Glass composition, alumina silicate glass and preparation method and application of glass composition

A technology of aluminosilicate glass and glass composition, applied in the field of glass manufacturing, can solve the problems of long melting temperature or melting time, difficulty in melting and clarifying at high temperature, increase energy consumption and production cost, etc. Production cost reduction, effect of production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

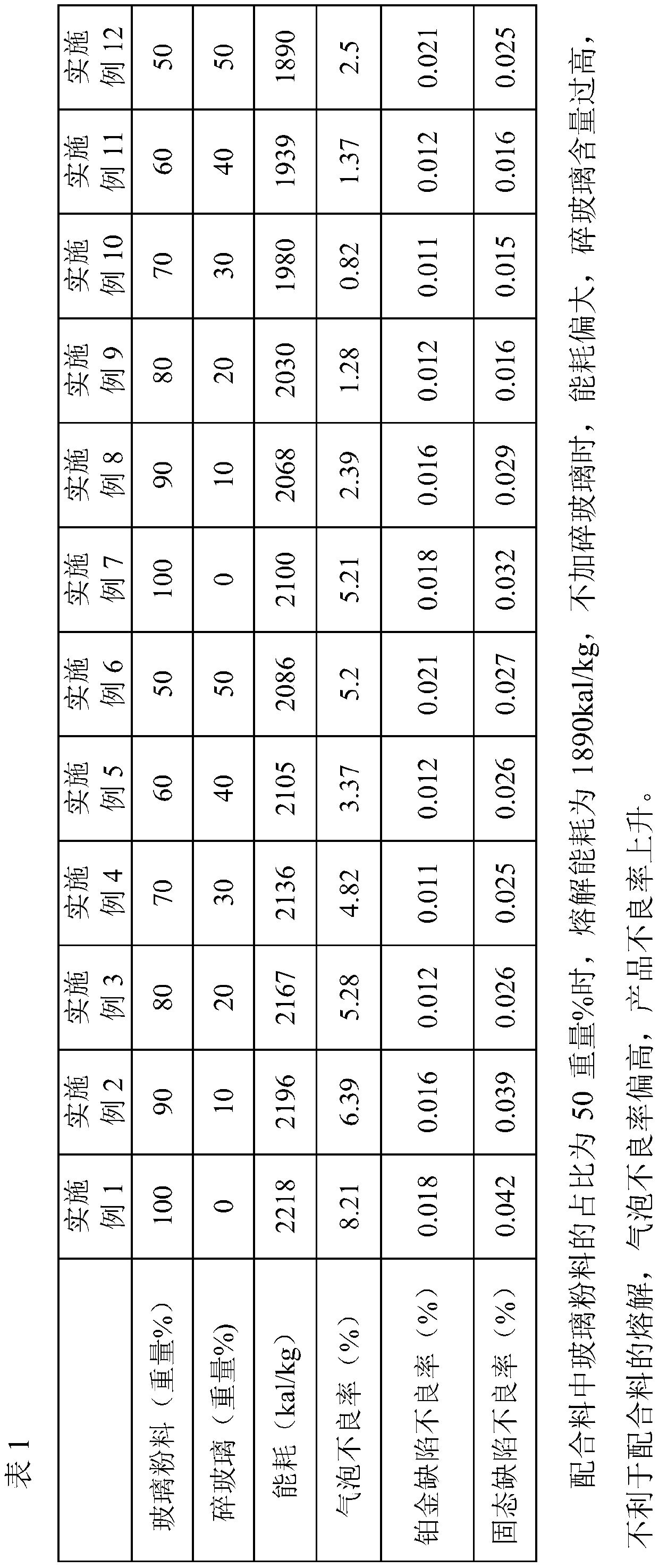

Embodiment 1-6

[0066] Based on the total molar weight of the glass composition, in terms of oxides, the glass composition is:

[0067] SiO 2 : 65mol%, Al 2 o 3 : 14.6mol%, B 2 o 3 : 7mol%, MgO: 2.8mol%, CaO: 3.1mol%, SrO: 2.1mol%, BaO: 4.7mol%, ZnO: 0.3mol%, impurities: 0.4mol%.

Embodiment 7-12

[0069] Based on the total molar weight of the glass composition, in terms of oxides, the glass composition is:

[0070] SiO 2 : 67.8mol%, Al 2 o 3 : 12.8mol%, B 2 o 3 : 0.8 mol%, MgO: 8.22 mol%, CaO: 5 mol%, SrO: 5.1 mol%, impurities: 0.28 mol%.

[0071]

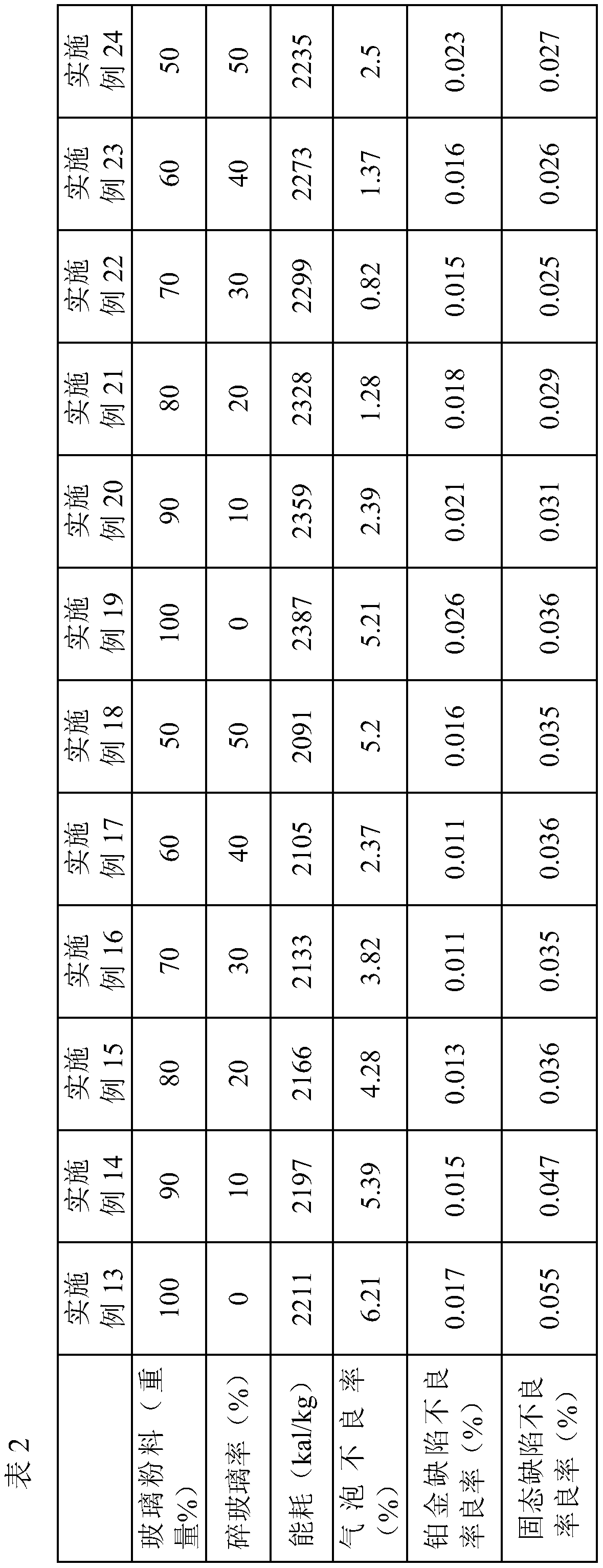

Embodiment 13-18

[0073] Based on the total molar weight of the glass composition, in terms of oxides, the glass composition is:

[0074] SiO 2 : 70mol%, Al 2 o 3 : 10.12mol%, B 2 o 3 : 4.11 mol%, MgO: 7.6 mol%, CaO: 3.2 mol%, SrO: 0.8 mol%, BaO: 4 mol%, ZnO: 0.1 mol%, impurities: 0.07 mol%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com