Polyphenylene sulfide composite material and preparation method thereof

A technology of polyphenylene sulfide and composite materials, applied in the field of thermoplastic polymer materials, can solve problems such as not being able to meet the requirements of use, and achieve the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

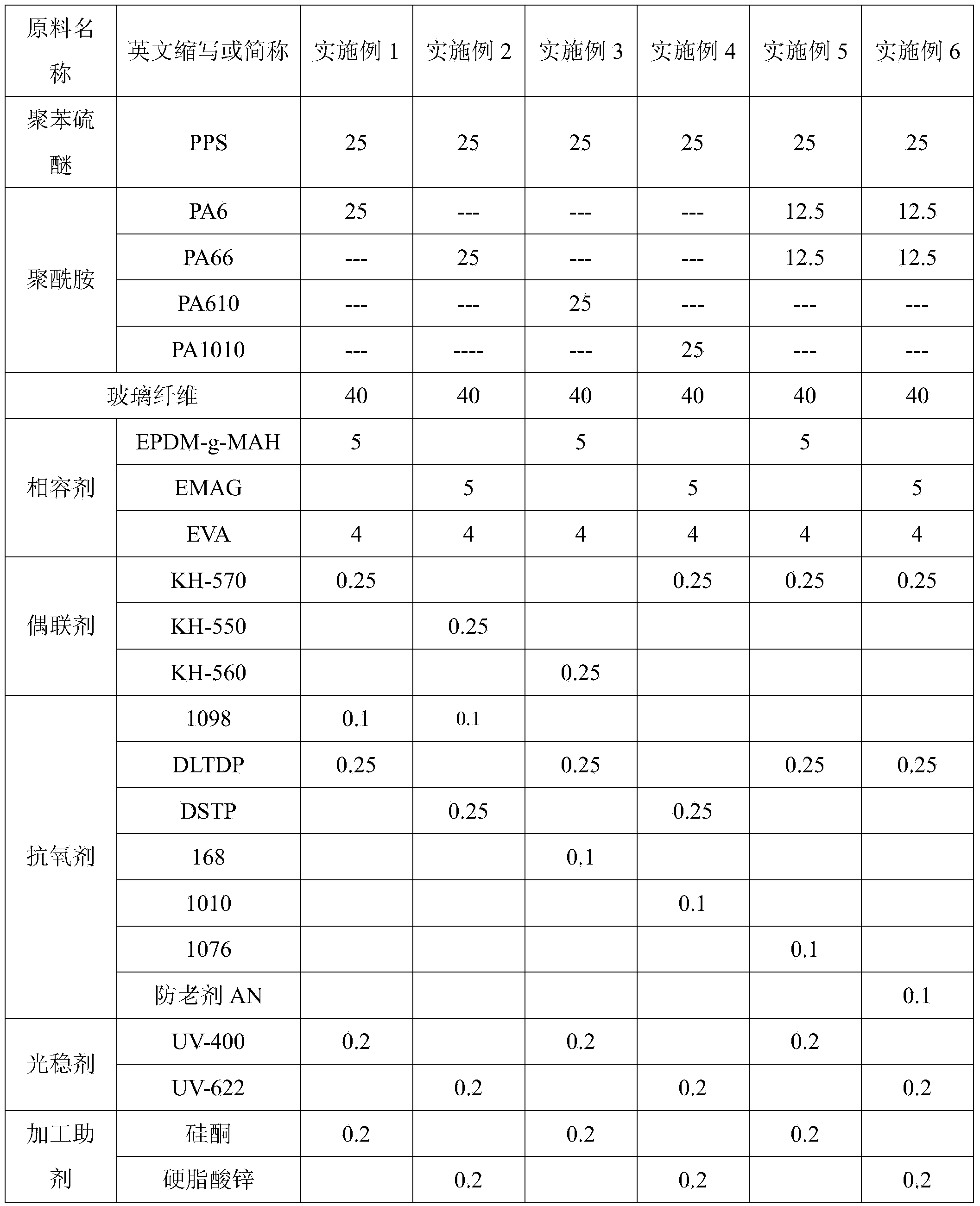

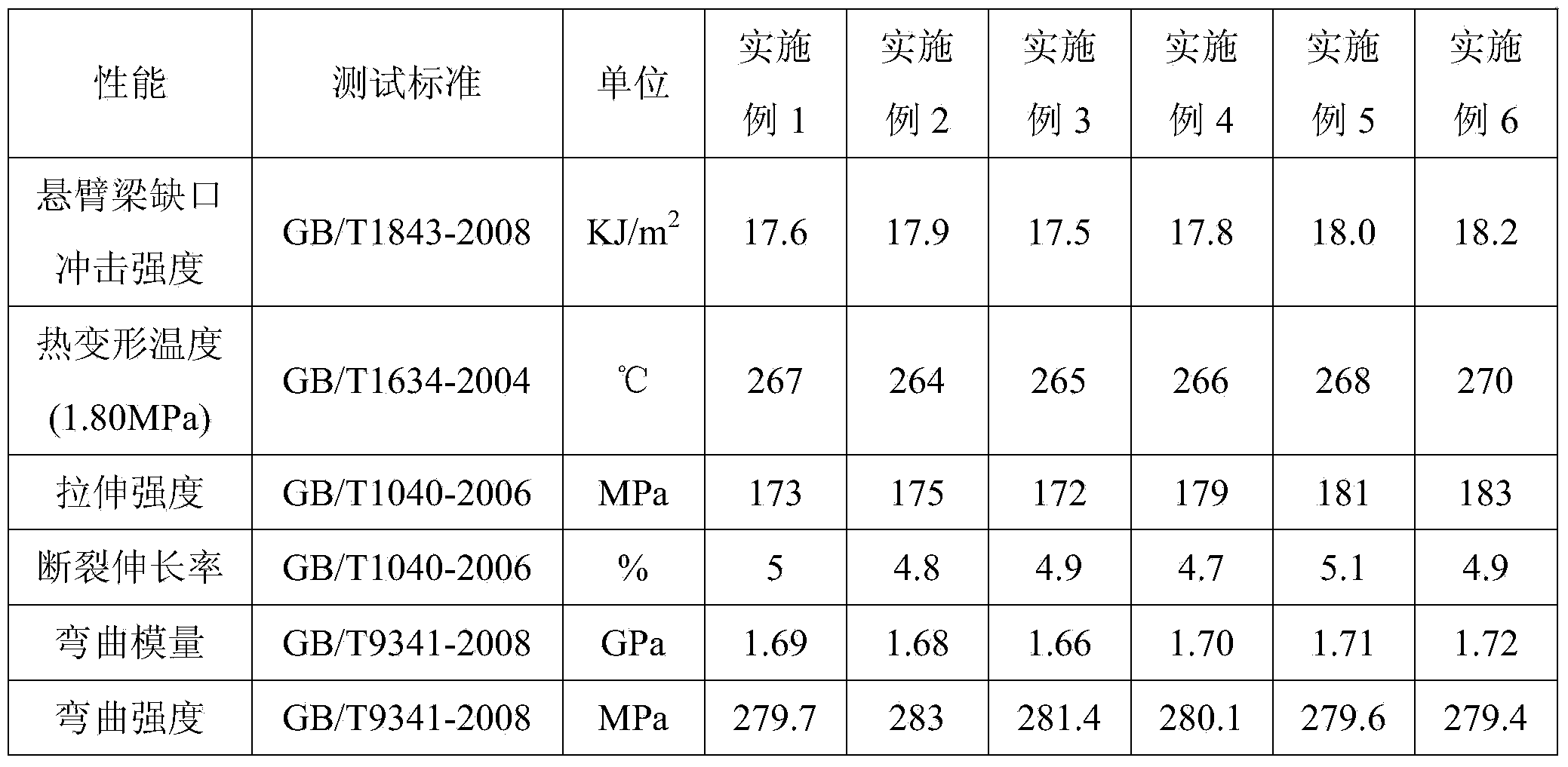

Embodiment 1

[0021] Embodiment 1: first by 25% polyphenylene sulfide (PPS), 25% polyamide 6 (PA6), 40% glass fiber, 5% ternary isopropyl rubber graft maleic anhydride (EPDM-g -MAH), 4% ethylene-vinyl acetate copolymer (EVA), 0.25% γ-(methacryloyloxy)propyltrimethoxysilane (KH-570), 0.1% N,N'-bis -(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine (Anti-1098), 0.25% dilauryl thiodipropionate (DLTDP), 0.2% 2-[4-[2-Hydroxy-3-tridecyloxypropyl]oxy]-2-hydroxyphenyl]-4,6-bis(2,4-dimethylphenyl)-1 ,3,5-triazine and 2-[4-[2-hydroxy-3-dodecyloxypropyl]oxy]-2-hydroxyphenyl]-4,6-bis(2,4-di Mixture of methylphenyl)-1,3,5-triazine (UV-400), 0.2% silicone powder by weight composition Prepare various raw materials; then add other raw materials except glass fiber to Disperse and mix in a high-speed mixer with a rotation speed of 600rpm, the mixing time is 3min, and the mixing temperature is 60°C; The head temperature is controlled at 240°C, 280°C, 300°C, 320°C, 320°C, 320°C, 320°C, 32...

Embodiment 2

[0022]Embodiment 2: first by 25% polyphenylene sulfide (PPS), 25% polyamide 66 (PA66), 40% glass fiber, 5% ternary isopropyl rubber graft maleic anhydride (EPDM-g -MAH), 4% ethylene-vinyl acetate copolymer (EVA), 0.25% 3-aminopropyltriethoxysilane (KH-550), 0.1% N,N'-bis-(3-( 3,5-di-tert-butyl-4-hydroxyphenyl) propionyl) hexamethylene diamine (anti-1098), 0.25% dioctadecyl thiodipropionate (anti-DSTP), 0.2% polybutylene Acid (4-hydroxyl-2,2,6,6-tetramethyl-1-piperidine ethanol) ester (UV-622), 0.2% zinc stearate composition by weight to prepare various raw materials; then Other raw materials except glass fibers are sequentially added into a high-speed mixer with a rotation speed of 400rpm to disperse and mix, the mixing time is 6min, and the mixing temperature is 50°C; after the mixing is completed, the mixed materials are put into the extruder, and the extrusion The temperature of each area of the machine is controlled at 240°C, 280°C, 300°C, 320°C, 320°C, 320°C, 320°C, 32...

Embodiment 3

[0023] Example 3: First, 25% polyphenylene sulfide (PPS), 25% polyamide 610 (PA610), 5% terpolymer grafted maleic anhydride (EPDM-g-MAH), 40% Glass fiber, 4% ethylene-vinyl acetate copolymer (EVA), 0.25% γ-(2,3-epoxypropoxy)propyltrimethoxysilane (KH-560), 0.1% tri( 2,4-di-tert-butylphenyl) phosphite (Anti-168), 0.25% didodecanol thiodipropionate (DLTDP), 0.2% 2-[4-[2-hydroxy-3 -tridecyloxypropyl]oxy]-2-hydroxyphenyl]-4,6-bis(2,4-dimethylphenyl)-1,3,5-triazine and 2-[4 -[2-Hydroxy-3-dodecyloxypropyl]oxy]-2-hydroxyphenyl]-4,6-bis(2,4-dimethylphenyl)-1,3,5- A mixture of triazine (UV-400) and 0.2% silicone powder by weight: Prepare various raw materials; then add other raw materials except glass fiber to a high-speed mixer with a speed of 380rpm to disperse and mix, and the mixing time The mixing temperature is 8 minutes, and the mixing temperature is 65°C; after the mixing is completed, put the mixed material into the extruder, and control the temperature of each zone of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com