Over-current over-voltage protective element and manufacture method thereof

A technology of overcurrent and overvoltage protection and components, which is applied in the direction of fuse manufacturing, electrical components, emergency protection devices, etc., can solve problems such as non-ideal protection methods, and achieve good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

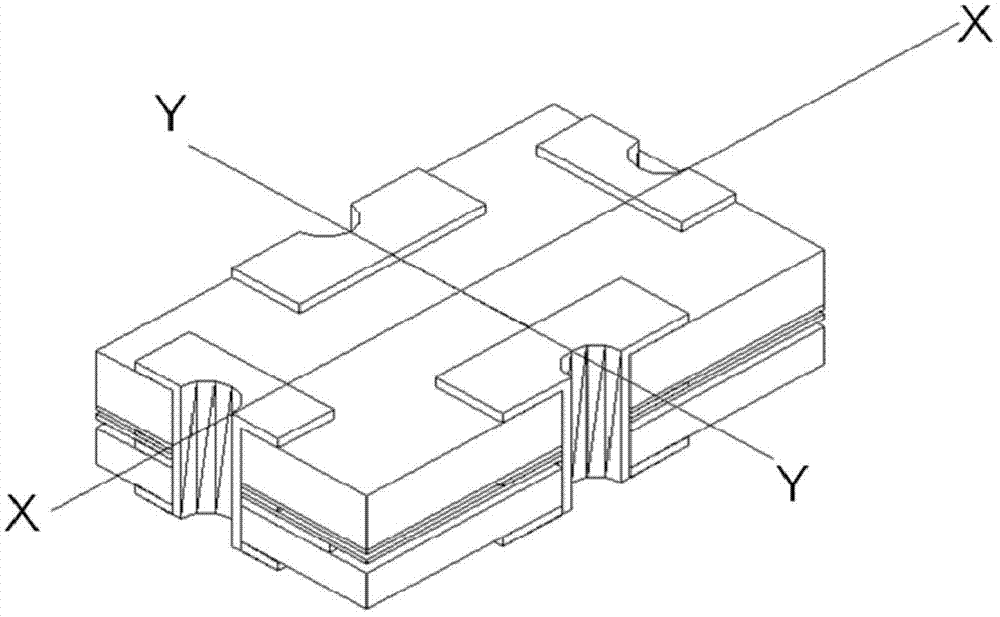

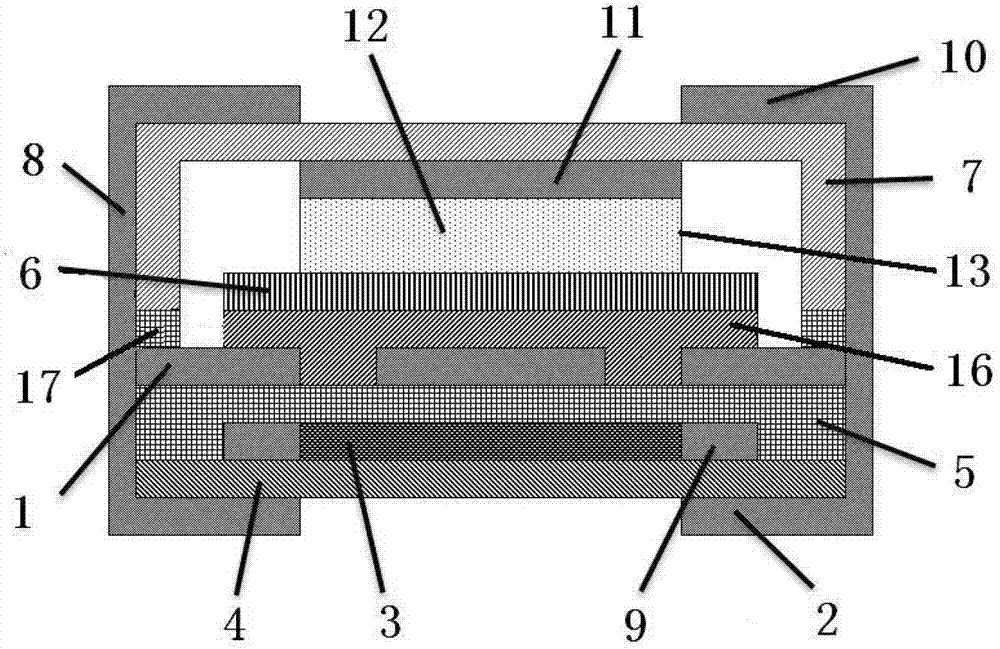

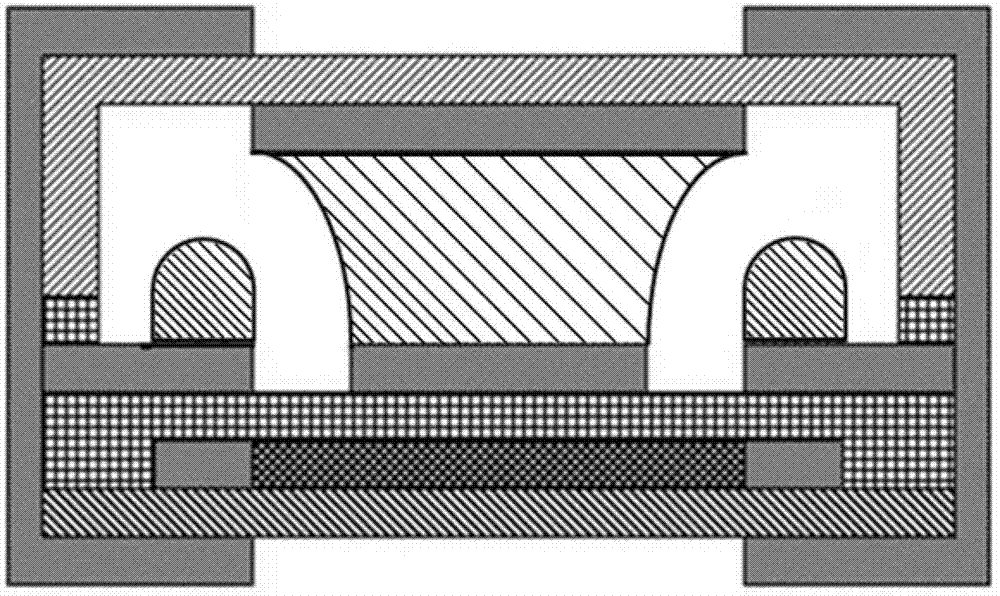

[0055]The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0056] An overcurrent and overvoltage protection element according to the present invention includes a bearing plate, a melt, an upper cover plate 7 and an end electrode 8:

[0057] The carrier plate includes a middle electrode 1, a lower electrode 2, a resistance layer 3, a first insulating layer 4, and a second insulating layer 5. The middle electrode 1 is divided into at least three isolated regions, and between the middle electrode 1 and the lower electrode 2 A resistive layer 3 and a resistive electrode 9 are provided, a first insulating layer 4 is provided between the lower electrode 2 and the resistive layer 3, and a second insulating layer 5 is provided between the middle electrode 1 and the resistive layer 3;

[0058] The melt covers the middle electrode 1, so that the isolated regions of the middle electrodes 1 form an electrical connection;

[0059...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com