Patents

Literature

33results about How to "Does not affect dielectric properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

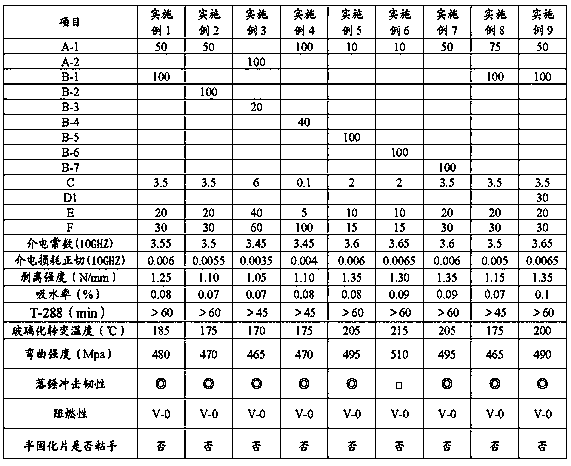

Thermosetting resin composition, and prepreg and laminated plate produced by using thermosetting resin composition

ActiveCN106243626AGood compatibilityImprove interface performanceSynthetic resin layered productsElectrical equipmentImideEpoxy

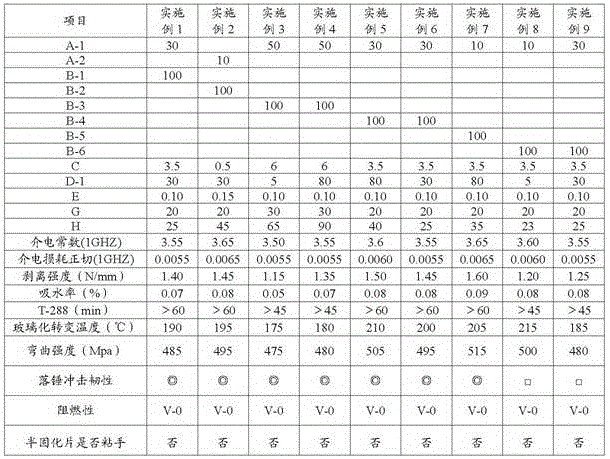

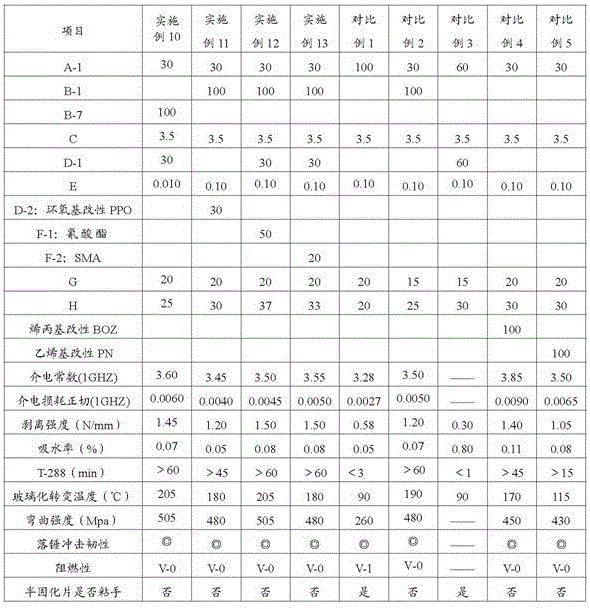

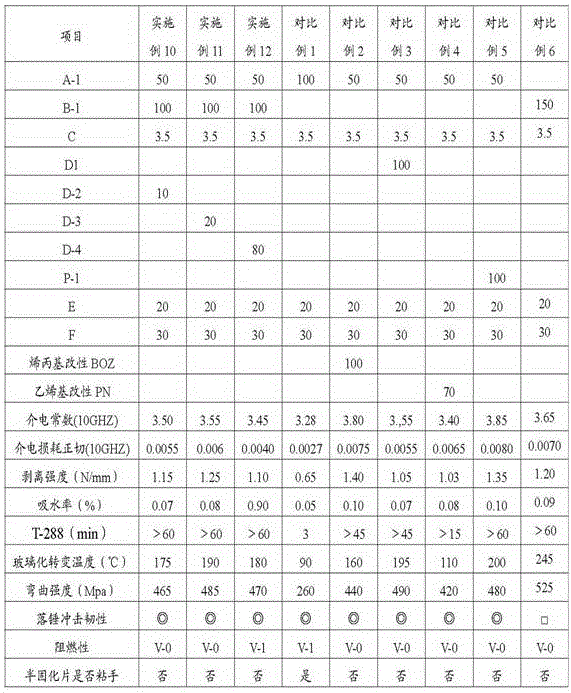

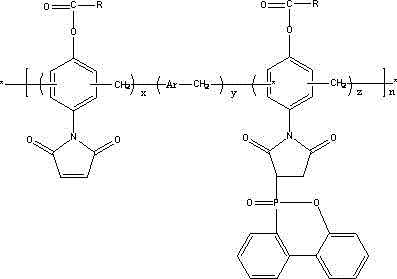

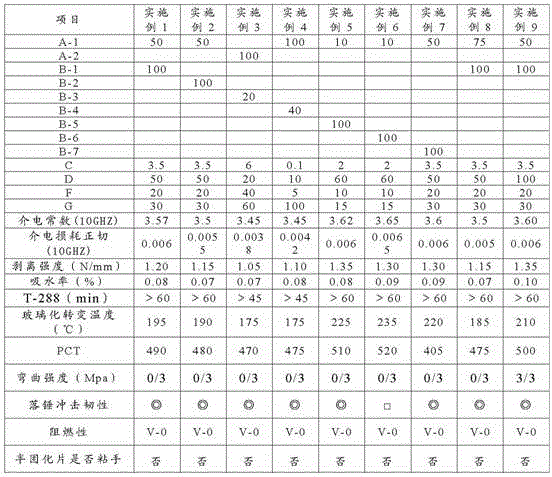

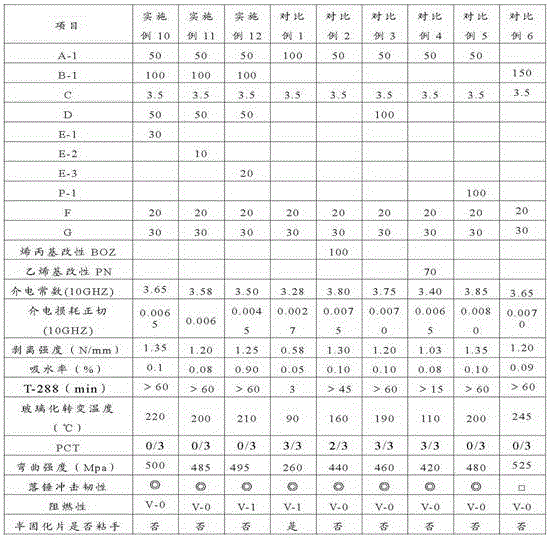

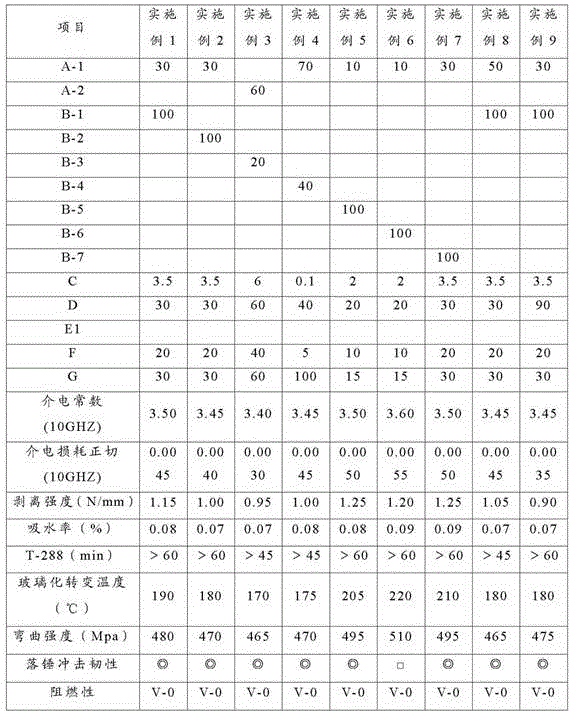

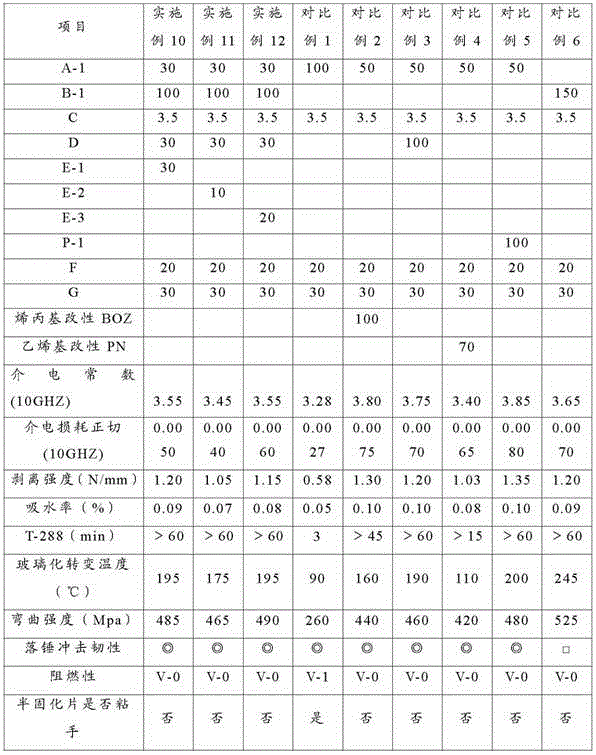

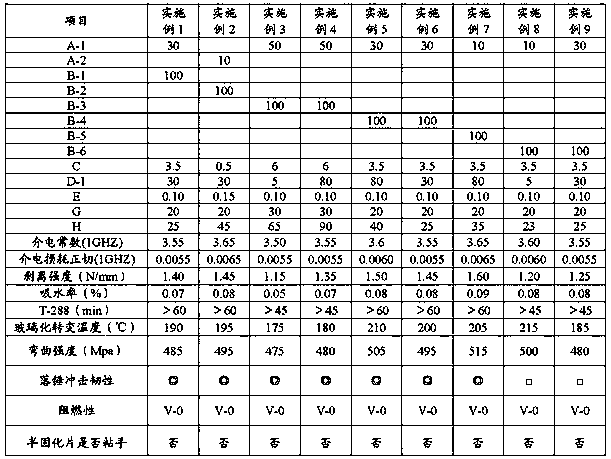

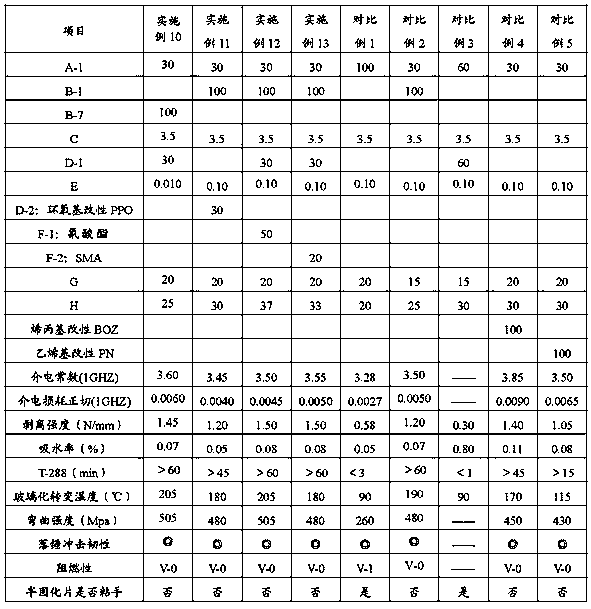

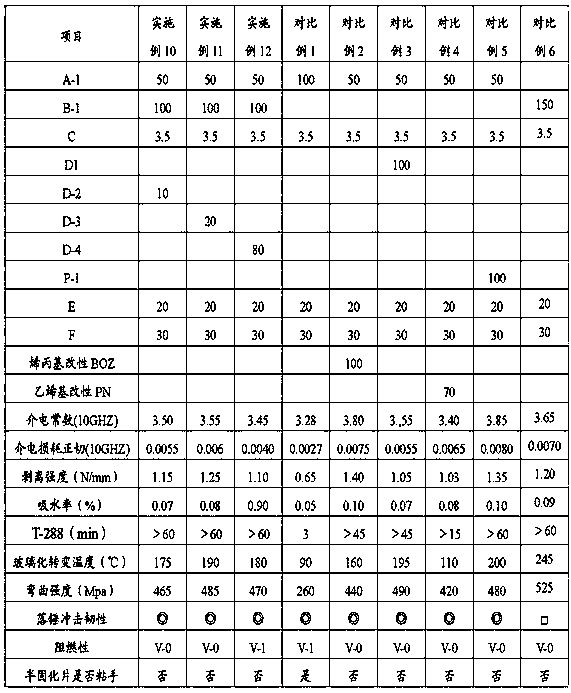

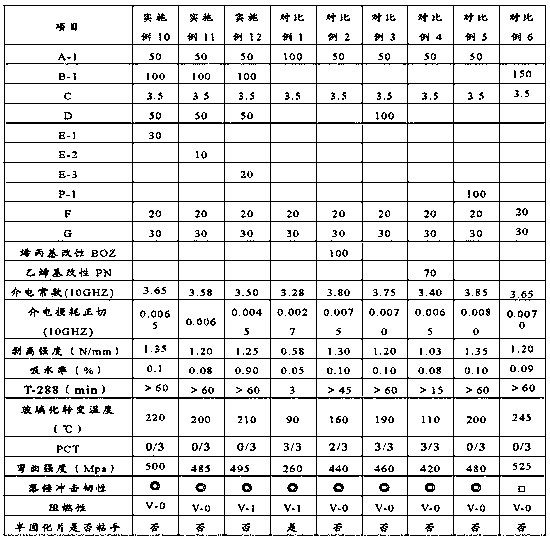

The present invention discloses a thermosetting resin composition, which comprises (calculated as the solid weight): (a) 10-80 parts of a hydrocarbon resin, (b) 20-100 parts of maleimide ester, (c) 0.1-8 parts of an initiator, and (d) 5-100 parts of an epoxy resin. According to the present invention, the maleimide ester having the polyfunctional long-chain structure and the rigid imide ring is used and is matched with the hydrocarbon resin having the flexibility to form the thermosetting composition, such that the thermosetting resin composition and the prepared printed circuit prepreg and laminated plate produced by using thermosetting resin composition have characteristics of excellent dielectric property, excellent heat resistance, excellent adhesion, excellent flame retardancy, excellent flexural strength, excellent toughness, high peel strength, low water absorption, excellent processability and the like through the interaction between the hydrocarbon resin and the maleimide ester.

Owner:SHENGYI TECH SUZHOU

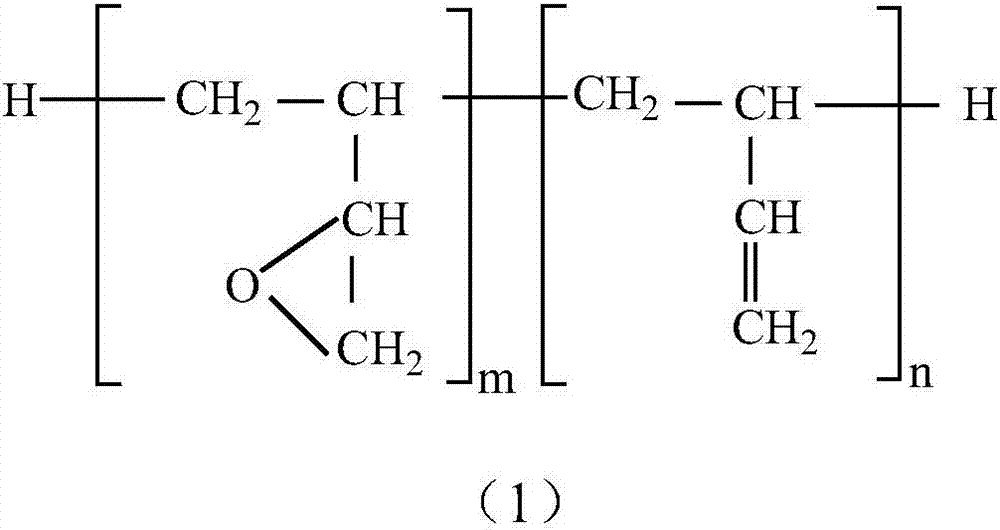

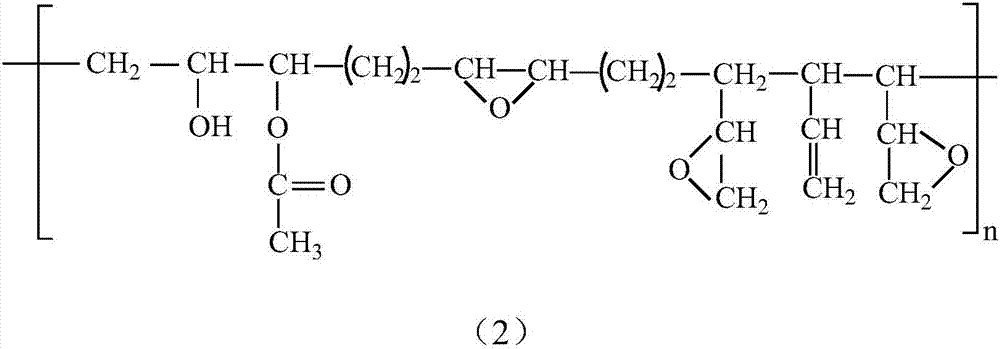

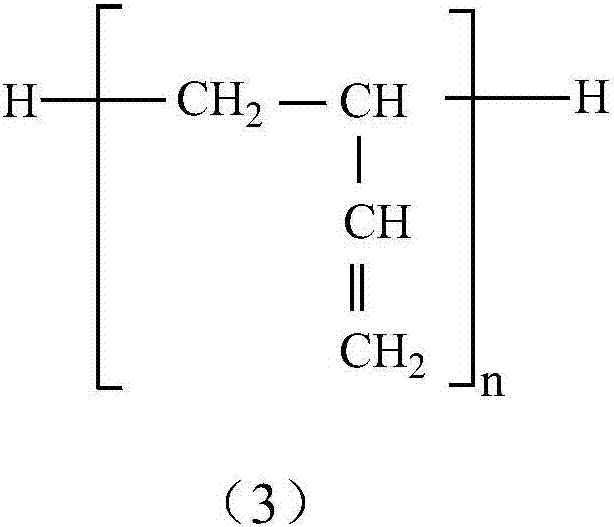

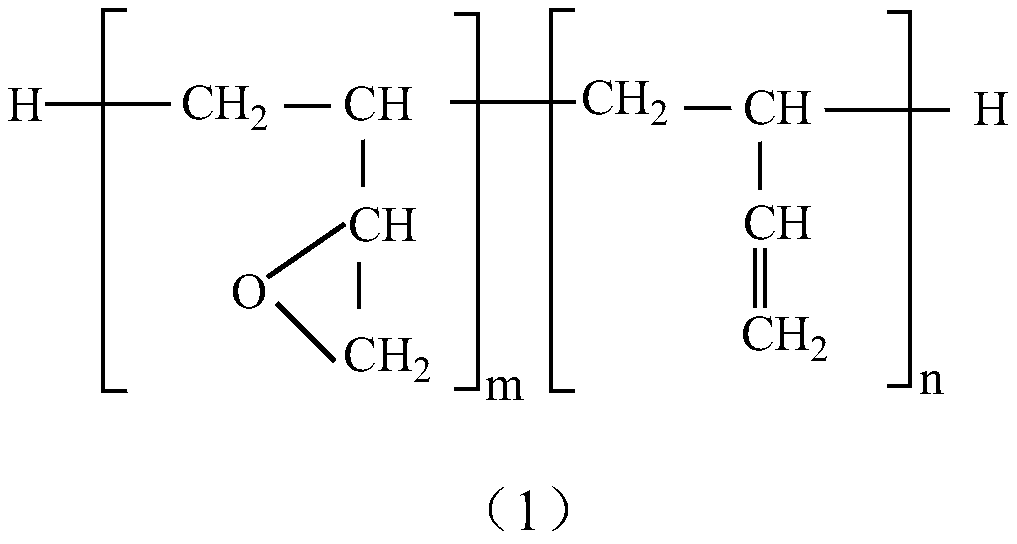

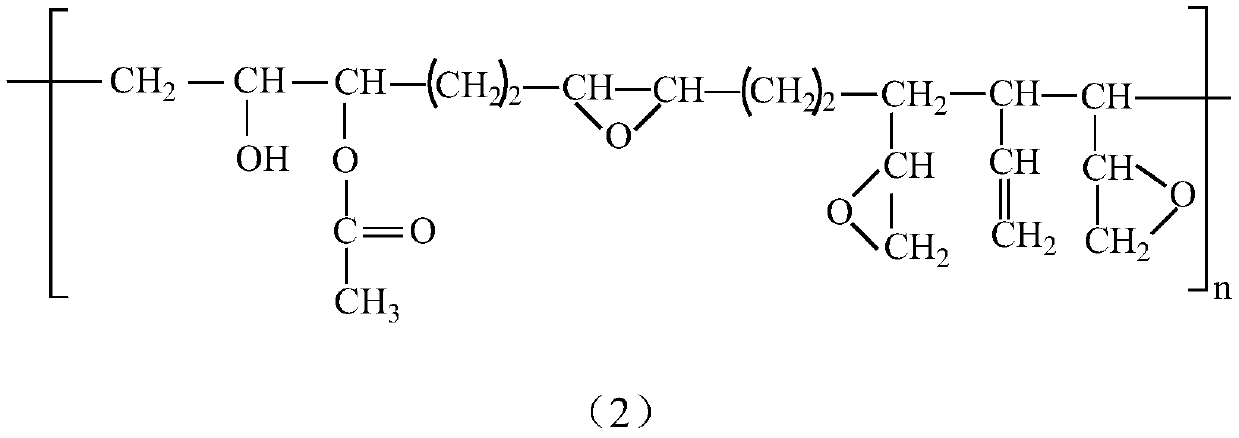

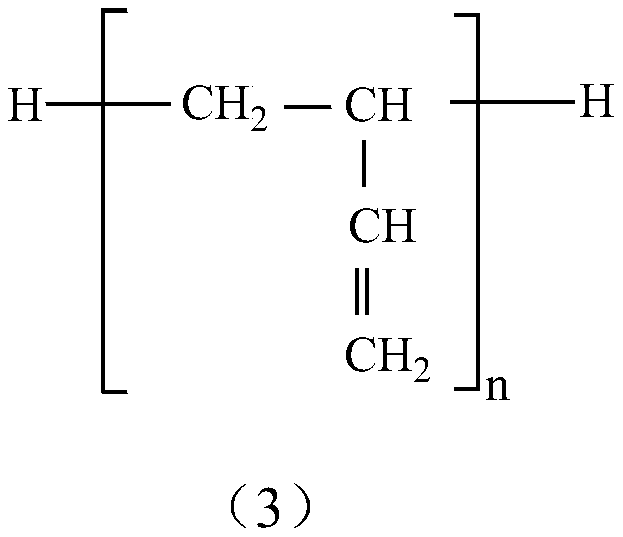

Modified polybutadiene prepolymer as well as preparation method and application thereof

ActiveCN107033517AImprove heat resistanceImprove toughnessSynthetic resin layered productsElectrical equipmentMetal foilCopper foil

The invention relates to a modified polybutadiene prepolymer as well as a preparation method and application thereof, resin composition prepared from the modified polybutadiene prepolymer, a prepreg prepared from the resin composition, a metal foil coated laminated board and a layer insulation film. The modified polybutadiene prepolymer is a prepolymer of an epoxy polybutadiene mixture, bismaleimide resin and cyanate ester in the weight ratio being 100: (10-60): (15-80). The problem that polybutadiene is incompatible with other resin is solved, the adhesion performance of a hydrocarbon resin system is improved, the peel strength between copper foil of the laminated board and the resin layer is improved, and the dielectric performance of the resin system is not affected. The brittleness of a maleimide cured product is improved by the aid of epoxy polybutadiene resin, polybutadiene and silica-containing butadiene.

Owner:SHENGYI TECH SUZHOU

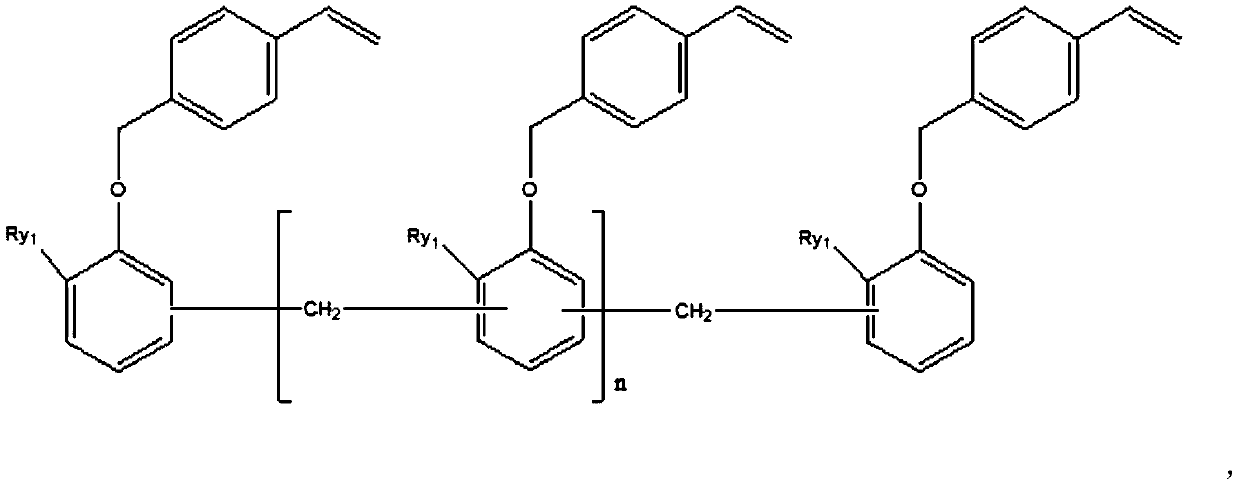

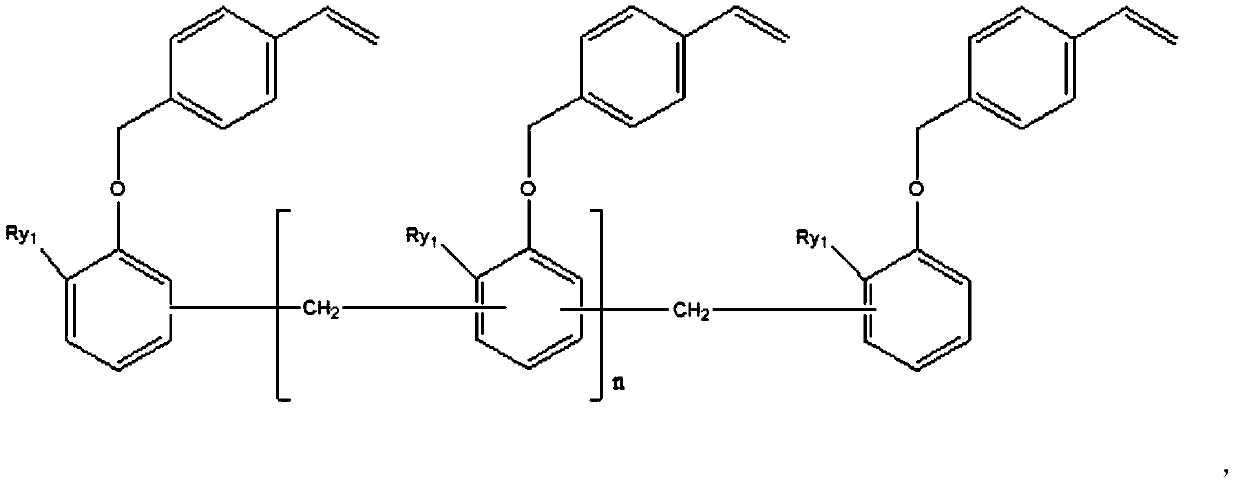

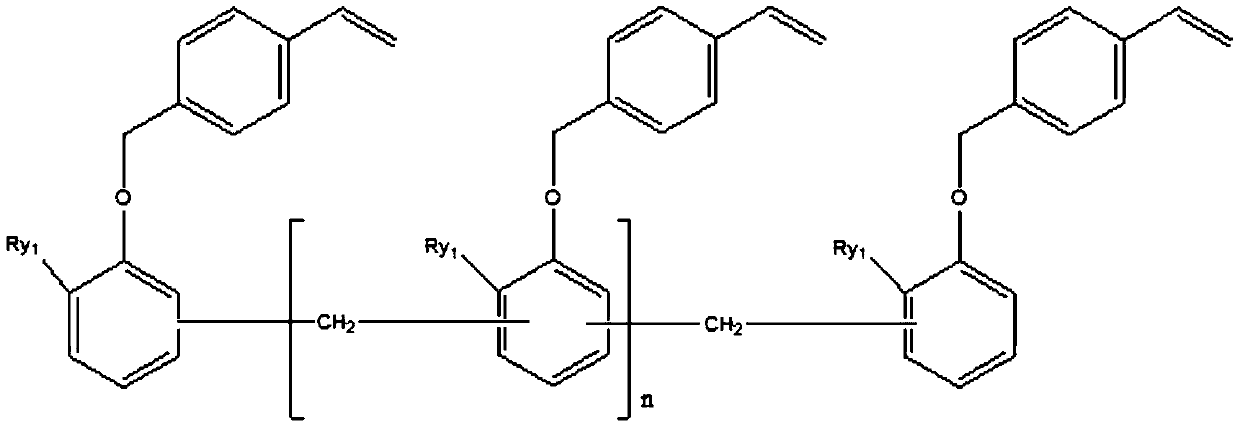

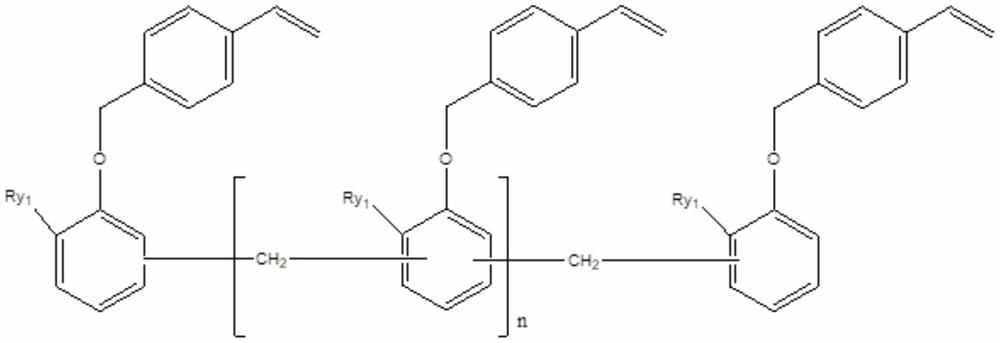

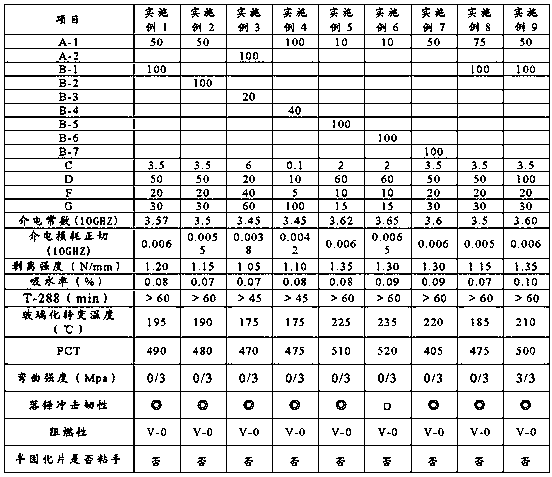

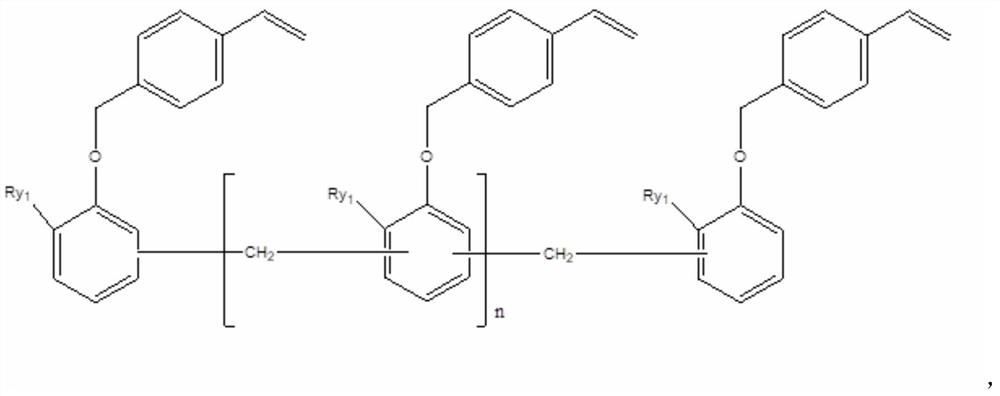

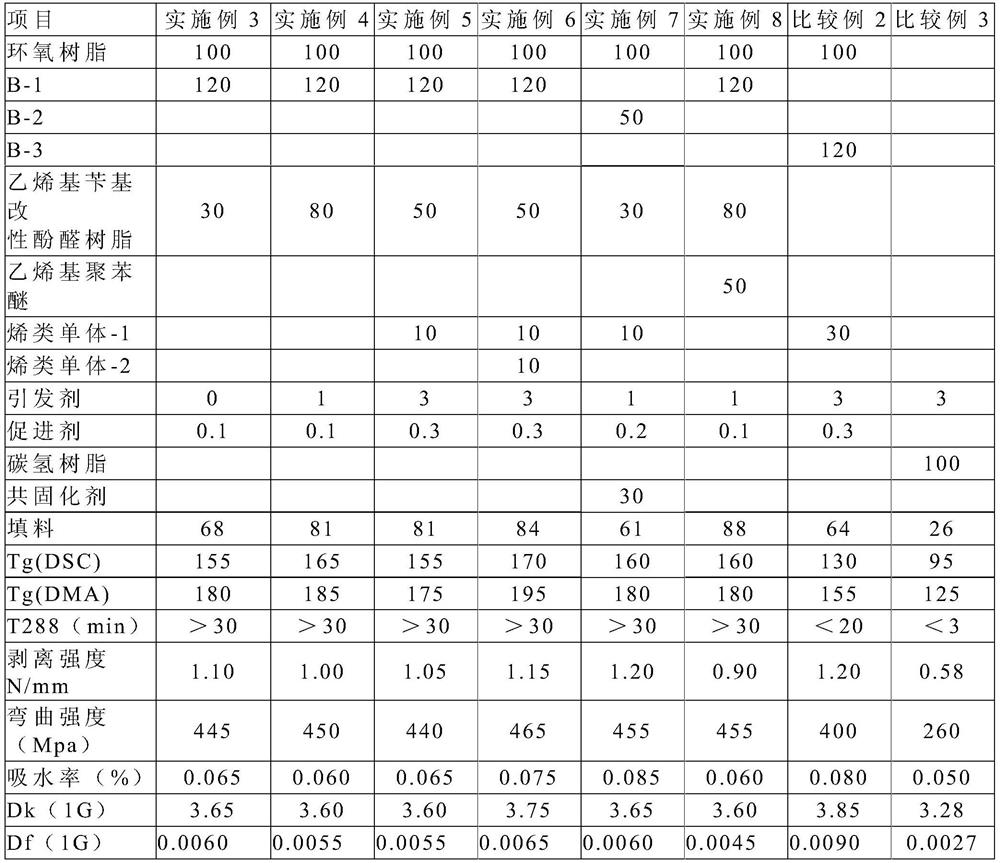

Thermosetting resin composition and prepreg and laminated board prepared by using composition

ActiveCN109867912AImprove heat resistanceHigh mechanical strengthMetal layered productsEpoxyAbsorption ratio

The present invention discloses a thermosetting resin composition. The composition comprises the following components, in parts by weight: (a) 100 parts of epoxy resin; (b) 50-200 parts of unsaturatedpolyester active ester resin; (c) 10-200 parts of vinyl benzyl modified phenolic resin; and (d) 0.05-4 parts of an accelerant. According to the composition provided by the invention, the unsaturatedpolyester active ester resin can effectively combine an active ester curing epoxy resin system, a hydrocarbon resin curing system and a vinyl benzyl modified phenolic resin system through chemical bonding, the excellent properties of the active ester curing epoxy system, the excellent properties of the hydrocarbon resin and the excellent properties of the vinyl benzyl modified phenolic resin system are combined effectively, so that the resin composition has excellent dielectric properties, heat resistance, strength, stiffness flexibility, high peeling strength, a low water absorption ratio anda low heat shrinkage ratio after being cured, and can be applied to high-speed high-frequency printed circuit boards.

Owner:SHENGYI TECH SUZHOU

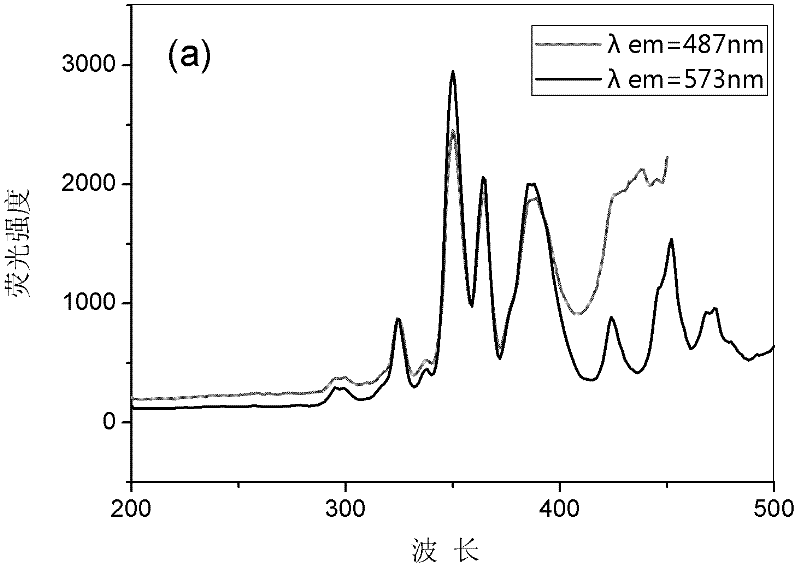

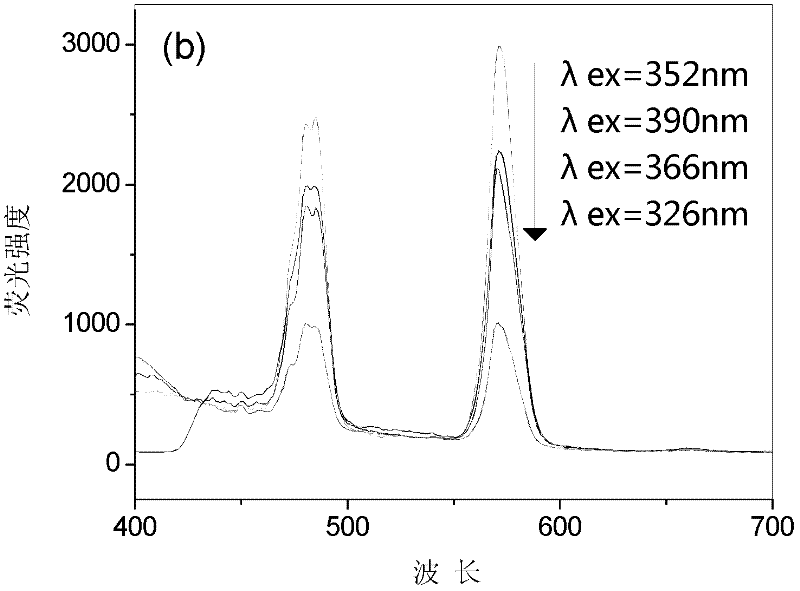

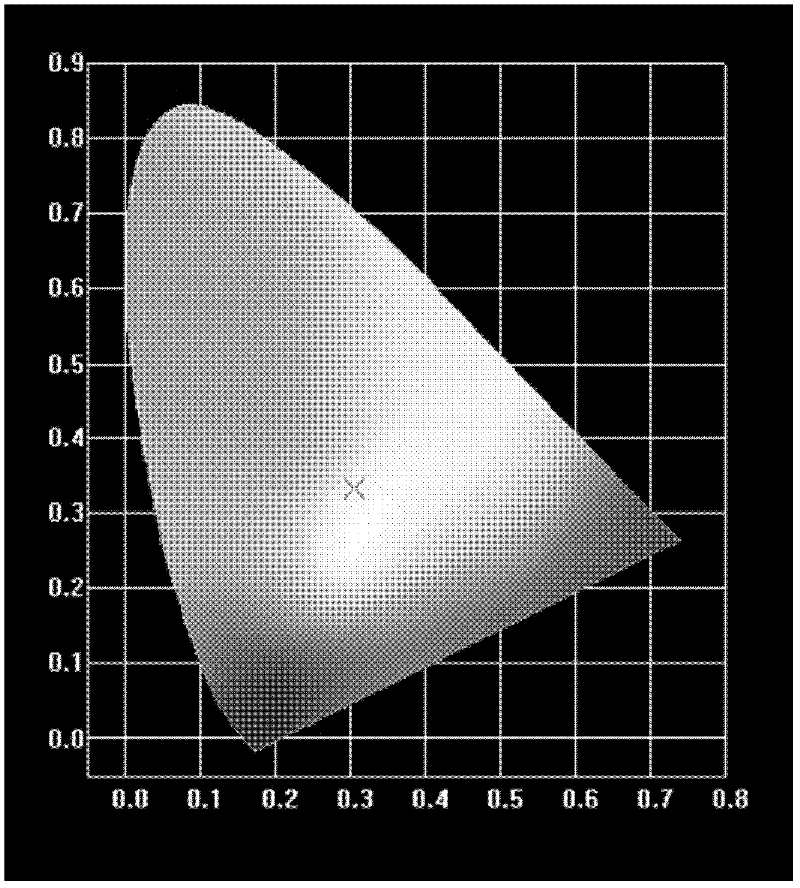

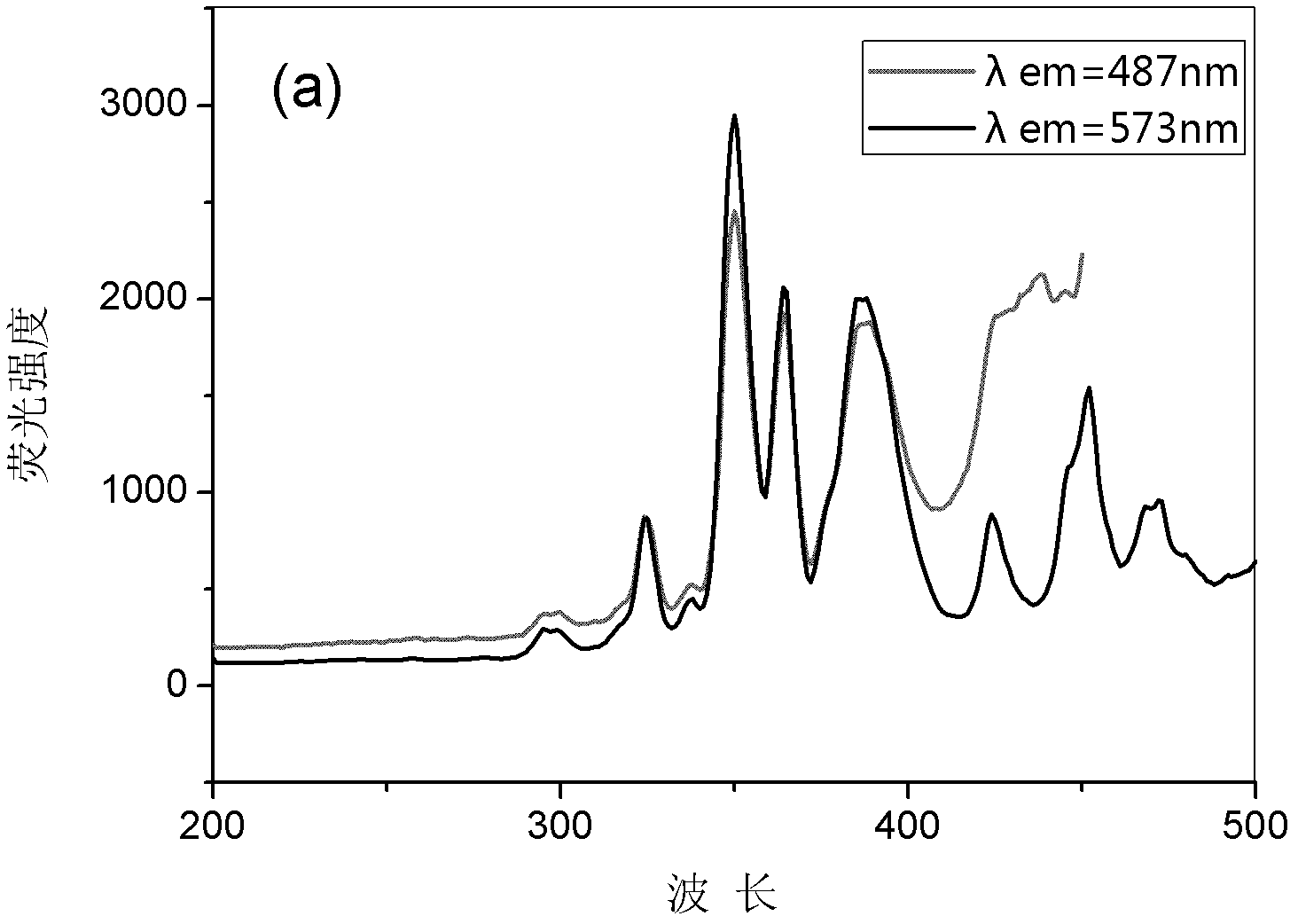

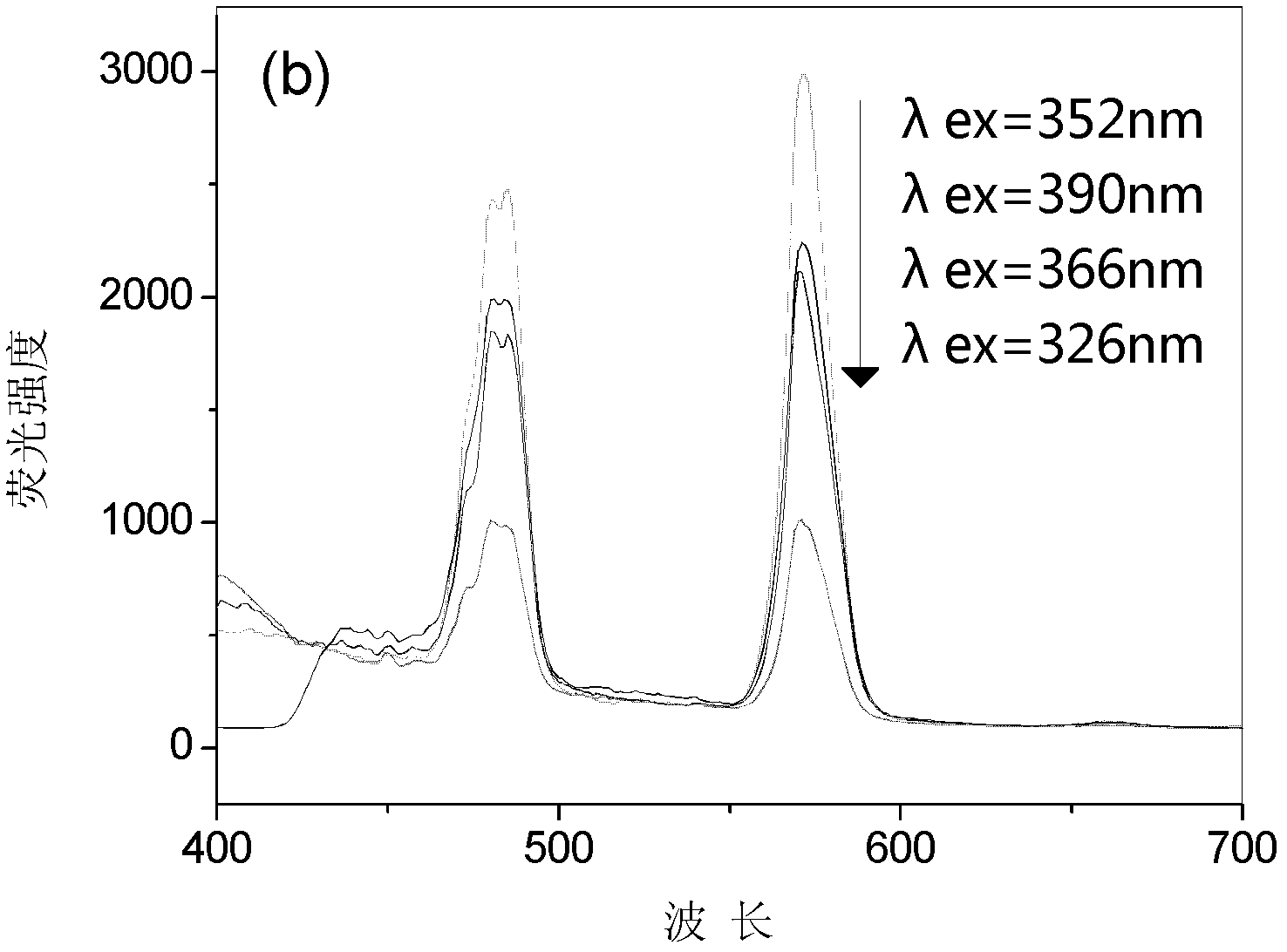

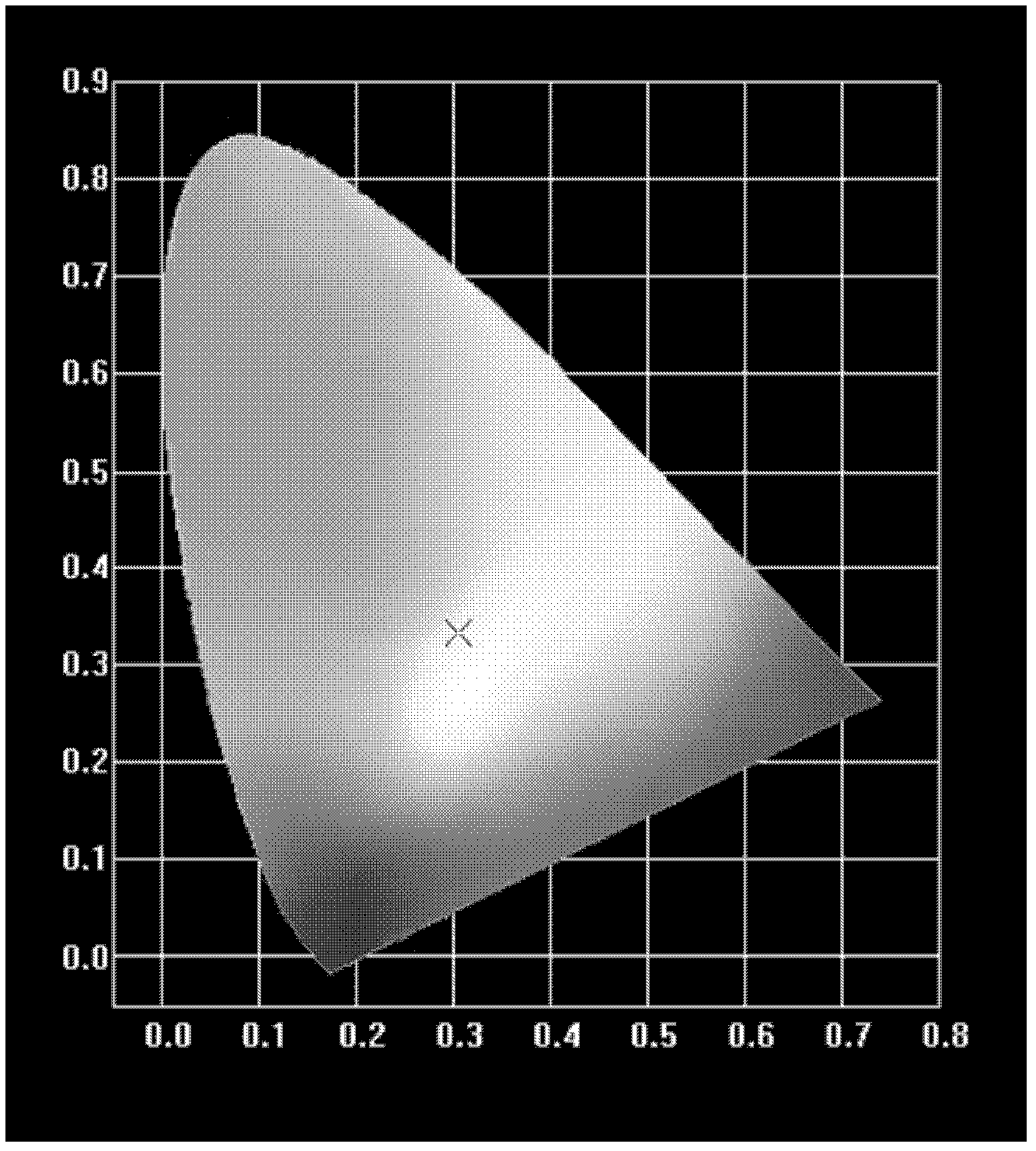

Low-temperature co-fired ceramic material emitting white light and preparation method thereof

The invention provides a low-temperature co-fired ceramic material emitting white light and a preparation method thereof. The ceramic material comprises the following components in percentage by mol: 10 to 20 percent of CaO, 20 to 30 percent of B2O3, 50 to 60 percent of SiO2, and 1 to 9 percent of optical activating agent ions. The invention also relates to the preparation method of the material, namely, a sol-gel method for preparing the low-temperature co-fired ceramic material emitting white light. The invention has the advantages that: 1, the preparation process is simple and advanced, the sintering temperature is low by adopting the Sol-gel method and is between 800 DEG C and 900 DEG C, the sintering shrink rate at the temperature is controllable between 13 percent and 17 percent, and a glass ceramic material has a flat and smooth surface, as well as higher strength; 2, the dielectric constant is adjustable between 4(1MHz) and 6 (1MHz), and the coefficient of dielectric loss is lower than 0.002; 3, the light emission intensity is high, the material can emit yellow and blue light under activation of ultraviolet light with the wavelength of between 320nm and 410nm, the white light obtained by mixing the blue light and the yellow light can be used for illuminating and displaying; and 4, based on the advantages, the low-temperature co-fired ceramic material can be applied to the fields of white light LED (Light Emitting Diode) lamps, integrated ceramic substrates and other electronic devices and semiconductors, as well as microelectronic packaging materials.

Owner:UNIV OF SCI & TECH BEIJING

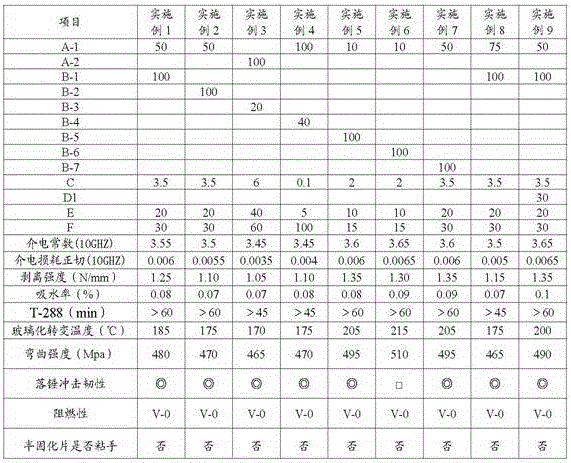

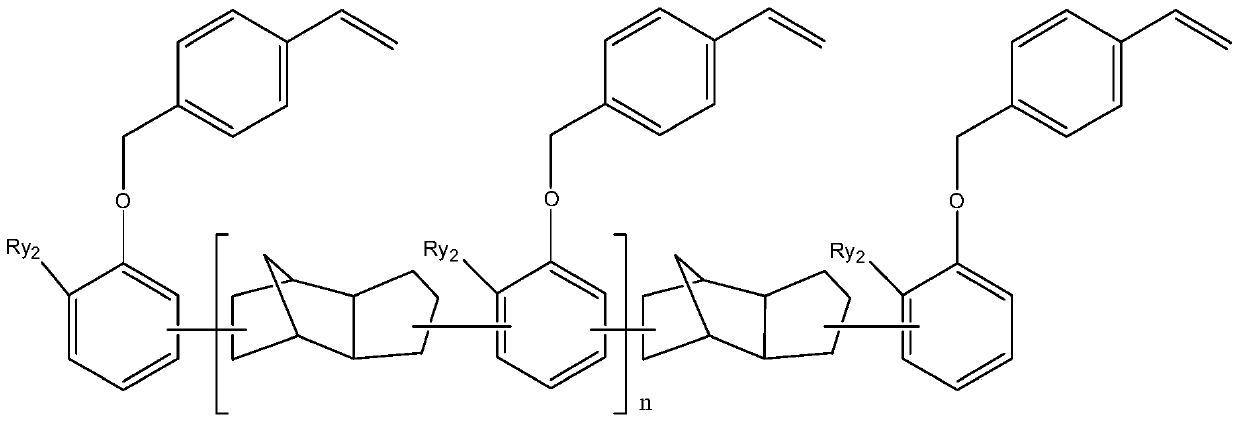

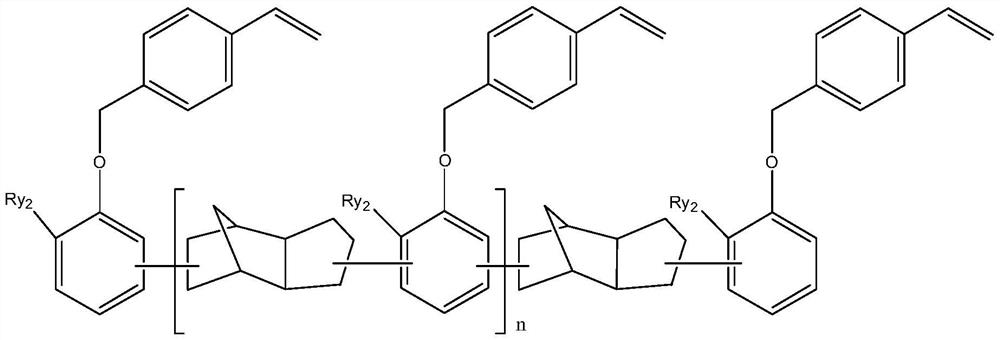

Thermosetting resin composition and prepreg made of thermosetting resin composition, as well as laminated board

ActiveCN106221126AImprove toughnessImprove heat resistanceSynthetic resin layered productsLaminationImideDielectric

The invention discloses a thermosetting resin composition which is prepared from the following components based on the weight of solids: (a) 10 to 100 parts of hydrcarbon resin, (b) 20 to 100 parts of maleimide ester, and (c) 0.1 to 8 parts of an initiator. According to the thermosetting resin composition, the maleimide ester with a polyfunctional long chain structure and a rigid imide ring works together with the flexible hydrcarbon resin to form a thermosetting composition, and the maleimide ester and the rigid imide ring react with each other, so that finally the thermosetting resin composition and a prepreg made of the thermosetting resin composition as well as a laminated board have the characteristics of excellent dielectric property, heat resistance, adhesion property, flame retardancy, bending strength and toughness, high peeling strength, low water absorption rate, excellent processing property and the like.

Owner:SHENGYI TECH SUZHOU

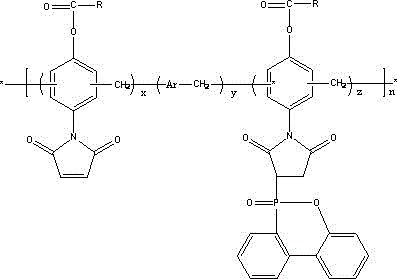

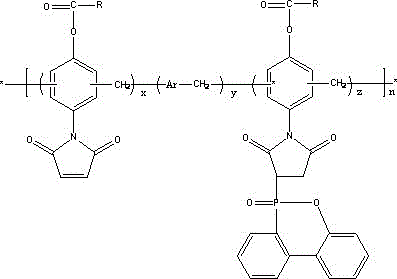

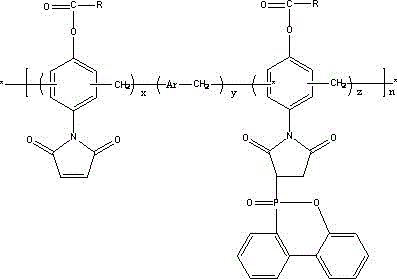

Thermosetting resin composition and prepregs and laminates produced by using the same

ActiveCN106349442AImprove toughnessImprove heat resistanceSynthetic resin layered productsElectrical equipmentImideEpoxy

The invention discloses a thermosetting resin composition. The thermosetting resin composition is prepared from, by solid weight: (a) 10-80 parts of hydrocarbon resin; (b) 100 parts of phosphoric maleimide; (c) 0.1-8 parts of initiator; (d) 5-100 parts of epoxy resin. he thermosetting resin composition applies the maleimide with multi-functional long-chain structure and rigid imide ring and combines with a flexible hydrocarbon resin to form a thermosetting composition through the interaction, and finally makes the thermosetting resin composition and prepregs and laminates produced by using the same for the printed circuit have the characteristics of excellent dielectrical property, heat resistance, adhesion, flame resistance, bending strength, toughness, high peel strength, low water absorption, excellent processing performance and others.

Owner:SHENGYI TECH SUZHOU

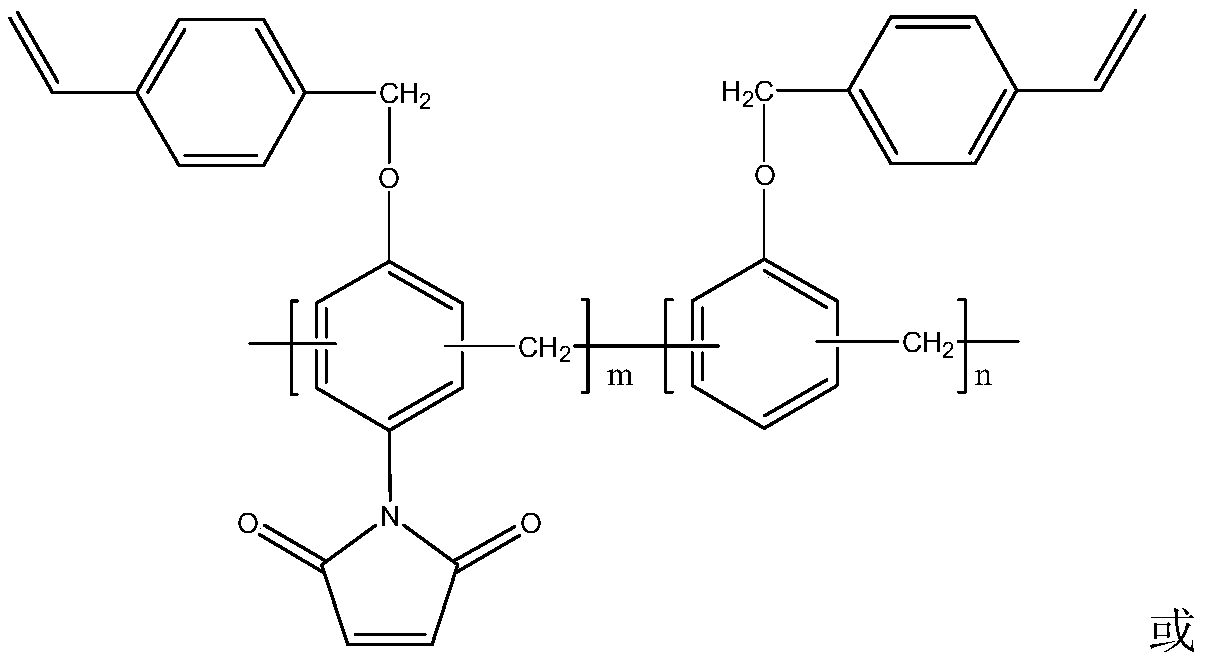

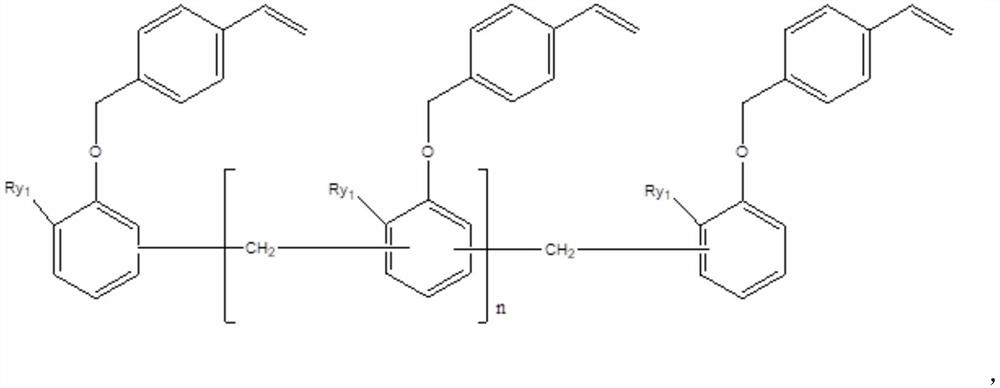

Thermosetting resin composition and prepreg and laminated board prepared by applying same

ActiveCN109943047AImprove heat resistanceHigh mechanical strengthSynthetic resin layered productsMetal layered productsEpoxyHeat resistance

The invention discloses a thermosetting resin composition which is prepared from the following components in parts by weight: (a) 100 parts of epoxy resin, (b) 50-200 parts of unsaturated polyester active ester resin, (c) 10-200 parts of vinyl modified polyphenyl ether ester, and (d) 0.05-4 parts of an accelerant. The unsaturated polyester active ester resin can combine an active ester cured epoxyresin system, a hydrocarbon resin curing system and a polyphenyl ether system effectively by means of chemical bonds and combine excellent performance of the active ester cured epoxy resin system, the hydrocarbon resin curing system and the polyphenyl ether system effectively, so that the resin composition which is cured has excellent dielectric property, heat resistance, strength, stiffness andflexibility, high peel strength, low water absorption and small heat shrinkage, and can be applied to high speed and high frequency printed circuit boards.

Owner:SHENGYI TECH SUZHOU

Thermosetting resin composition and prepreg and laminated board prepared from same

ActiveCN106243430AImprove toughnessImprove heat resistanceSynthetic resin layered productsElectrical equipmentImideHeat resistance

The invention discloses a thermosetting resin composition. The thermosetting resin composition is prepared from, by solid weight, 10-100 parts of hydrocarbon resin, 20-100 parts of phosphorus-containing maleimide ester and 0.1-8 parts of an initiating agent. According to the thermosetting resin composition, the maleimide ester with multifunctional long-strain structures and rigid imide rings is adopted to cooperate with the flexible hydrocarbon resin to form the thermosetting resin composition, the maleimide ester and the hydrocarbon resin achieve interaction, and finally the thermosetting resin composition and prepreg and a laminated board which are used for a printed circuit and prepared from the thermosetting resin composition have the advantages of being excellent in dielectric property, heat resistance, adhesive property, flame resistance, bending strength and toughness, high in peel strength, low in water absorption, excellent in processing technology property and the like.

Owner:SHENGYI TECH SUZHOU

Thermosetting resin composition and prepregs and laminates produced by using the same

ActiveCN106349643AImprove toughnessImprove rigiditySynthetic resin layered productsLaminationImideHeat resistance

The invention discloses a thermosetting resin composition. The thermosetting resin composition is prepared from, by solid weight: (a) 10-100 parts of hydrocarbon resin; (b) 20-100 parts of maleimide; (c) 0.1-8 parts of initiator; (d) 10-100 parts of cyanate ester resin. The thermosetting resin composition applies the maleimide with multi-functional long-chain structure and rigid imide ring and combines with a flexible hydrocarbon resin to form a thermosetting composition through the interaction, and finally makes the thermosetting resin composition and prepregs and laminates produced by using the same for the printed circuit have the characteristics of excellent dielectrical property, heat resistance, adhesion, flame resistance, bending strength, toughness, high peel strength, low water absorption, excellent processing performance and others.

Owner:SHENGYI TECH SUZHOU

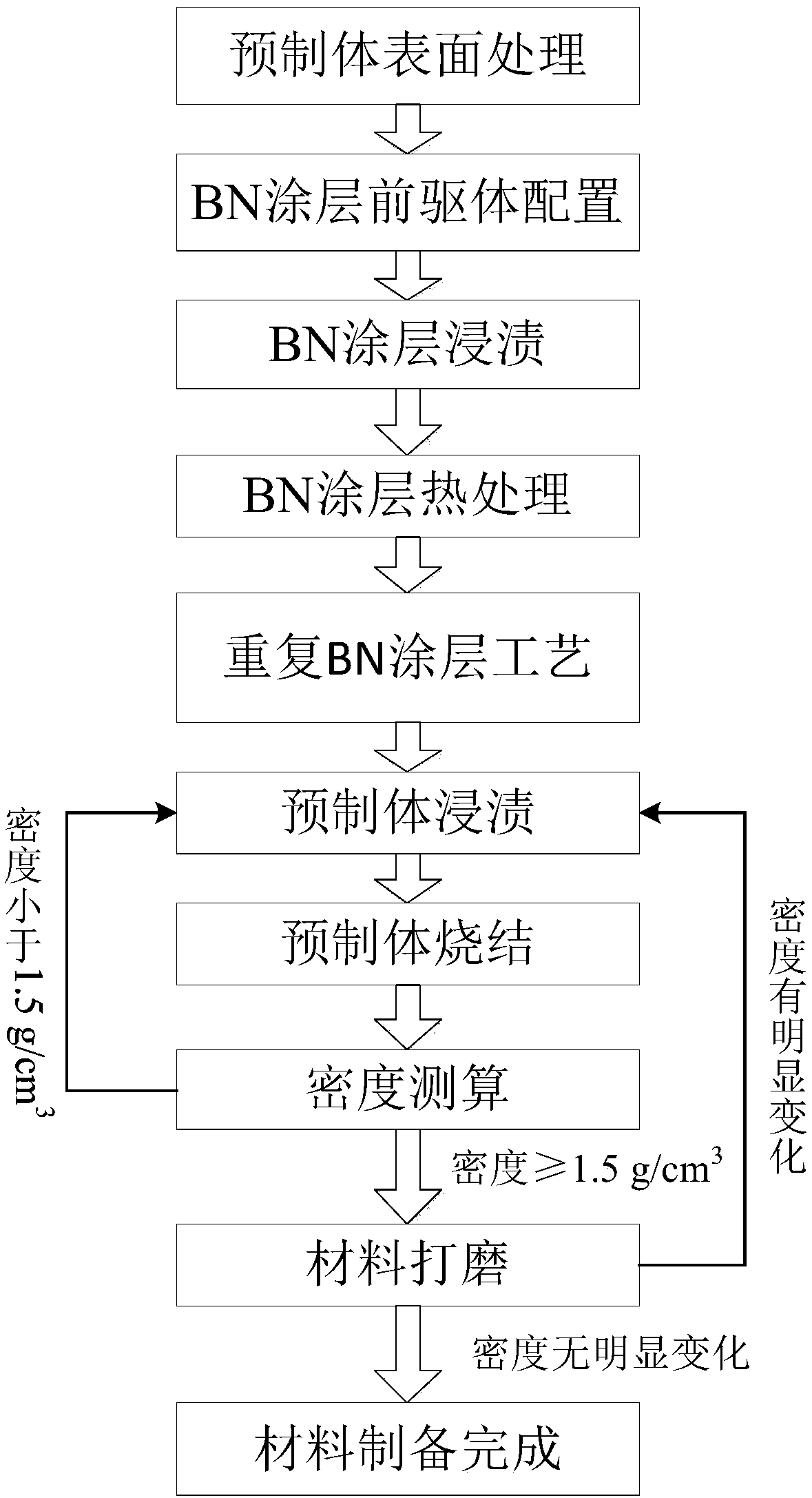

BN (Boron nitride)-modified SiO2 composite material and preparation method thereof

The invention relates to a BN (Boron nitride) coating modified SiO2f / SiO2 composite material for a radar dome and an antenna window and a preparation method thereof. The method comprises the followingsteps: surface pre-treatment, preparation of a BN coating precursor, dipping of a BN coating, thermal treatment of the BN coating, dipping of preforms, sintering of preforms, density measurement andmaterial grinding. The preparation process disclosed by the invention is simple, a period is short, the density of a material can reach 1.8g / cm<3>, the bending strength can reach 120MPa, a dielectricconstant is less than or equal to 3, dielectric loss under frequency of 2GPa to 18GPa is not more than 0.02, the working can be continuously carried out for 10 minutes at a high temperature of 800 DEGC, and an instantaneous working temperature can reach 1200 DEG C. The BN-modified SiO2f / SiO2 composite material and the preparation method disclosed by the invention have the advantages that the moisture absorption prevention ability is good, the problem that the characteristics including easiness for crystallization, low densification degree and mechanical strength of an existing SiO2f / SiO2 composite material cannot meet a use requirement is solved, and the density and mechanical performance of the material are improved.

Owner:JIANGXI JIAJIEXINDA NEW MATERIAL TECH CO LTD

Thermosetting resin composition and prepreg and laminated board manufactured from same

ActiveCN106336662AImprove toughnessImprove heat resistanceSynthetic resin layered productsElectrical equipmentImideHeat resistance

The invention discloses a thermosetting resin composition. The thermosetting resin composition is prepared from a, 10-100 parts of hydrocarbon resin, b, 20-100 parts of maleimide ester, c, 0.1-8 parts of initiator, and d, 10-100 parts of allyl modified polyphenyl ether resin according to the solid weight. Maleimide ester with a multifunctional long chain structure and rigid imide rings is adopted and matched with the flexible hydrocarbon resin to form the thermosetting resin composition, maleimide ester and the hydrocarbon resin mutually act, and finally the thermosetting resin composition and a prepreg and laminated board manufactured from the same and used for a printed circuit have the advantages of excellent dielectric performance, heat resistance, adhesion, flame retardance, bending strength and toughness, high peel strength, low water absorption rate, excellent processing process performance and the like.

Owner:SHENGYI TECH SUZHOU

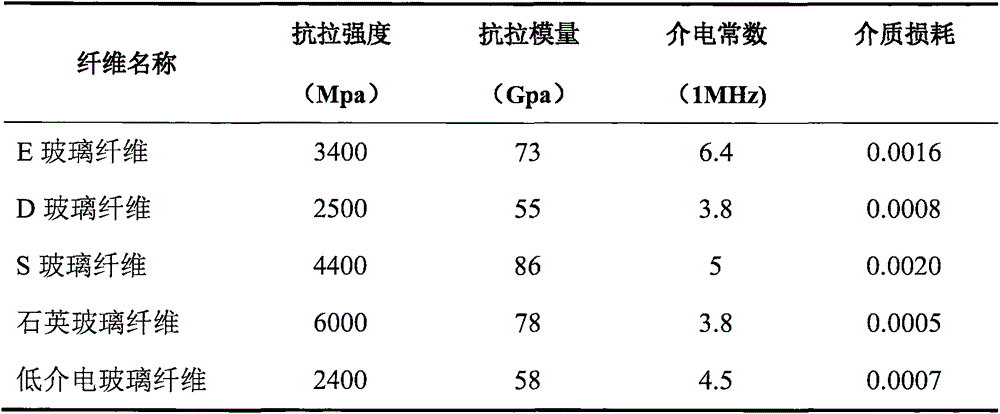

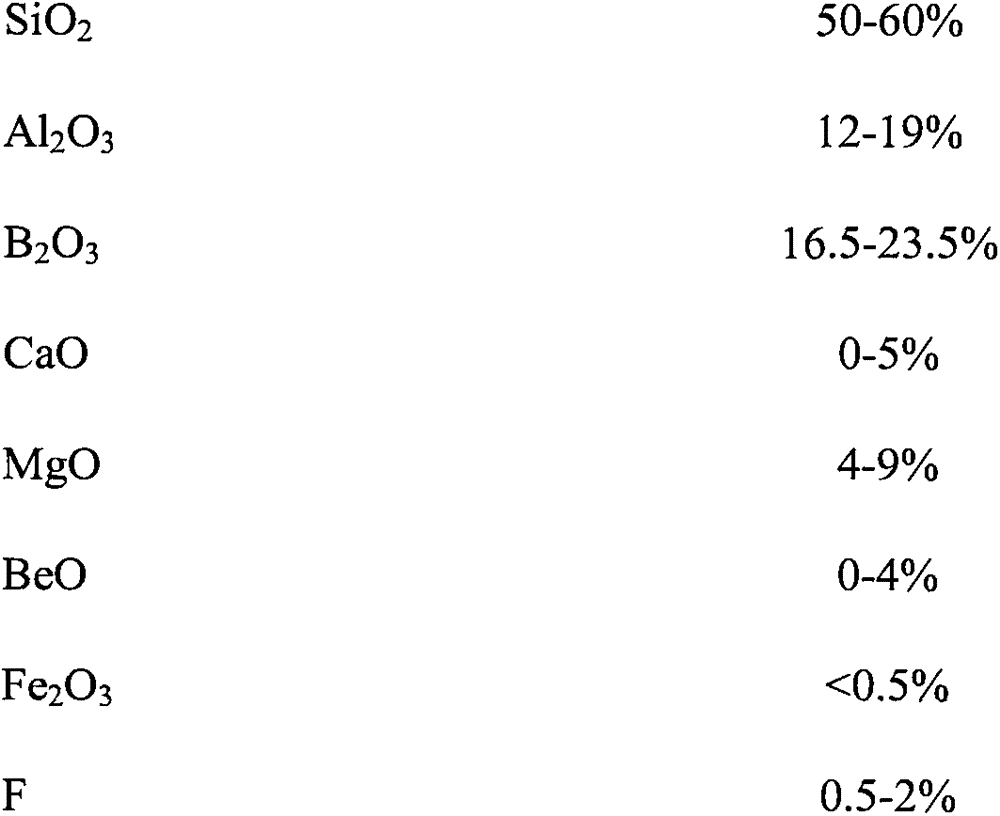

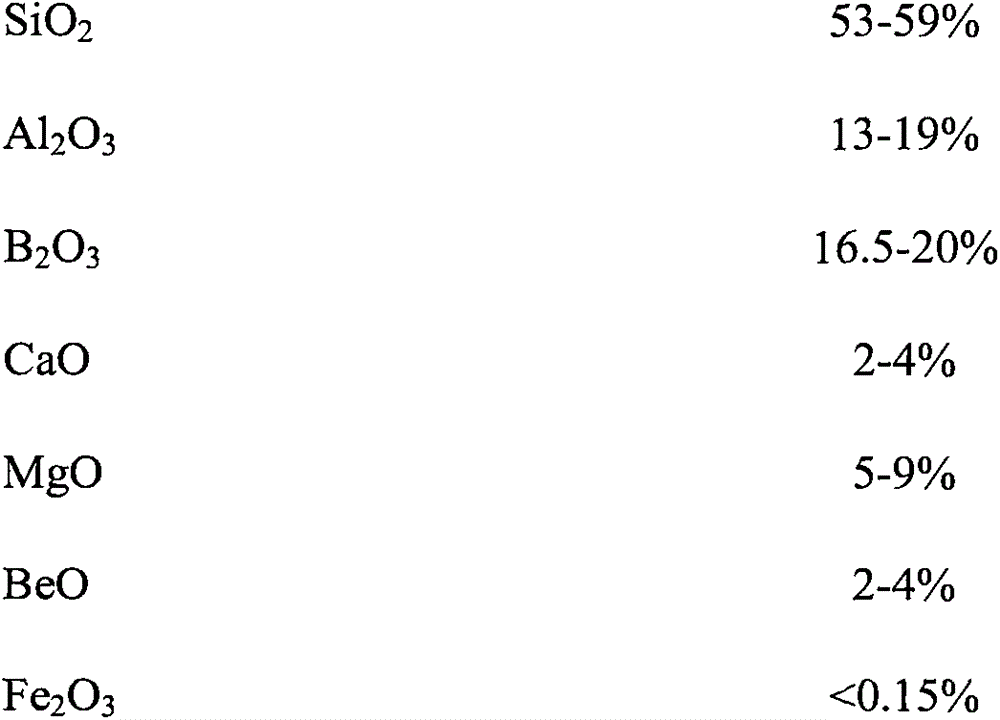

High-strength high-modulus low-dielectric constant fiberglass

InactiveCN106830692AReduce the difficulty of meltingDoes not affect dielectric propertiesGlass making apparatusSemiconductor/solid-state device detailsGlass fiberHigh intensity

The invention belongs to the technical field of glass fibers, in particular to a glass fiber with high strength, high modulus and low dielectric constant. The glass fibers are characterized as comprising BeO.

Owner:王飞

Silicon dioxide aerogel based composite shielding layer and preparation method thereof

The invention discloses a silicon dioxide aerogel based composite shielding layer material and a preparation method thereof. The preparation method comprises the following steps: soaking organic polyurethane foams into silicon dioxide ceramic slurry, performing vacuum soaking, taking out foams with the silicon dioxide ceramic slurry, uniformly extruding, drying, sintering, soaking into sol, adjusting the pH value, performing gelatination on the sol inside silicon dioxide foamed ceramic for 10 minutes to 3 hours, performing solvent exchange in absolute ethyl alcohol, and performing supercritical drying, thereby obtaining the silicon dioxide aerogel based composite shielding layer material. The composite shielding layer material is a high-strength light electromagnetic shielding material ofa micro-nano composite porous structure. Due to strong dense pore ribs in the silicon dioxide foamed ceramic, a good support property is achieved, the nano pore silicon dioxide aerogel among pore ribsis excellent in dielectric property of electromagnetic shielding, and the material has relatively good support strength for cores, is small in brittleness, is not liable to crack in the preparation process and is relatively good in dielectric property.

Owner:CHANGAN UNIV

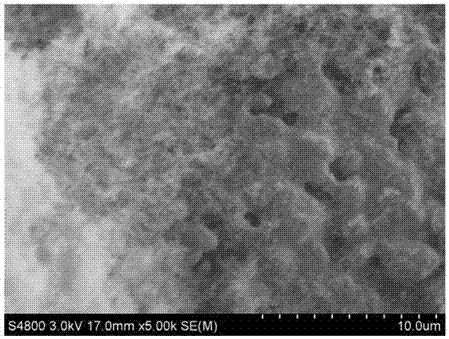

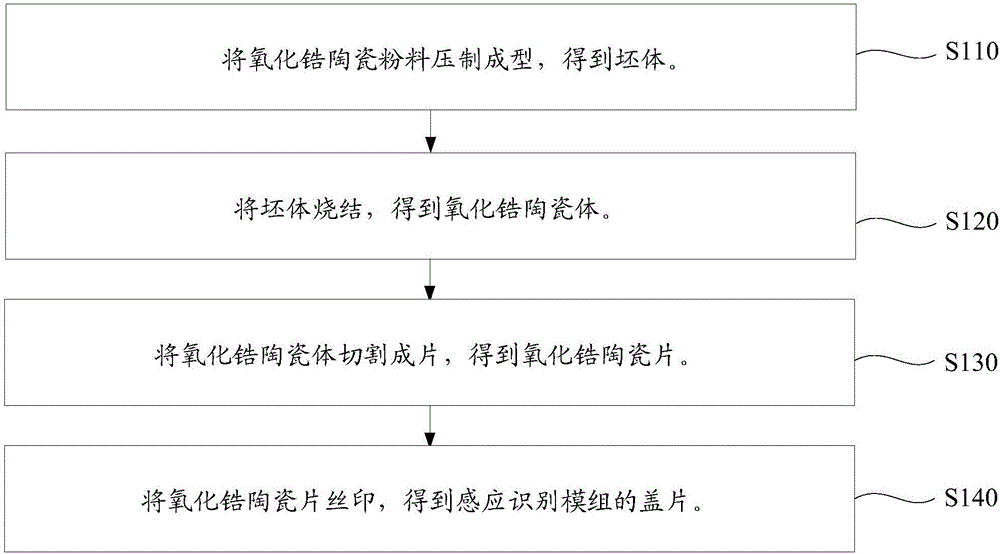

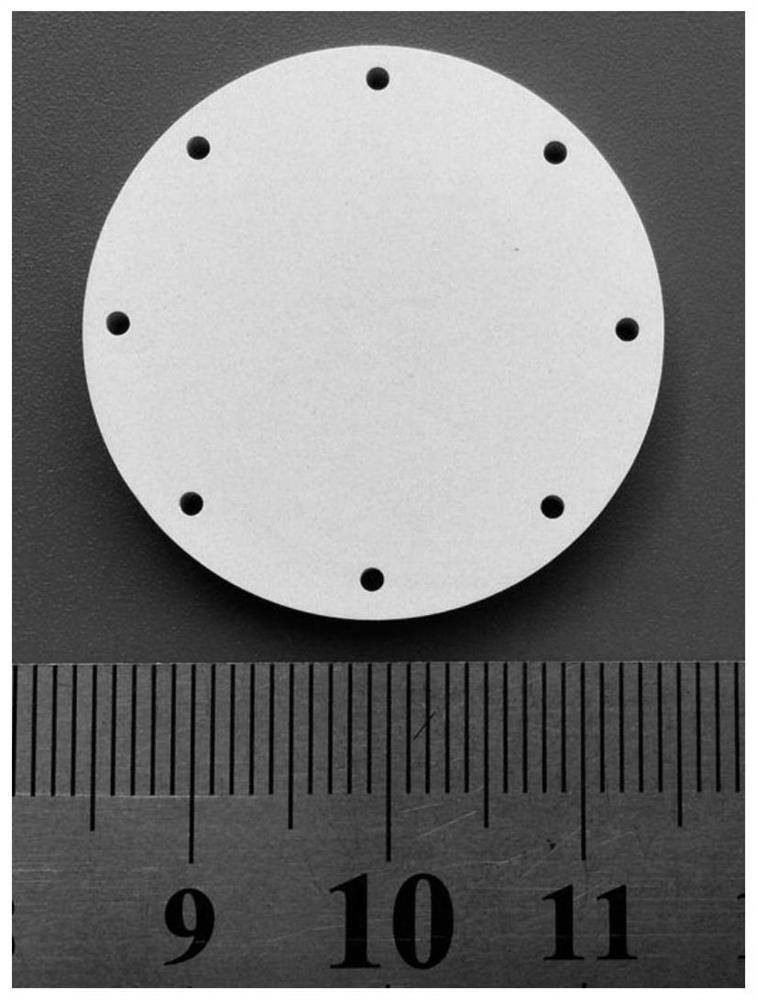

Cover plate of induction identification module, and preparation method and application thereof

ActiveCN106778553AHigh densityHigh strengthPrint image acquisitionScreen printingUltimate tensile strength

The invention relates to a cover plate of an induction identification module, and a preparation method and an application thereof. The preparation method of the cover plate of the induction identification module comprises the following steps: press forming zirconia ceramic powder to obtain a blank; sintering the blank to obtain a zirconia ceramic body; cutting the zirconia ceramic body into pieces to obtain zirconia ceramic pieces, wherein the cutting process parameters are as follows: the line diameter of a cutting line is 0.14-0.30mm, the line feeding speed is 0.1-5mm / min, the line speed is 1000-1500m / min, the line tension is 10-50N, and the tilt angle is -7 degrees to 7 degrees; and perform silk screen printing on the zirconia ceramic pieces to obtain the cover plate of the induction identification module. The cover plate of the induction identification module prepared by the preparation method of the cover plate of the induction identification module has relatively high strength, better density and higher dielectric property.

Owner:SHENZHEN SUNTECH ADVANCED CERAMICS

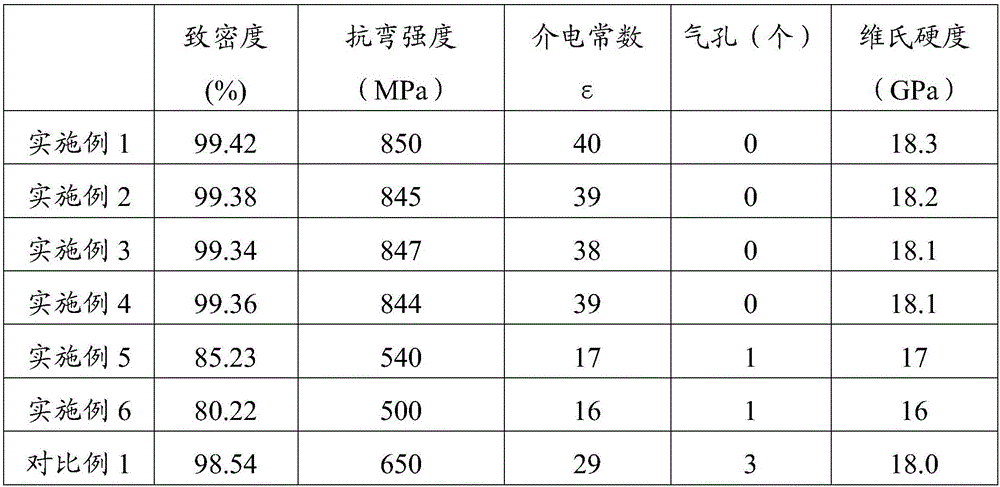

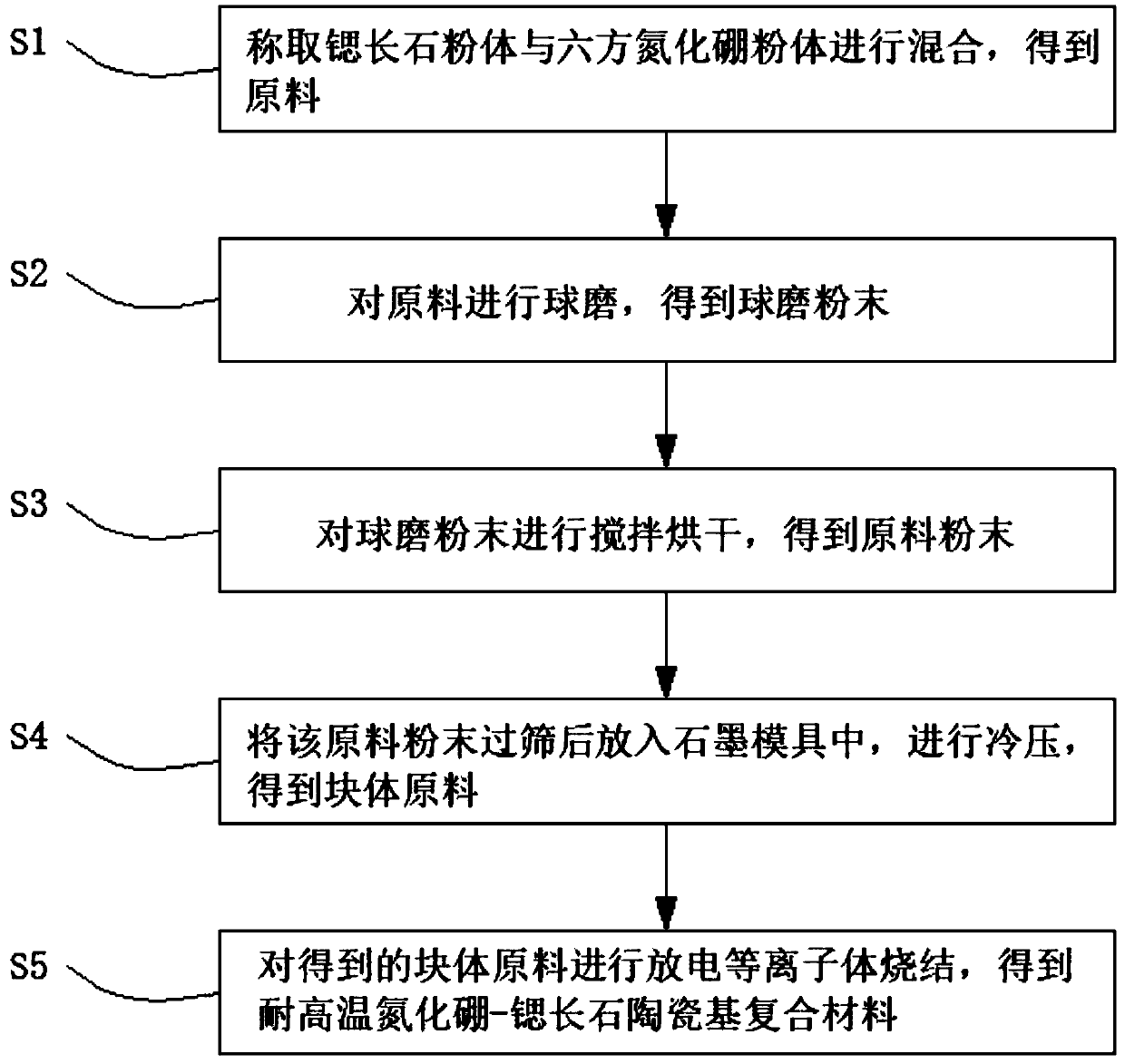

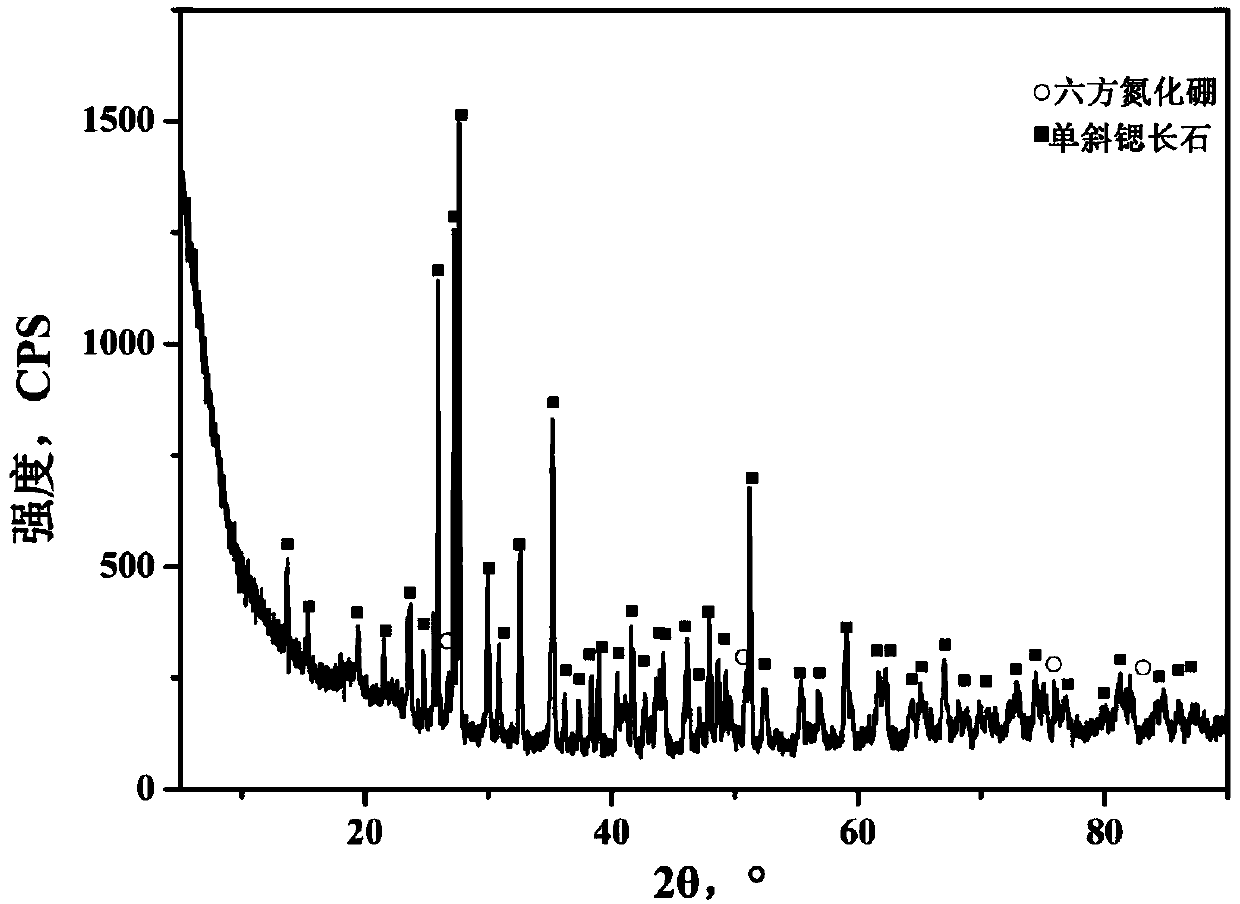

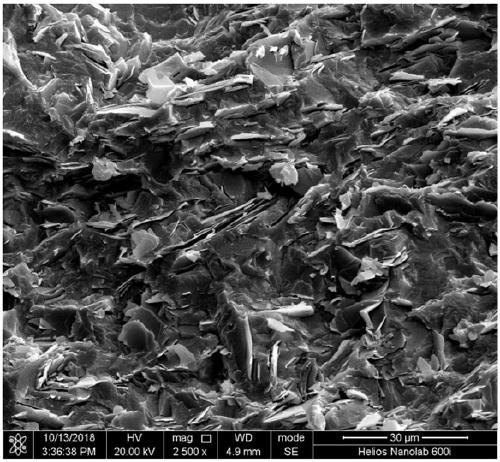

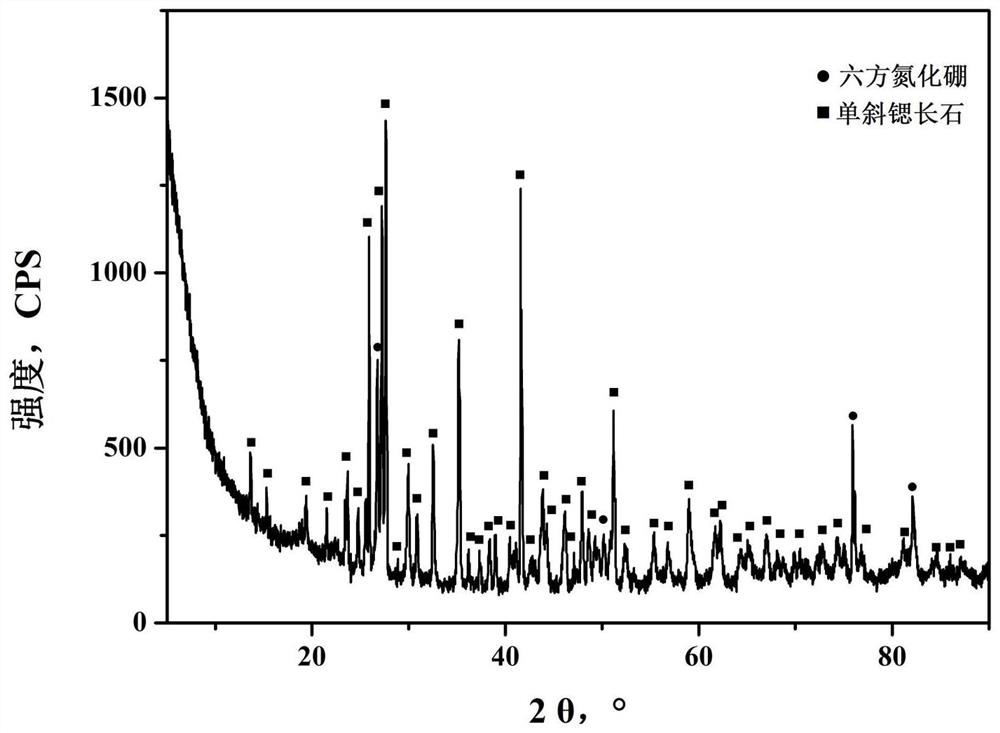

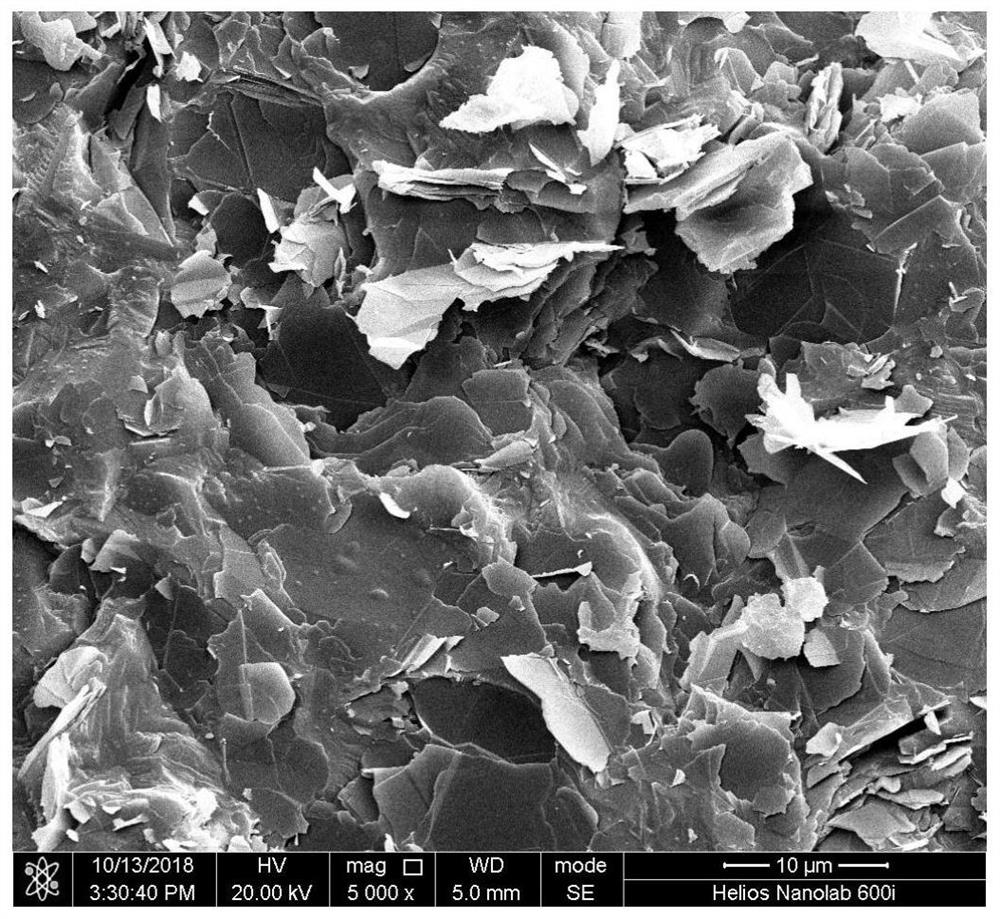

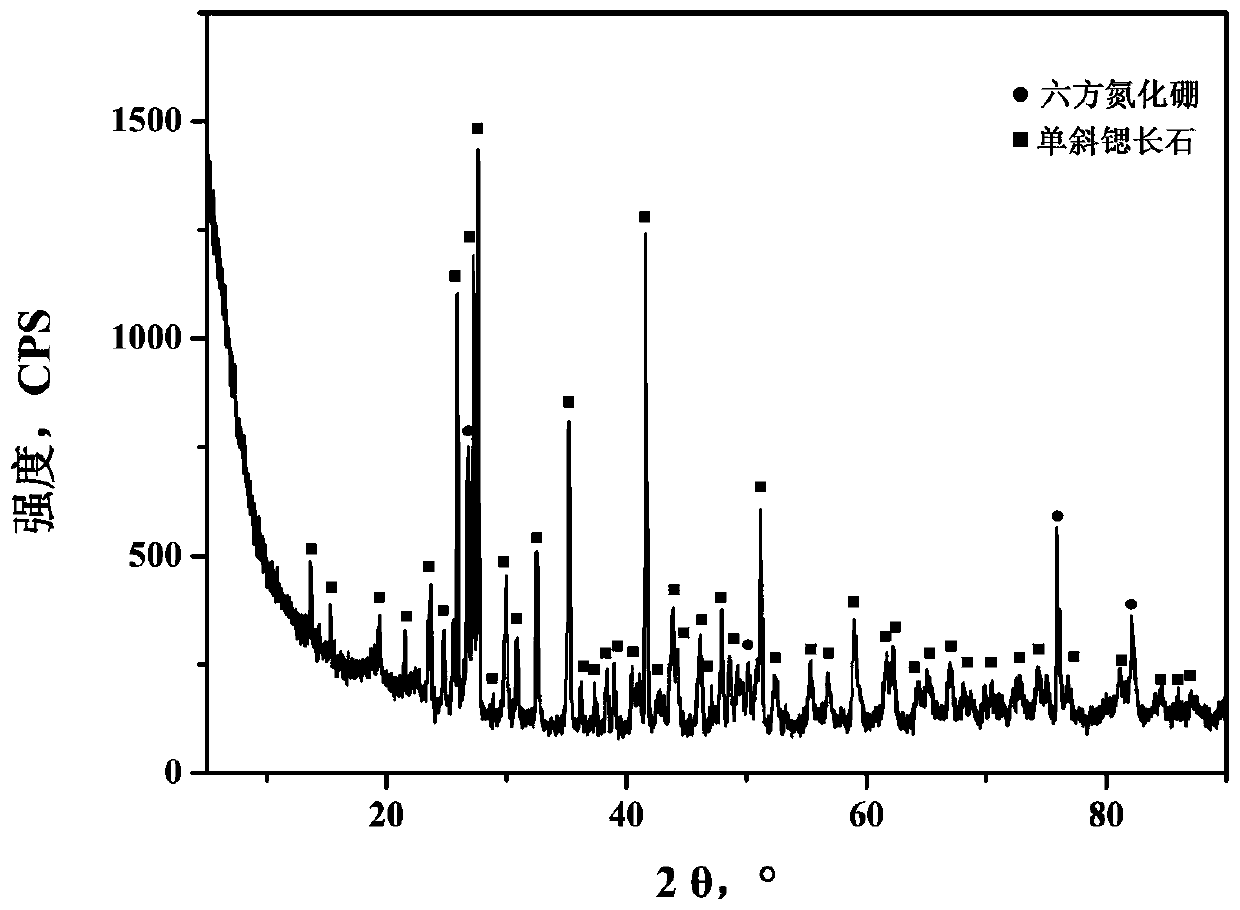

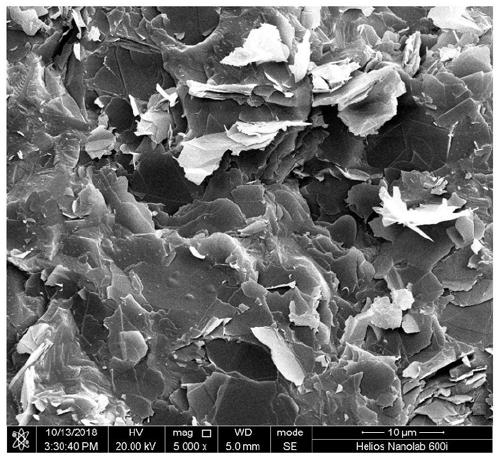

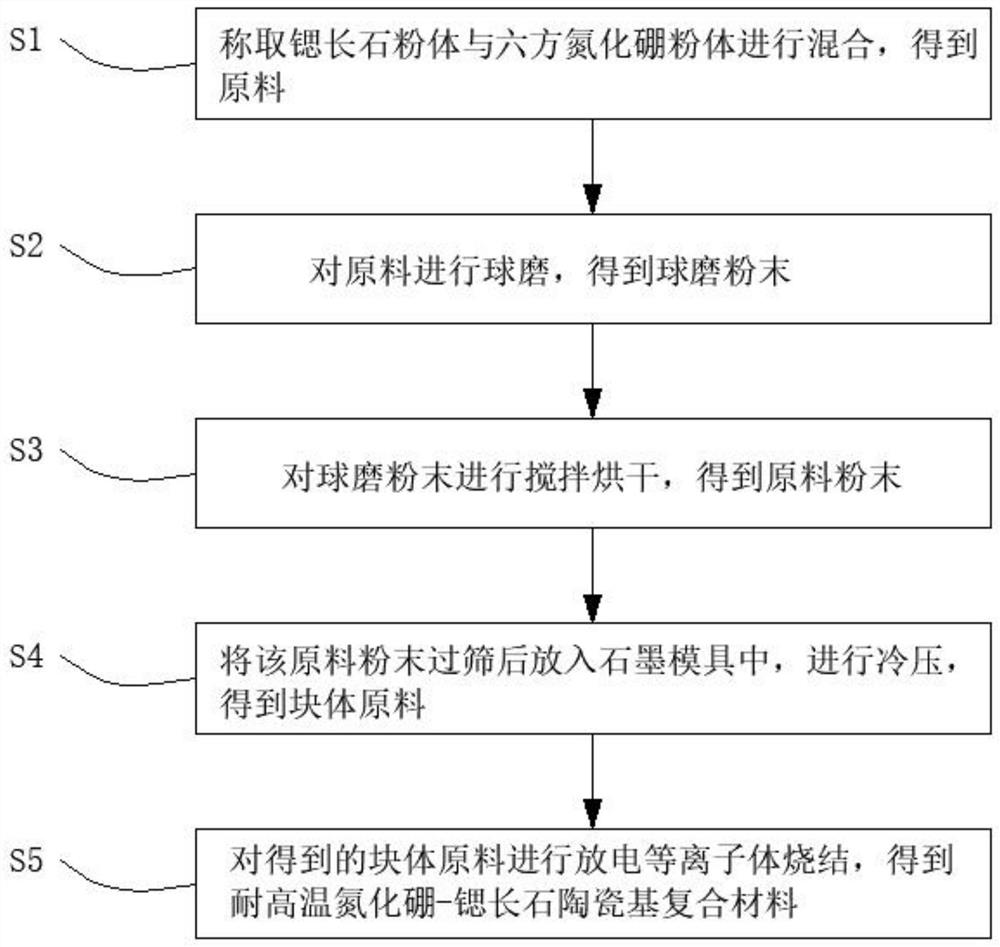

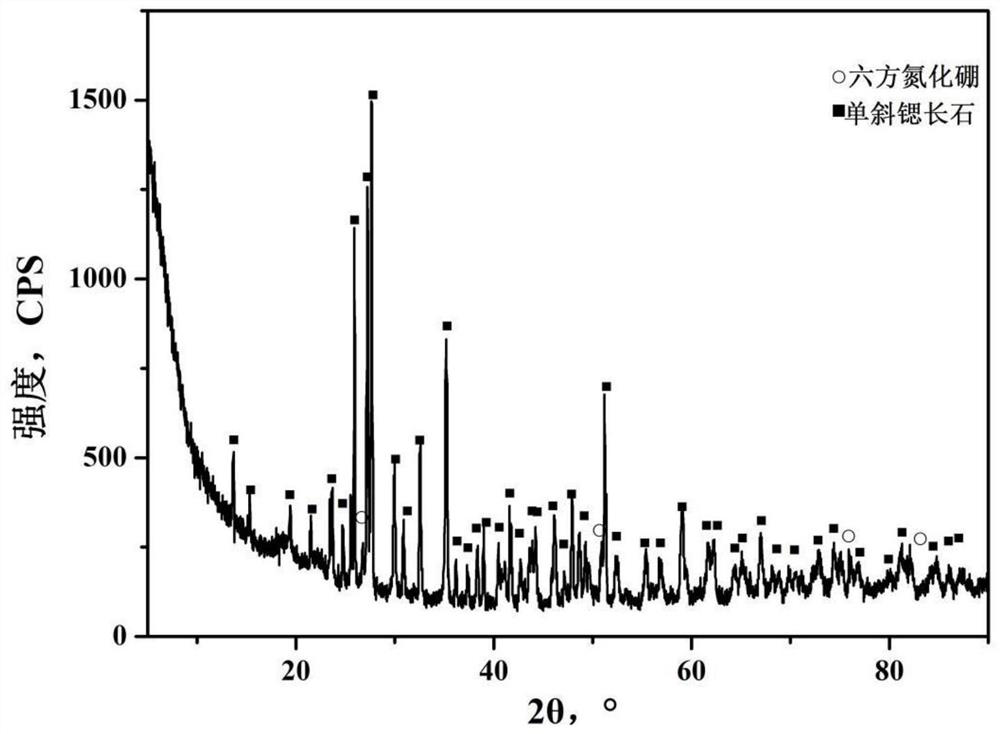

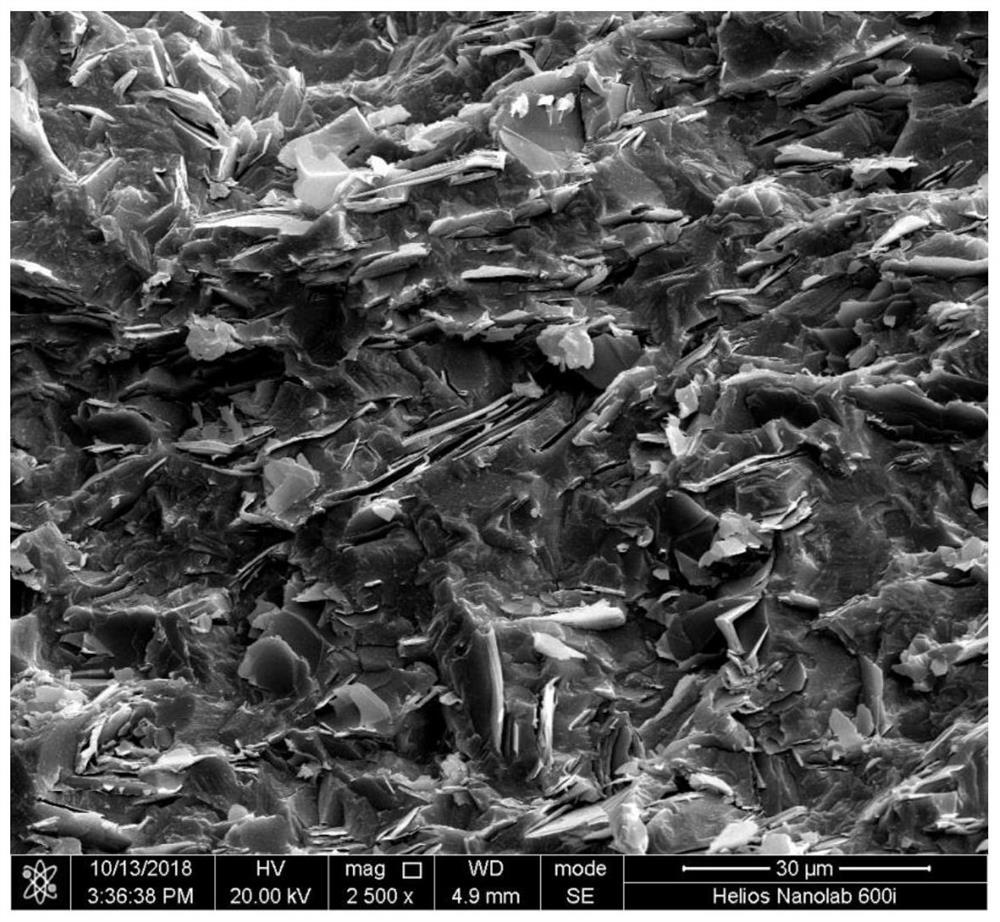

High temperature resistant boron nitride-cerium feldspar ceramic matrix composite material and preparation method thereof

ActiveCN109650862AImprove machinabilitySolve the difficulty of crystal phase regulationTemperature resistanceBall mill

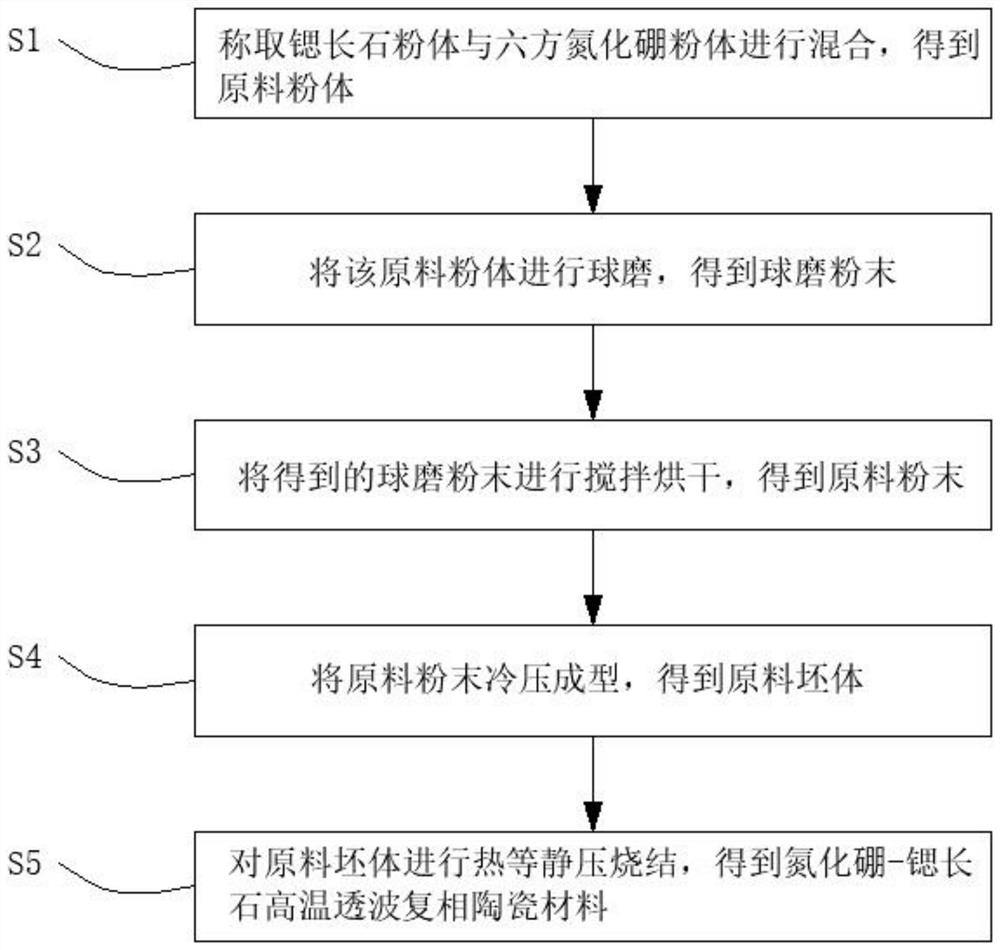

The invention discloses a high temperature resistant boron nitride-cerium feldspar ceramic matrix composite material and a preparation method thereof, and relates to the technical field of preparationof ceramic matrix composite materials. The preparation method comprises the steps of S1, weighing cerium feldspar powder to be mixed with hexagonal boron nitride powder to obtain a raw material; S2,ball-milling the raw material to obtain ball-milled powder; S3, stirring and drying the ball-milled powder to obtain raw material powder; S4, placing the raw material powder into a graphite mold, andcold-pressing is performed to obtain a bulk material; S5, performing discharge plasma sintering on the bulk material to obtain the high temperature resistant boron nitride-cerium feldspar ceramic matrix composite material. The preparation method of the high temperature resistant boron nitride-cerium feldspar ceramic matrix composite material has the advantages that the prepared boron nitride-cerium feldspar ceramic matrix composite material not only has good mechanical and processability performance by introducing boron nitride into cerium feldspar, but also has good dielectric and high temperature resistance performance.

Owner:HARBIN INST OF TECH

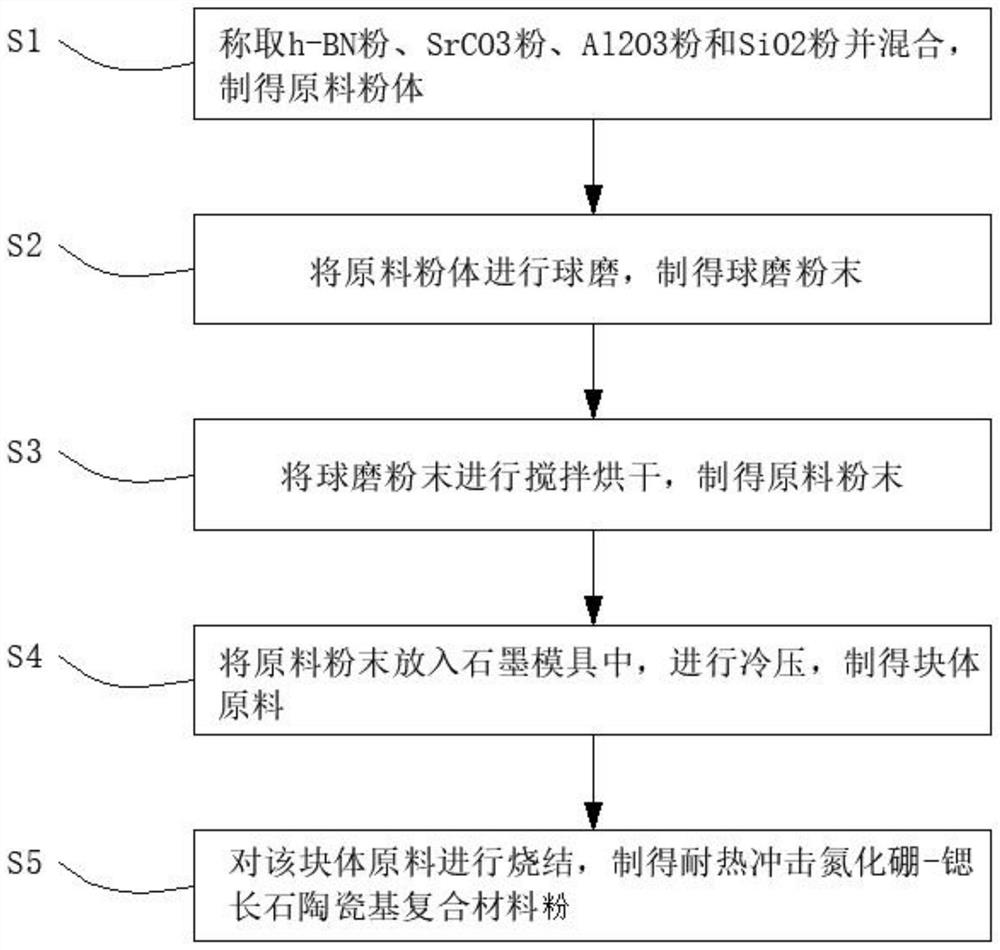

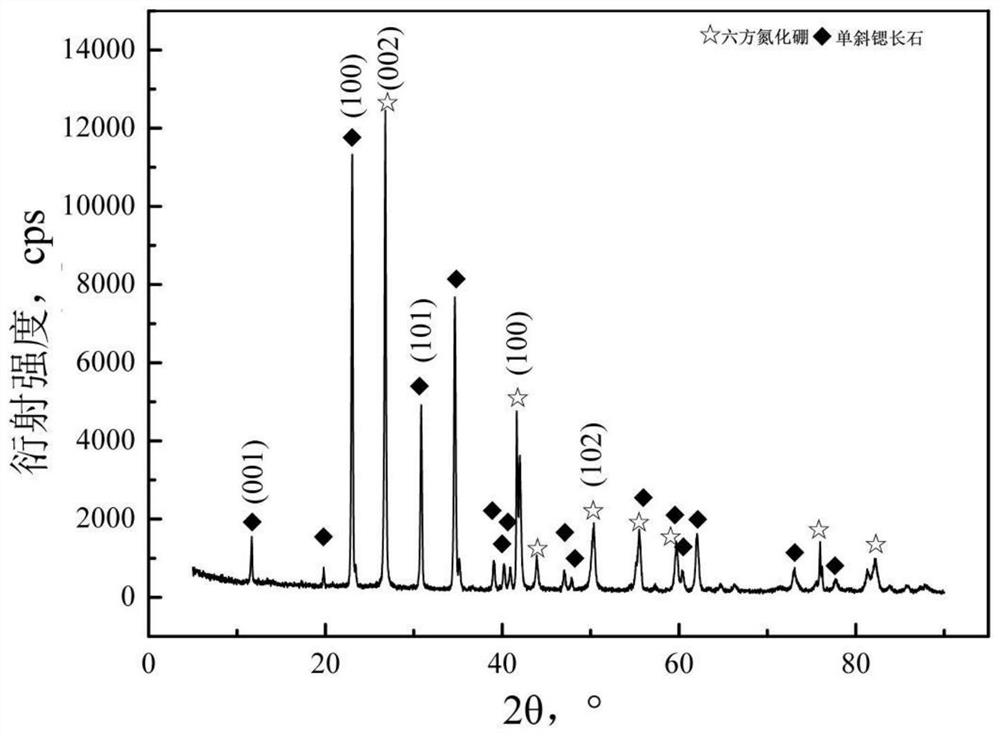

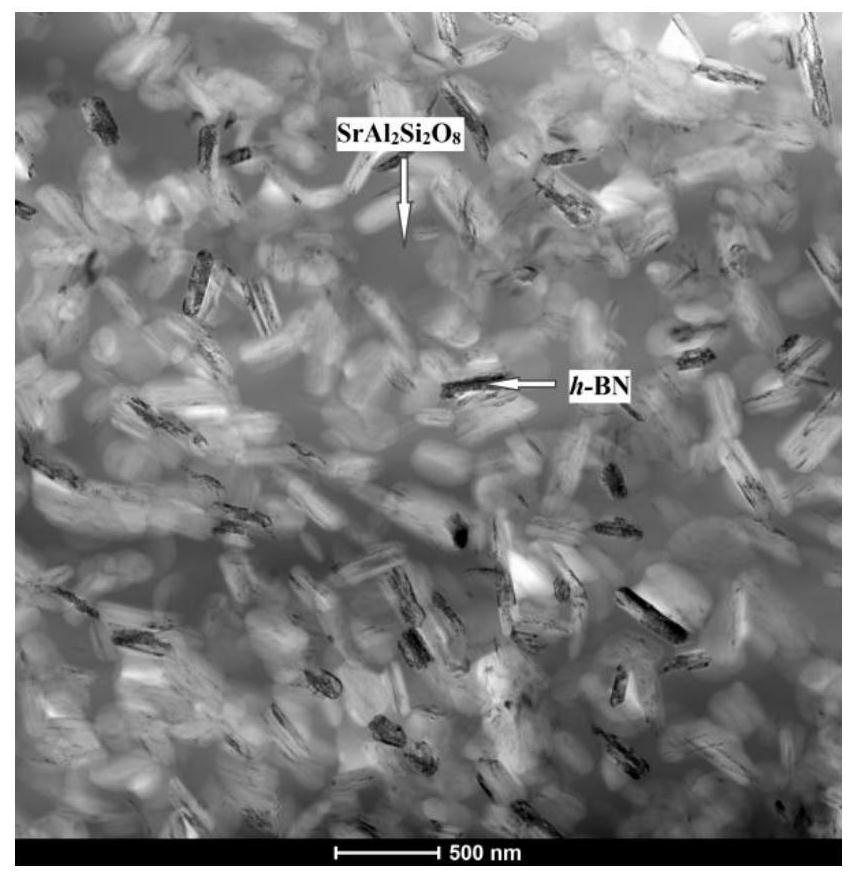

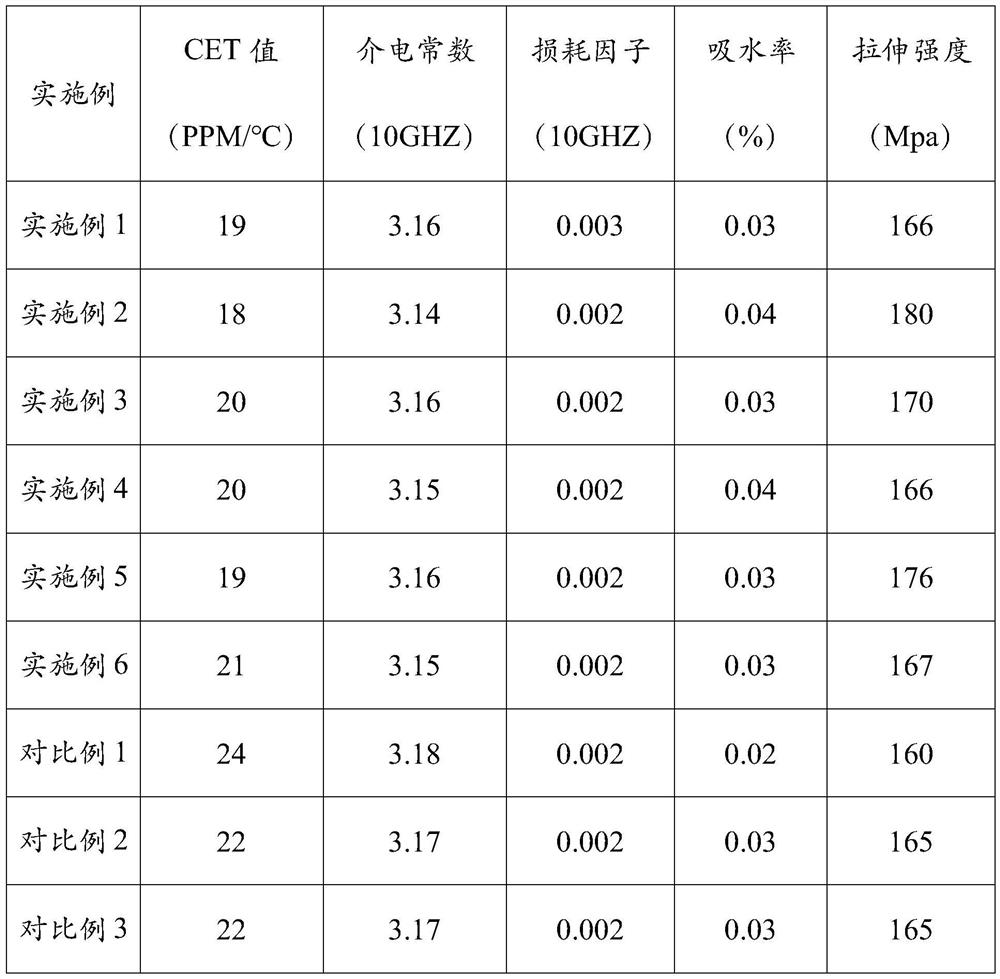

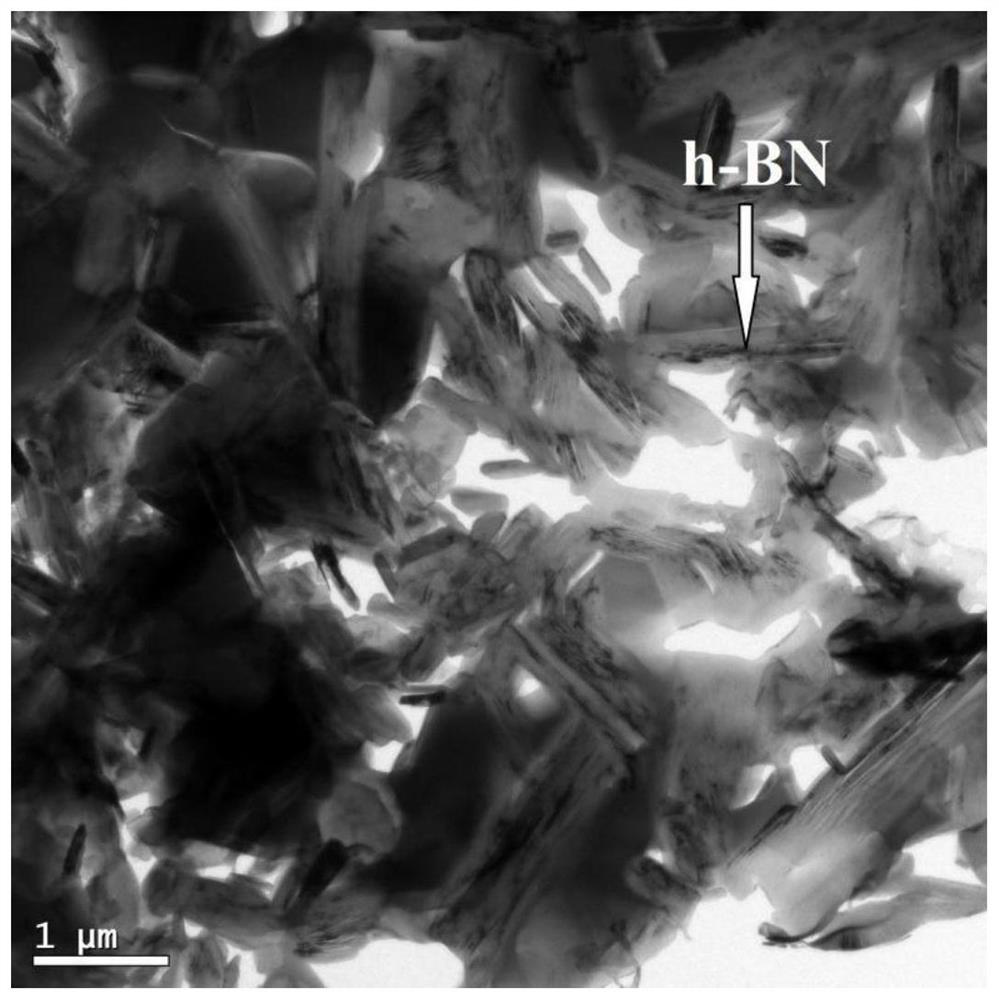

A thermal shock-resistant boron nitride-strontium feldspar ceramic matrix composite material and its preparation method

ActiveCN109704780BDoes not affect dielectric propertiesDielectric Performance GuaranteeRutheniumStrontium

The invention discloses a thermal shock-resistant boron nitride-strontium feldspar ceramic-based composite material and a preparation method thereof, and relates to the technical field of ceramic-based composite materials. The preparation method includes: S1: weighing h-BN powder, SrCO 3 Powder, Al 2 o 3 Powder and SiO 2 powder and mix to obtain a raw material powder; S2: ball mill the raw material powder to obtain a ball mill powder; S3: stir and dry the ball mill powder to obtain a raw material powder; S4: grind the raw material powder Putting it into a graphite mold and performing cold pressing to obtain a bulk raw material; S5: Sintering the bulk raw material to obtain a thermal shock-resistant boron nitride-strontium feldspar ceramic matrix composite material. The preparation method of the thermal shock-resistant boron nitride-strontium feldspar ceramic matrix composite material provided by the present invention introduces boron nitride into the strontium feldspar, and improves the strontium feldspar without affecting the dielectric properties of the strontium feldspar itself. machinability.

Owner:HARBIN INST OF TECH

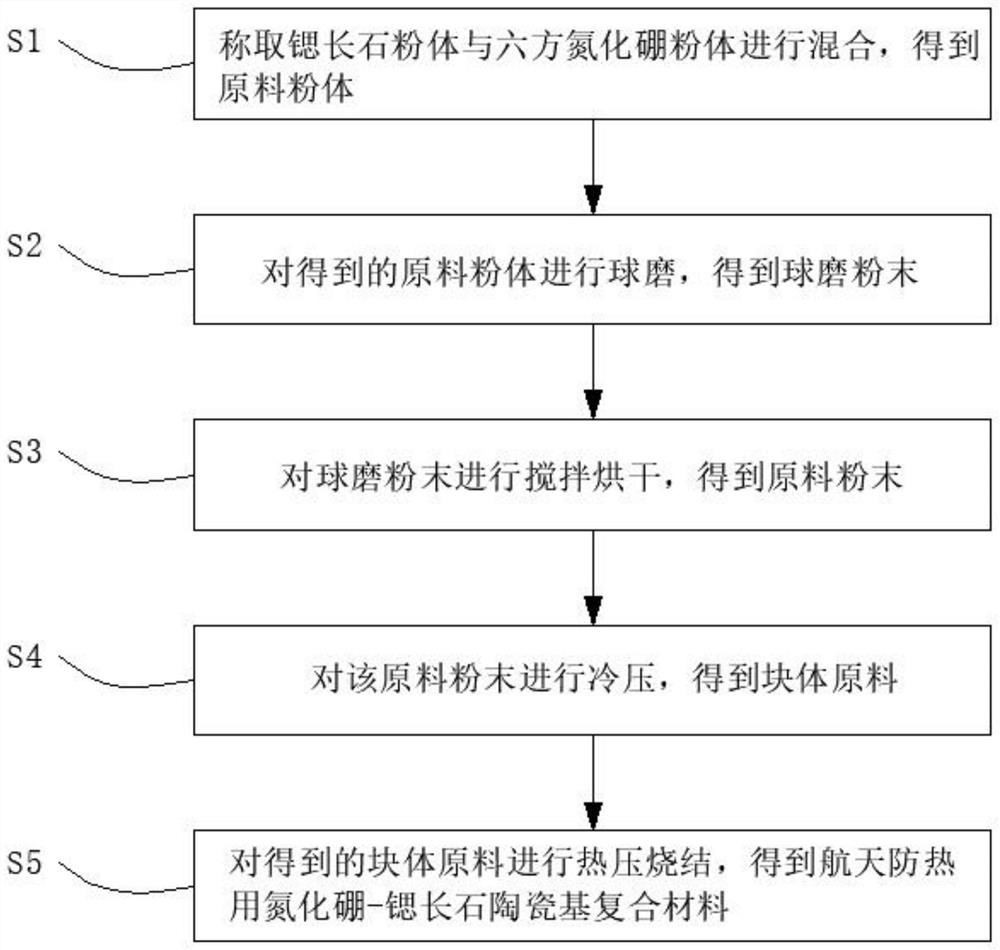

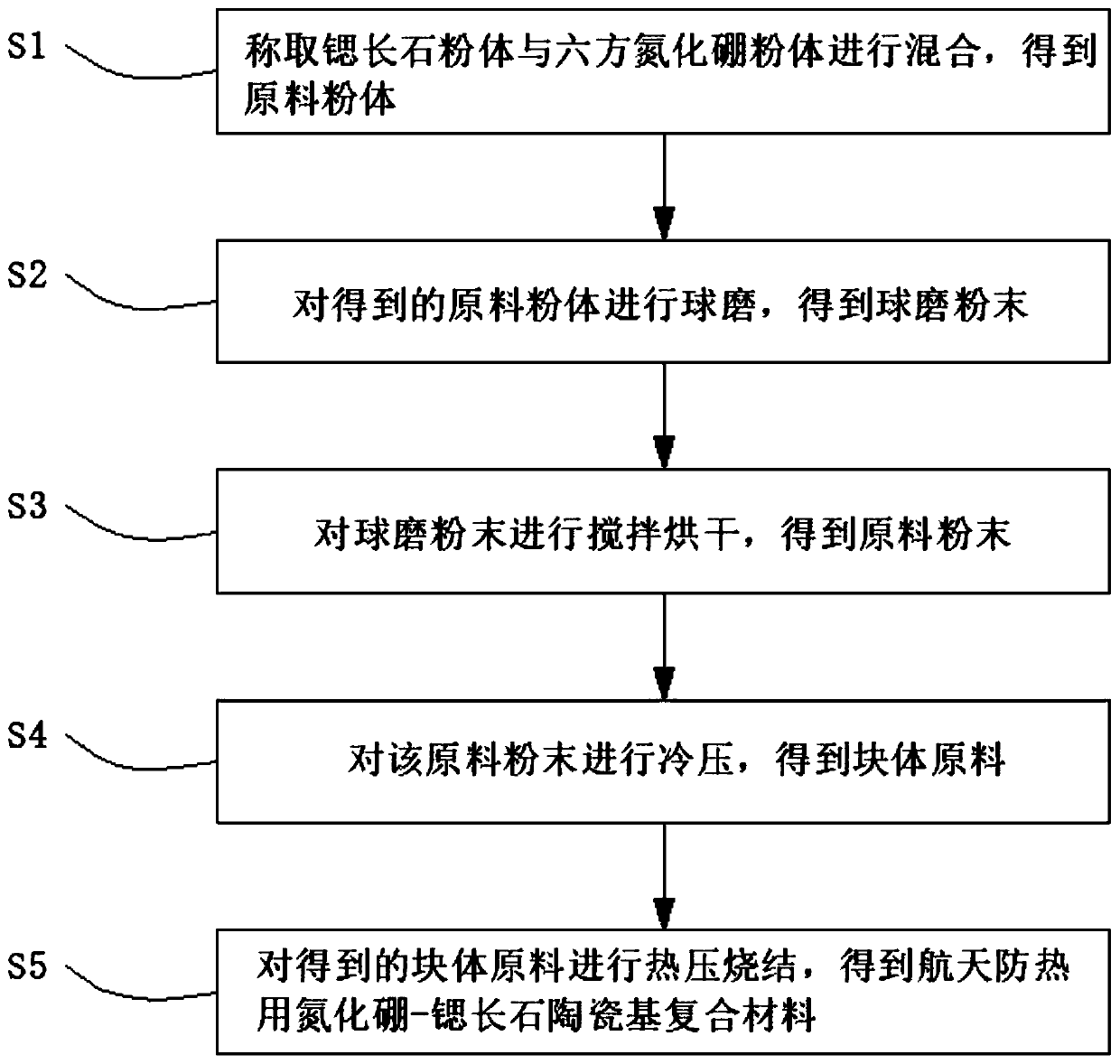

A boron nitride-strontium feldspar ceramic matrix composite material for aerospace heat protection and its preparation method

The invention discloses a boron nitride-strontium feldspar ceramic-based composite material for aerospace heat protection and a preparation method thereof, and relates to the field of preparation of ceramic-based composite materials. The preparation method of the composite material includes: S1: weighing strontium feldspar Mix the powder with hexagonal boron nitride powder to obtain a raw material powder; S2: ball mill the raw material powder to obtain a ball milled powder; S3: stir and dry the ball milled powder to obtain a raw material powder; S4: Cold pressing the raw material powder to obtain a block raw material; S5: hot pressing and sintering the block raw material to obtain a boron nitride-strontium feldspar ceramic matrix composite material for aerospace heat protection. The preparation method of the boron nitride-strontium feldspar ceramic-based composite material for aerospace heat protection provided by the present invention makes the prepared boron nitride-strontium feldspar ceramic-based composite material ensure the dielectric properties of the boron nitride-strontium feldspar Strontium feldspar ceramic matrix composites have good mechanical properties and machinability.

Owner:HARBIN INST OF TECH

A kind of thermosetting resin composition and prepreg and laminate made by using the same

ActiveCN106243626BGood compatibilityImprove interface performanceSynthetic resin layered productsElectrical equipmentEpoxyImide

The present invention discloses a thermosetting resin composition, which comprises (calculated as the solid weight): (a) 10-80 parts of a hydrocarbon resin, (b) 20-100 parts of maleimide ester, (c) 0.1-8 parts of an initiator, and (d) 5-100 parts of an epoxy resin. According to the present invention, the maleimide ester having the polyfunctional long-chain structure and the rigid imide ring is used and is matched with the hydrocarbon resin having the flexibility to form the thermosetting composition, such that the thermosetting resin composition and the prepared printed circuit prepreg and laminated plate produced by using thermosetting resin composition have characteristics of excellent dielectric property, excellent heat resistance, excellent adhesion, excellent flame retardancy, excellent flexural strength, excellent toughness, high peel strength, low water absorption, excellent processability and the like through the interaction between the hydrocarbon resin and the maleimide ester.

Owner:SHENGYI TECH SUZHOU

Boron nitride-strontium feldspar ceramic-based composite material for aerospace heat protection and preparation method of composite material

The invention discloses a boron nitride-strontium feldspar ceramic-based composite material for aerospace heat protection and a preparation method of the composite material, and relates to the field of ceramic-based composite materials. The preparation method of the composite material includes the steps: S1 weighing and mixing strontium feldspar powder and hexagonal boron nitride powder to obtainraw material powder; S2 ball-milling the raw material powder to obtain ball-milled powder; S3 stirring and drying the ball-milled powder to obtain raw material powder; S4 cold-pressing the raw material powder to obtain bulk raw materials; S5 hot-pressing and sintering the bulk raw materials to obtain the boron nitride-strontium feldspar ceramic-based composite material for aerospace heat protection. According to the preparation method of the boron nitride-strontium feldspar ceramic-based composite material for aerospace heat protection, on the premise of ensuring the dielectric property of theboron nitride-strontium feldspar ceramic-based composite material, the prepared boron nitride-strontium feldspar ceramic-based composite material has good mechanical and machinable properties.

Owner:HARBIN INST OF TECH

A modified polybutadiene prepolymer and its preparation method and application

ActiveCN107033517BImprove heat resistanceImprove toughnessSynthetic resin layered productsElectrical equipmentImidePolymer science

The invention relates to a modified polybutadiene prepolymer as well as a preparation method and application thereof, resin composition prepared from the modified polybutadiene prepolymer, a prepreg prepared from the resin composition, a metal foil coated laminated board and a layer insulation film. The modified polybutadiene prepolymer is a prepolymer of an epoxy polybutadiene mixture, bismaleimide resin and cyanate ester in the weight ratio being 100: (10-60): (15-80). The problem that polybutadiene is incompatible with other resin is solved, the adhesion performance of a hydrocarbon resin system is improved, the peel strength between copper foil of the laminated board and the resin layer is improved, and the dielectric performance of the resin system is not affected. The brittleness of a maleimide cured product is improved by the aid of epoxy polybutadiene resin, polybutadiene and silica-containing butadiene.

Owner:SHENGYI TECH SUZHOU

Low-temperature co-fired ceramic material emitting white light and preparation method thereof

The invention provides a low-temperature co-fired ceramic material emitting white light and a preparation method thereof. The ceramic material comprises the following components in percentage by mol: 10 to 20 percent of CaO, 20 to 30 percent of B2O3, 50 to 60 percent of SiO2, and 1 to 9 percent of optical activating agent ions. The invention also relates to the preparation method of the material, namely, a sol-gel method for preparing the low-temperature co-fired ceramic material emitting white light. The invention has the advantages that: 1, the preparation process is simple and advanced, the sintering temperature is low by adopting the Sol-gel method and is between 800 DEG C and 900 DEG C, the sintering shrink rate at the temperature is controllable between 13 percent and 17 percent, and a glass ceramic material has a flat and smooth surface, as well as higher strength; 2, the dielectric constant is adjustable between 4(1MHz) and 6 (1MHz), and the coefficient of dielectric loss is lower than 0.002; 3, the light emission intensity is high, the material can emit yellow and blue light under activation of ultraviolet light with the wavelength of between 320nm and 410nm, the white light obtained by mixing the blue light and the yellow light can be used for illuminating and displaying; and 4, based on the advantages, the low-temperature co-fired ceramic material can be applied to the fields of white light LED (Light Emitting Diode) lamps, integrated ceramic substrates and other electronic devices and semiconductors, as well as microelectronic packaging materials.

Owner:UNIV OF SCI & TECH BEIJING

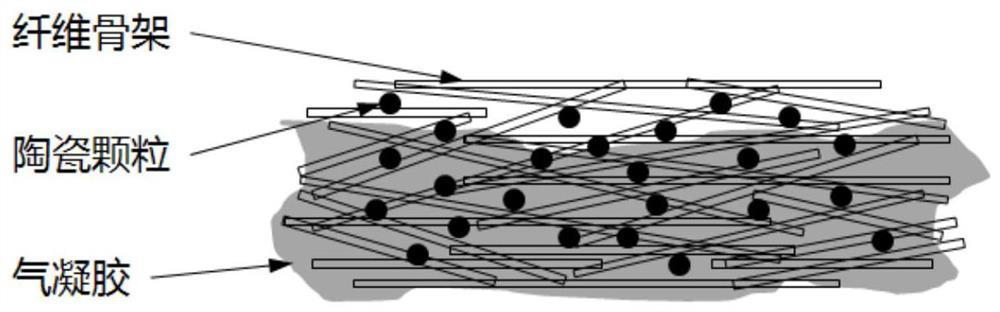

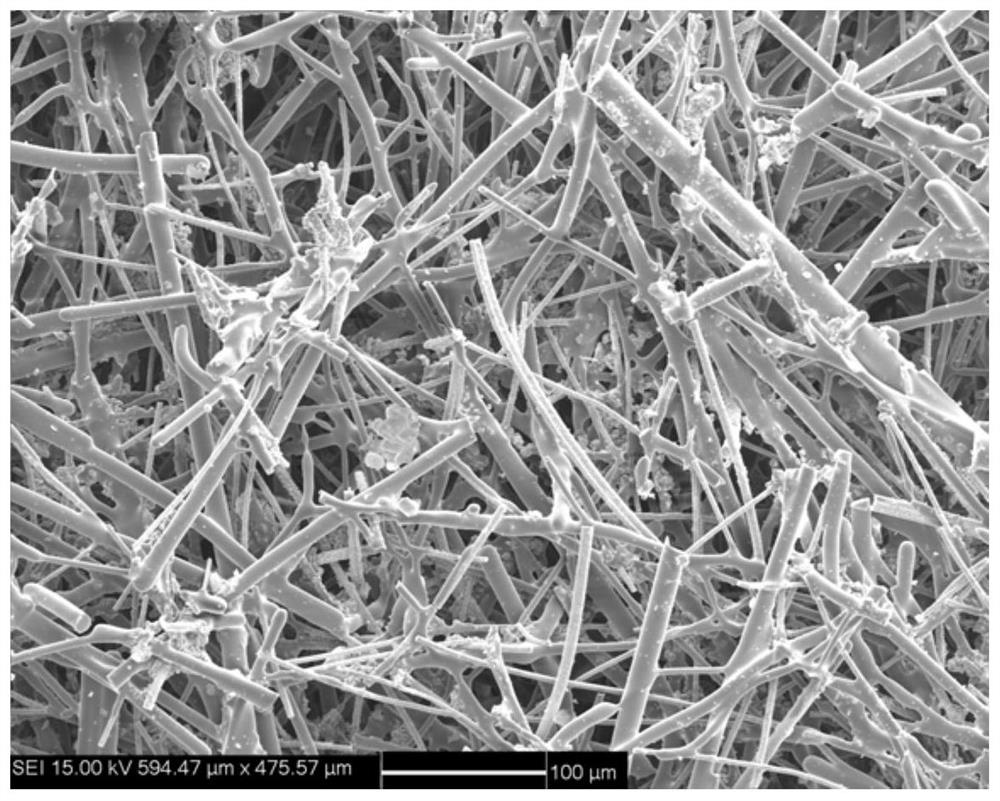

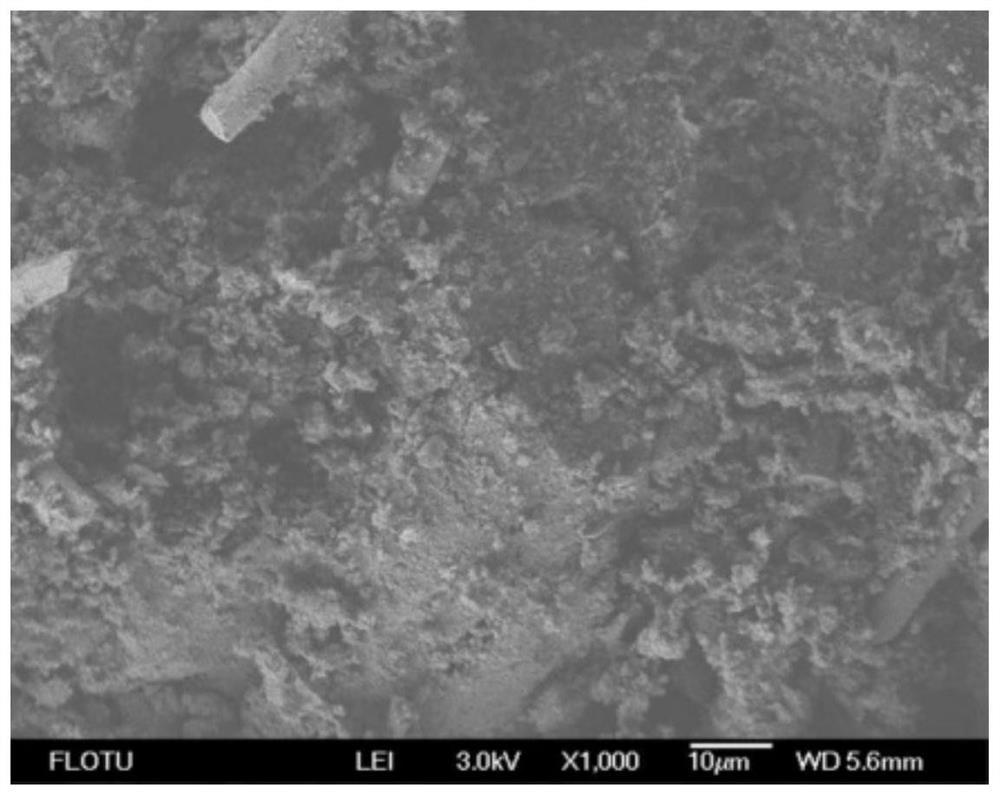

A high-temperature-resistant, heat-insulating, wave-transmitting functional integrated composite material and its preparation method

The invention relates to a high-temperature-resistant, heat-insulating and wave-transmitting function integrated composite material and a preparation method thereof, belonging to the technical field of inorganic materials. The prepared high-temperature-resistant, heat-insulating and wave-transmitting material has high temperature resistance, high strength, low thermal conductivity, and transparent The characteristics of good wave performance. The high-temperature-resistant, heat-insulating and wave-transmitting function integrated composite material composite material obtained in the present invention has a multi-layer structure in the thickness direction, the high-temperature layer is a fiber skeleton and ceramic particles, and the low-temperature layer is a fiber skeleton, ceramic particles and airgel, and each layer The thickness can be determined according to specific design requirements.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

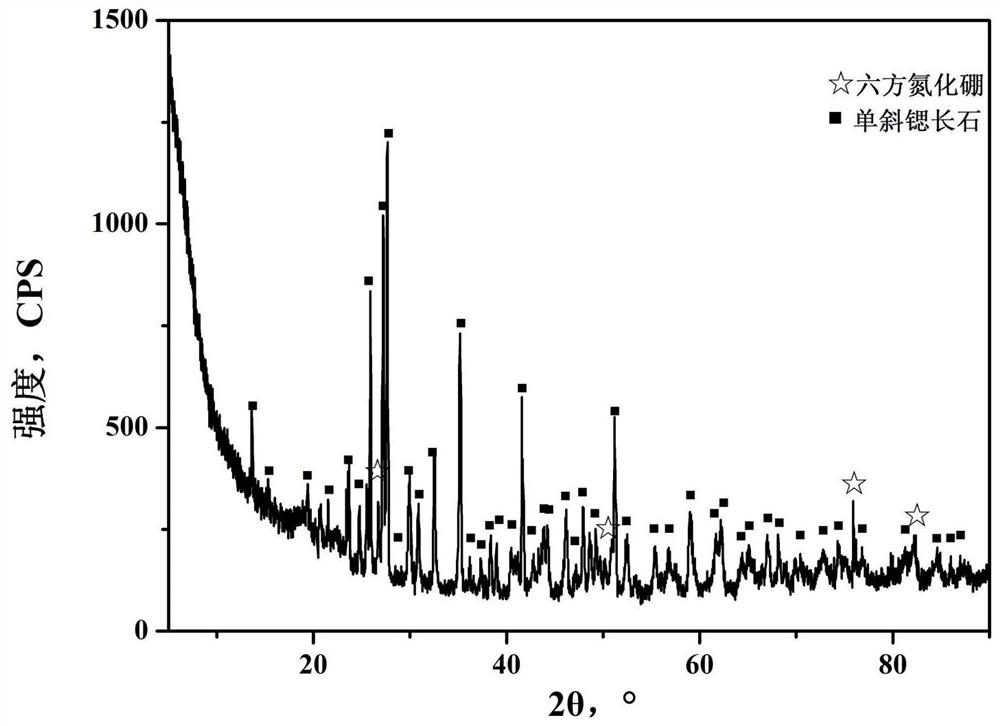

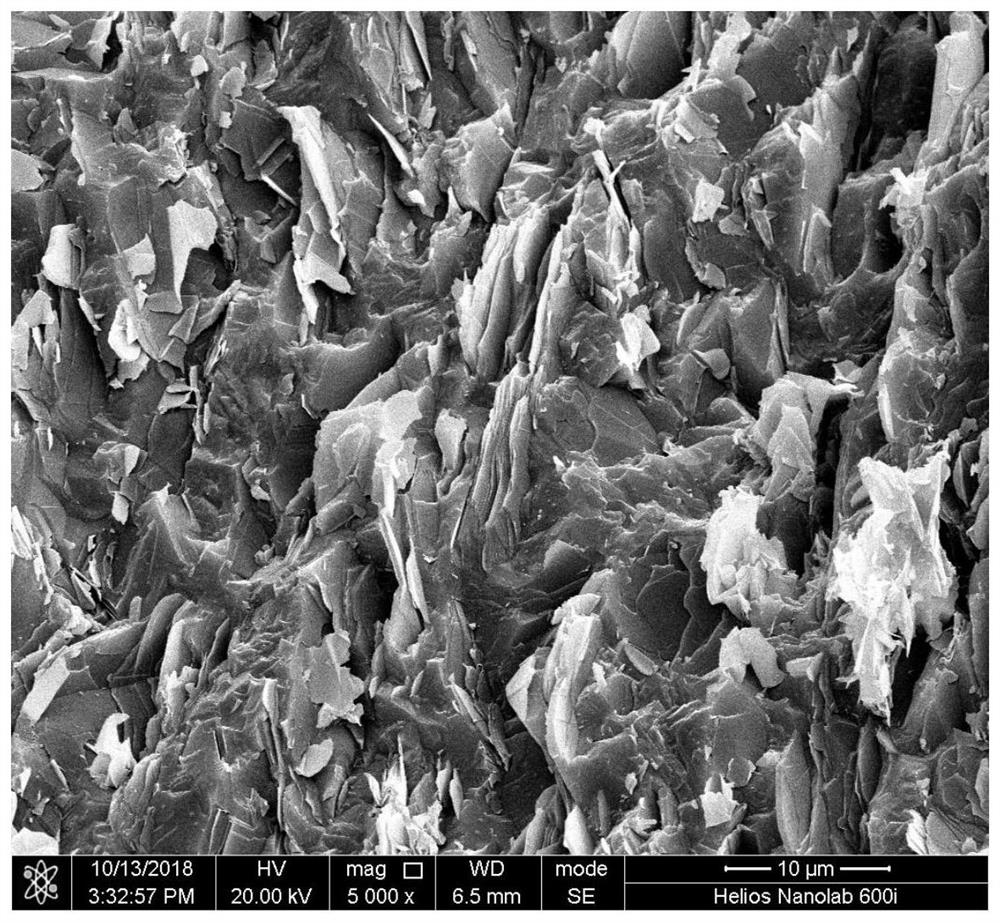

Boron nitride-strontium feldspar high-temperature wave-transparent composite ceramic material and preparation method thereof

ActiveCN109650863BDoes not affect dielectric propertiesDielectric Performance GuaranteeHexagonal boron nitrideRuthenium

The invention discloses a boron nitride-strontium feldspar high-temperature wave-transparent composite phase ceramic material and a preparation method thereof, and relates to the field of preparation of ceramic matrix composite materials. The boron nitride-strontium feldspar high-temperature wave-transparent composite phase ceramic material The preparation method includes: S1: weighing strontium feldspar powder and mixing hexagonal boron nitride powder to obtain raw material powder; S2: ball milling the raw material powder to obtain ball milling powder; S3: ball milling the powder Stirring and drying to obtain raw material powder; S4: cold pressing the raw material powder to obtain a raw material green body; S5: performing hot isostatic sintering on the raw material green body to obtain boron nitride-strontium feldspar high-temperature transparent Wave complex phase ceramic materials. The preparation method of boron nitride-strontium feldspar high-temperature wave-transparent composite ceramic material provided by the present invention introduces hexagonal boron nitride into strontium feldspar, so that the prepared composite ceramic material not only has good machinability, but also It has good dielectric and high temperature resistance properties.

Owner:HARBIN INST OF TECH

A kind of thermosetting resin composition and prepreg and laminate made by using the same

ActiveCN106221126BImprove toughnessImprove heat resistanceSynthetic resin layered productsLaminationImidePolymer science

Owner:SHENGYI TECH SUZHOU

Liquid crystal polymer composite material and preparation method thereof

The invention discloses a liquid crystal polymer composite material and a preparation method thereof. The preparation method comprises the following steps of: (1) mixing a liquid crystal copolymer, a polyester polymer and an additive to obtain a mixed base material; and (2) melting and mixing the mixed base material in a co-rotating twin-screw extruder, and extruding and granulating to obtain the liquid crystal polymer composite material. The mixed base material is prepared from the following components in parts by weight: 50-90 parts of the liquid crystal copolymer; 5-30 parts of the polyester polymer; and 5-20 parts of the additive. According to the invention, the polyesterpolymer and the additive with similar structures are introduced into the liquid crystal copolymer, so that the mechanical properties of the liquid crystal copolymer are improved while the original dielectric properties of the liquid crystal copolymer are not influenced, the viscosity of the liquid crystal polymer can be improved, and the liquid crystal polymer can form a film more easily. The preparation method is simple in process and high in processability.

Owner:NINGXIA QINGYAN POLYMER MATERIALS CO LTD

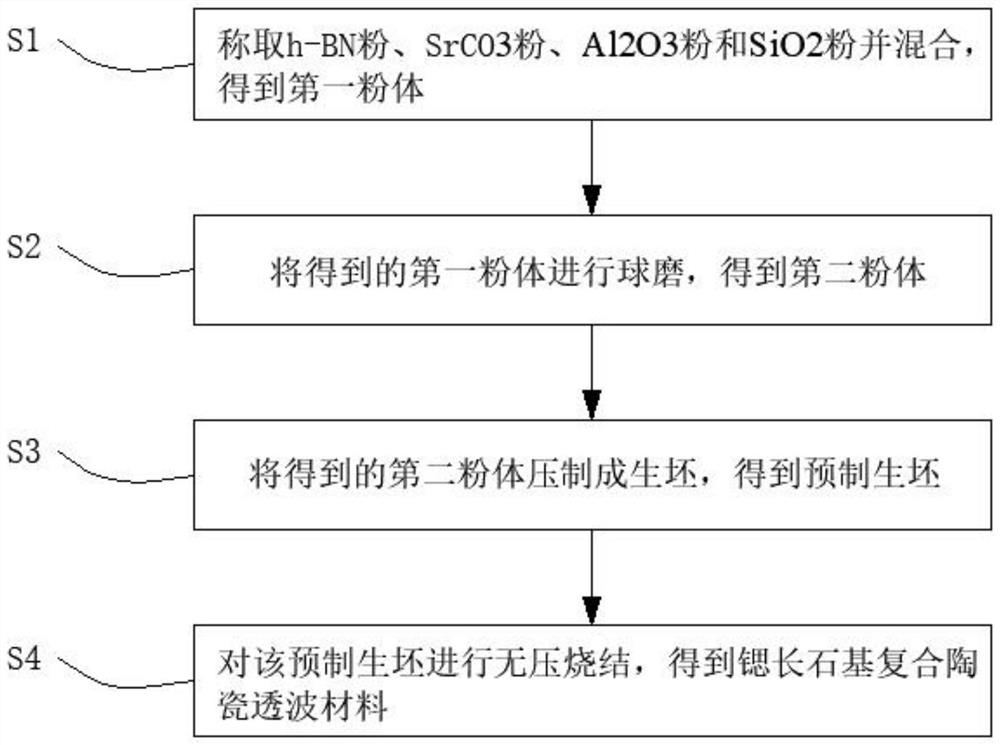

Strontium feldspar based composite ceramic wave-transmitting material and preparation method thereof

ActiveCN109650864BDoes not affect dielectric propertiesDielectric Performance GuaranteeComposite ceramicBall mill

The invention discloses a strontium feldspar-based composite ceramic wave-transparent material and a preparation method thereof, and relates to the technical field of preparation of ceramic-based composite materials. The preparation method of the strontium feldspar-based composite ceramic wave-transparent material includes: S1: weighing h ‑BN powder, SrCO 3 Powder, Al 2 o 3 Powder and SiO 2 powder and mix to obtain a first powder; S2: ball mill the first powder to obtain a second powder; S3: press the second powder into a green body to obtain a prefabricated green body; S4: The prefabricated green body is subjected to pressureless sintering to obtain a strontium feldspar-based composite ceramic wave-transmitting material. The preparation method of strontium feldspar-based composite ceramic wave-transparent material provided by the present invention introduces h-BN into strontium feldspar through in-situ synthesis reaction, so that the prepared strontium feldspar-based composite ceramic wave-transparent material not only has good mechanical properties And machinability, at the same time, also has good dielectric and thermal shock resistance.

Owner:HARBIN INST OF TECH

A kind of thermosetting resin composition and prepreg and laminated board prepared by using it

ActiveCN109943047BImprove heat resistanceHigh mechanical strengthSynthetic resin layered productsMetal layered productsEpoxyPolyester

The invention discloses a thermosetting resin composition, which comprises, in parts by weight: (a) epoxy resin: 100 parts; (b) unsaturated polyester active ester resin: 50-200 parts; (c) vinyl modified Permanent polyphenylene ether resin: 10~200 parts; (d) Accelerator: 0.05~4 parts. The unsaturated polyester active ester resin of the present invention can effectively combine the active ester curing epoxy resin system, the hydrocarbon resin curing system and the polyphenylene ether resin system through chemical bonds, and combine the excellent properties of the active ester curing epoxy system , The excellent performance of hydrocarbon resin and the excellent performance of polyphenylene ether resin system are effectively combined, so that the resin composition has excellent dielectric properties, heat resistance, strength, rigidity and flexibility, high peel strength and water absorption after curing. Low heat shrinkage rate, can be applied to high-speed, high-frequency printed circuit boards.

Owner:SHENGYI TECH SUZHOU

A kind of thermosetting resin composition and prepreg and laminated board made of it

ActiveCN106349643BImprove toughnessImprove rigiditySynthetic resin layered productsLaminationImideHeat resistance

The invention discloses a thermosetting resin composition. The thermosetting resin composition is prepared from, by solid weight: (a) 10-100 parts of hydrocarbon resin; (b) 20-100 parts of maleimide; (c) 0.1-8 parts of initiator; (d) 10-100 parts of cyanate ester resin. The thermosetting resin composition applies the maleimide with multi-functional long-chain structure and rigid imide ring and combines with a flexible hydrocarbon resin to form a thermosetting composition through the interaction, and finally makes the thermosetting resin composition and prepregs and laminates produced by using the same for the printed circuit have the characteristics of excellent dielectrical property, heat resistance, adhesion, flame resistance, bending strength, toughness, high peel strength, low water absorption, excellent processing performance and others.

Owner:SHENGYI TECH SUZHOU

A high temperature resistant boron nitride-strontium feldspar ceramic matrix composite material and its preparation method

The invention discloses a high-temperature-resistant boron nitride-strontium feldspar ceramic-based composite material and a preparation method thereof, and relates to the technical field of preparation of ceramic-based composite materials. The preparation method includes: S1: weighing strontium feldspar powder and hexagonal Boron nitride powders are mixed to obtain raw materials; S2: ball mill the raw materials to obtain ball milled powders; S3: stir and dry the ball milled powders to obtain raw material powders; S4: put the raw material powders into graphite In the mold, cold pressing is carried out to obtain a block raw material; S5: performing discharge plasma sintering on the block raw material to obtain a high-temperature resistant boron nitride-strontium feldspar ceramic matrix composite material. The preparation method of the high-temperature-resistant boron nitride-strontium feldspar ceramic-based composite material provided by the present invention introduces boron nitride into strontium feldspar, so that the prepared boron nitride-strontium feldspar ceramic-based composite material not only has good Mechanical and machinable properties, at the same time, it also has good dielectric and high temperature resistance properties.

Owner:HARBIN INST OF TECH

A kind of thermosetting resin composition and prepreg and laminated board prepared by using it

ActiveCN109867912BImprove heat resistanceHigh mechanical strengthMetal layered productsEpoxyPolyester

The invention discloses a thermosetting resin composition, which comprises, in parts by weight: (a) epoxy resin: 100 parts; (b) unsaturated polyester active ester resin: 50-200 parts; (c) vinylbenzyl Base modified phenolic resin: 10~200 parts; (d) Accelerator: 0.05~4 parts. The unsaturated polyester active ester resin of the present invention can effectively combine the active ester curing epoxy resin system, the hydrocarbon resin curing system and the vinyl benzyl modified phenolic resin system through chemical bonds, and the active ester curing epoxy resin The excellent performance of the system, the excellent performance of the hydrocarbon resin and the excellent performance of the vinyl benzyl modified phenolic resin system are effectively combined, so that the resin composition has excellent dielectric properties, heat resistance, strength, rigidity after curing. Flexible, high peel strength, low water absorption, small thermal shrinkage, can be applied to high-speed, high-frequency printed circuit boards.

Owner:SHENGYI TECH SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com