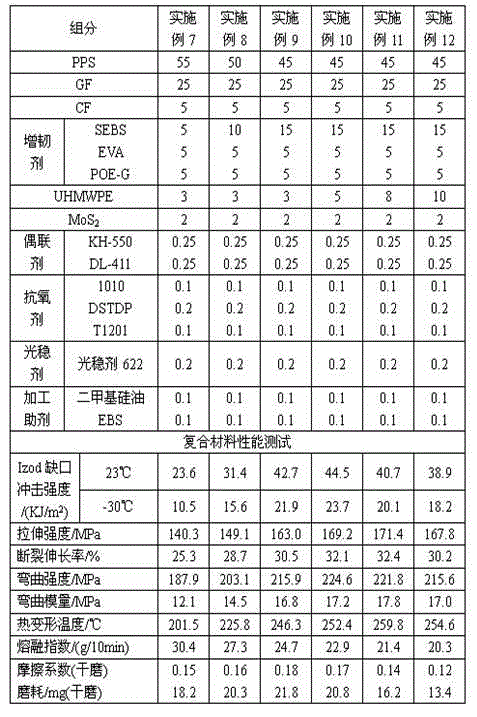

[0031] Add 0.25 parts of KH-550, 0.25 parts of NDZ-201 and 0.1 parts of simethicone to 55 parts of PPS, 5 parts of E-MA-GMA, 5 parts of E-nBA and 5 parts of EPDM-G and mix by high-speed mixer 3min, then add 3 parts of PTFE powder, 2 parts of MoS 2 , 0.1 part of anti-1010, 0.2 part of anti-168, 0.1 part of T1201, 0.2 part of UV-400, 0.1 part of silicone mixed at high speed for 3 minutes, 25 parts of GF and 5 parts of CF were simultaneously introduced from the glass fiber port, and the mixed material was extruded Extrusion extrusion granulation, the temperature of each zone of the extruder from the feeding section to the head temperature is 200°C, 220°C, 270°C, 290°C, 290°C, 290°C, 300°C, 300°C, 305°C, 305°C, the length-to-diameter ratio of the extrusion screw is 35, the rotation speed of the extrusion screw is 180 rpm, and the feeding speed is 30 rpm. The component distribution ratio and basic properties are shown in Table 1.

[0032]

Embodiment 2

[0034] Add 0.25 parts of KH-550, 0.25 parts of NDZ-201, and 0.1 parts of simethicone to 50 parts of PPS, 10 parts of E-MA-GMA, 5 parts of E-nBA, and 5 parts of EPDM-G and mix them for 3 minutes in a high-speed mixer , then add 3 parts of PTFE powder, 2 parts of MoS 2 , 0.1 part of anti-1010, 0.2 part of anti-168, 0.1 part of T1201, 0.2 part of UV-400, 0.1 part of silicone mixed at high speed for 3 minutes, extruding the mixed material through an extruder to granulate, 25 parts of GF and 5 parts of CF Introduced at the same time by the glass fiber port, the temperature of each zone of the extruder from the feeding section to the die head is 200°C, 220°C, 270°C, 290°C, 290°C, 290°C, 300°C, 300°C, 305°C, 305°C, the length-to-diameter ratio of the extrusion screw is 35, the rotation speed of the extrusion screw is 180 rpm, and the feeding speed is 27 rpm. The component distribution ratio and basic properties are shown in Table 1.

Embodiment 3

[0036] Add 0.25 parts of KH-550, 0.25 parts of NDZ-201, and 0.1 parts of simethicone to 45 parts of PPS, 15 parts of E-MA-GMA, 5 parts of E-nBA, and 5 parts of EPDM-G and mix them for 3 minutes in a high-speed mixer , then add 3 parts of PTFE powder, 2 parts of MoS 2 , 0.1 part of anti-1010, 0.2 part of anti-168, 0.1 part of T1201, 0.2 part of UV-400, 0.1 part of silicone mixed at high speed for 3 minutes, extruding the mixed material through an extruder to granulate, 25 parts of GF and 5 parts of CF Introduced at the same time by the glass fiber port, the temperature of each zone of the extruder from the feeding section to the die head is 200°C, 220°C, 270°C, 290°C, 290°C, 290°C, 300°C, 300°C, 305°C, 305°C, the length-to-diameter ratio of the extrusion screw is 35, the rotation speed of the extrusion screw is 180 rpm, and the feeding speed is 24 rpm. The component distribution ratio and basic properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com