High-strength high-modulus low-dielectric constant fiberglass

A glass fiber and dielectric constant technology, applied in the field of high-strength, high-modulus, and low-dielectric constant glass fibers, can solve the problems of poor water resistance and low mechanical properties of glass fibers, and improve strength, modulus, and manufacturability. and the effect of moderate operability and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1--14

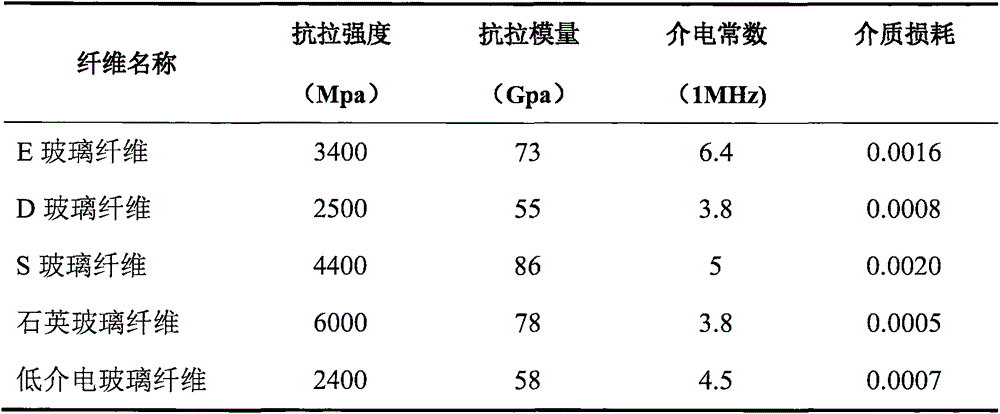

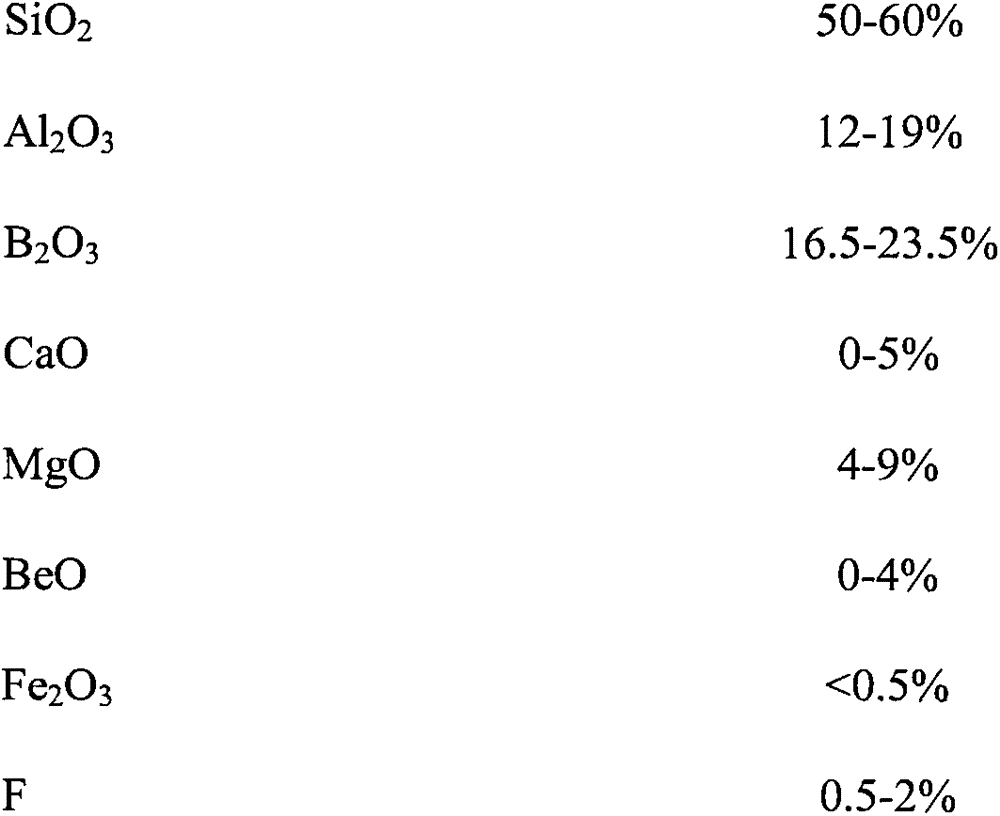

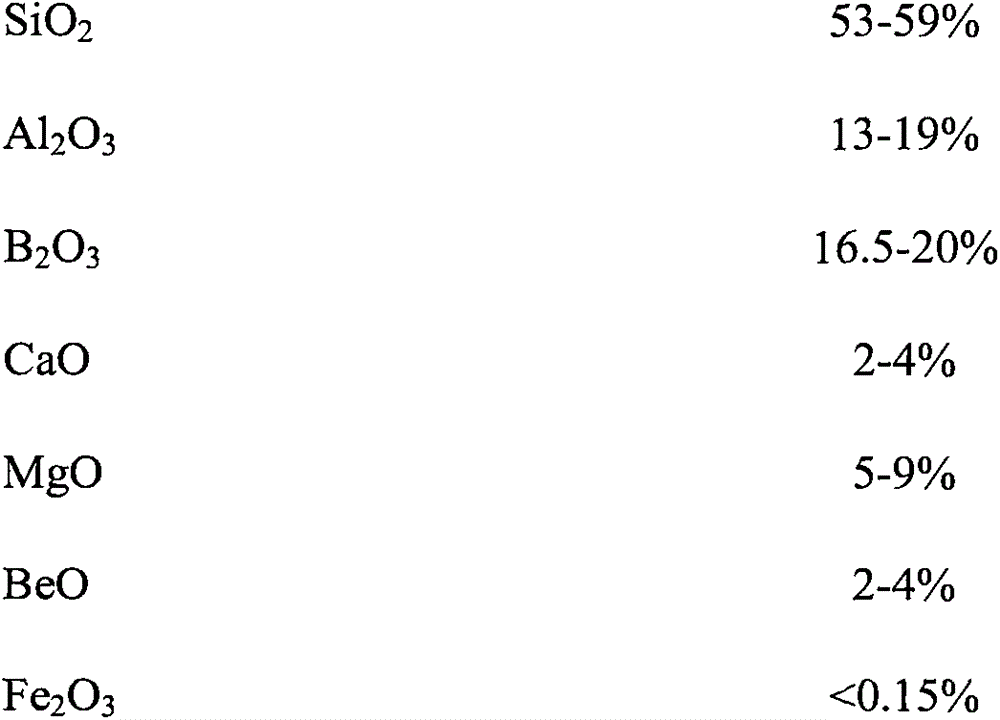

[0030] Prepare batch materials in the laboratory according to the formulas in Table (2) and Table (3), melt glass and prepare low-dielectric glass fibers, and perform performance testing (testing conditions are as remarked), and the performance is as follows:

[0031] The preparation method of each embodiment glass fiber in table (two) and table (three) is: 1) prepare according to the composition or mole percentage described in table (two) and table (three), after raw material is mixed evenly, by zirconia material and Heating to 1500-1580°C in a kiln built with chromium oxide materials to ensure that all raw materials are melted, clarified and defoamed for 24 hours, pass the clarified glass liquid through a 1000-hole platinum / rhodium alloy drain plate, and use a TL300 glass fiber drawing machine For fiber forming, the bushing temperature is adjustable at 1250-1400°C, the rotation speed of the wire drawing machine is adjustable at 2100-2800 rpm, and the diameter of the obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com