Insulation extrusion equipment for cable production

An extrusion equipment and cable extrusion technology, which is applied in applications, household appliances, household components, etc., can solve the problems that the extruder does not have the function of breaking cable materials, lacks the preheating function, and unfavorable extrusion efficiency, etc., and achieves a reduction Melting difficulty, improved mixing effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

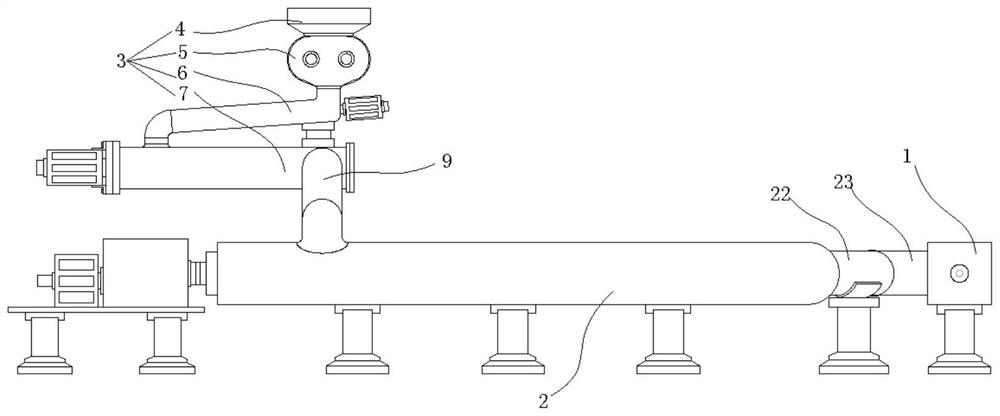

[0029] An insulation extrusion equipment for cable production, including an extruder head 1 for cable extrusion, characterized in that, one side of the extruder head 1 is provided with an extruding and plasticizing mechanism 2 for supplying molten cable material , the number of the extruding and plasticizing mechanism 2 is multiple, at least 2, and its upper end is provided with a feeding mechanism 3 for supplying cable materials.

[0030] In this embodiment, the cable material is fed by the feeding mechanism, enters the extrusion plasticizing mechanism, plasticizes and melts, and finally enters the extruder head to extrude the cable (inner conductor).

Embodiment 2

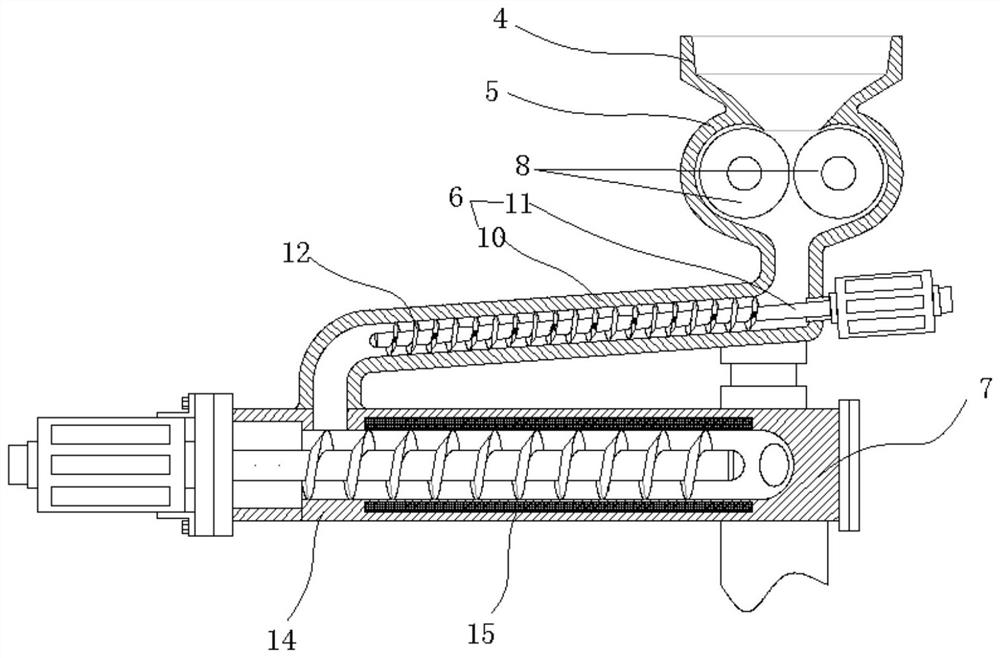

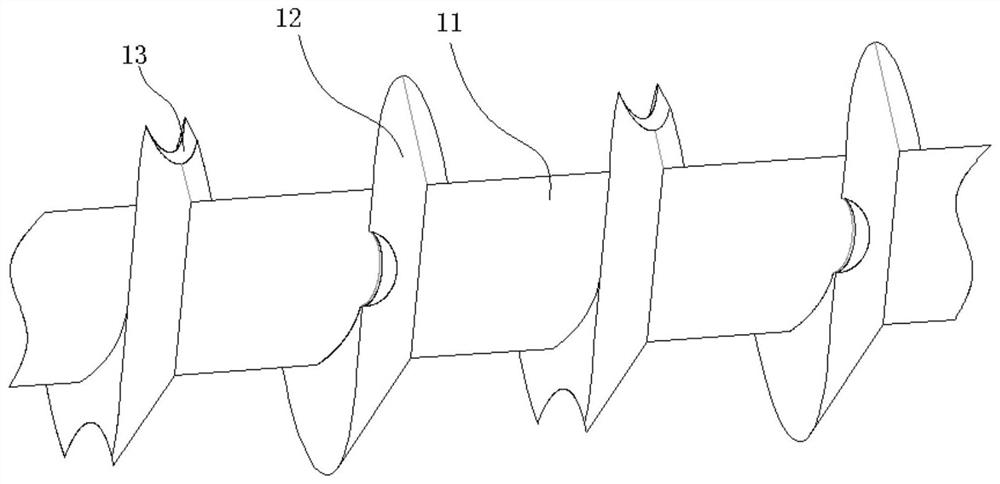

[0032] Insulation extrusion equipment for cable production in this embodiment, wherein the unloading mechanism 3 includes a hopper 4, a crushing and crushing assembly 5, a first feeding device 6 and a second feeding device 7, and the crushing and crushing assembly 5 is arranged directly below the hopper 4, its upper end communicates with the hopper 4, and its lower end communicates with the upper end of the first feeding device 6. The crushing and crushing assembly 5 is provided with two crushing rollers 8 that are squeezed against each other. The rolling roller 8 is arranged horizontally and symmetrically, and is controlled by a motor to rotate. The first feeding device 6 is a feeding auger, which is arranged obliquely. The upper end of the first feeding device 6 is the feeding end, and the lower end is the discharging end. Its upper end communicates with the rolling and crushing assembly 5, and its lower end communicates with the second feeding device 7. The second feeding de...

Embodiment 3

[0035] In the insulation extrusion equipment for cable production in this embodiment, the rotation directions of the two rolling rollers 8 are opposite, which is convenient for extrusion rolling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com