BN (Boron nitride)-modified SiO2 composite material and preparation method thereof

A composite material and modification technology, which is applied in the field of material processing, can solve the problems of brittle failure of composite materials, lack of reinforcement and toughening of quartz fibers, high preparation temperature, etc., and achieve good moisture absorption ability, short cycle and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

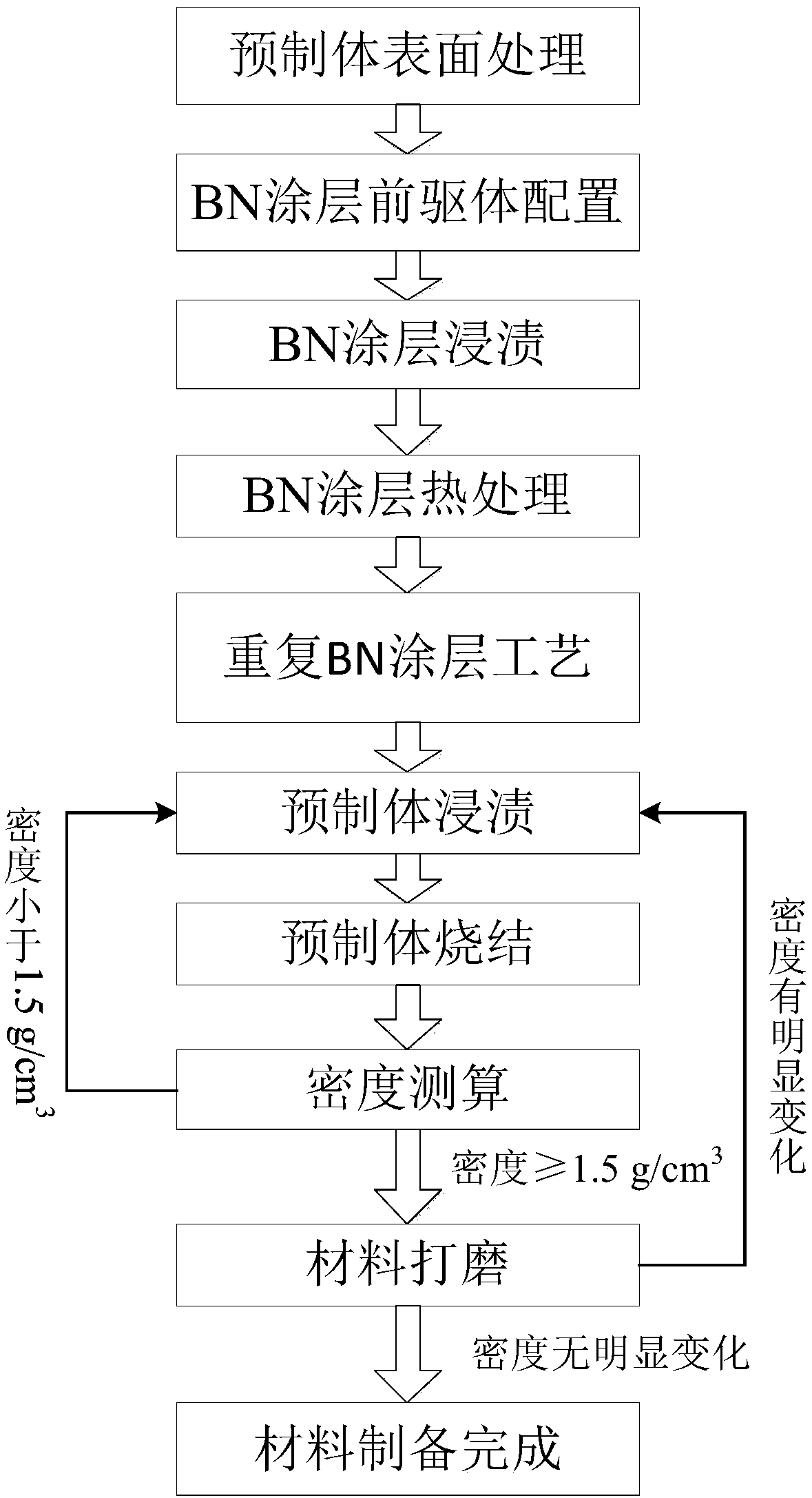

[0024] Example 1 A kind of SiO modified with BN coating for radome and antenna window is proposed 2f / SiO 2 composite materials such as figure 1 As shown, its preparation method comprises the following steps:

[0025] (1) First, the 2D SiO 2f The preform was soaked in absolute ethanol for 22h, then placed at room temperature for 74h, then placed in a muffle furnace, heated to 550°C at a heating rate of 450°C / h, kept for 3 hours, and then cooled to room temperature.

[0026] (2) Dissolve boric acid and urea with a mass ratio of 1:2.5 in a mixed solution of ethanol and water with a volume ratio of 2:1, and stir to dissolve completely until the solution is clear and transparent, and then adjust the pH of the solution to 7.0.

[0027] (3) SiO treated in step (1) 2f The preform is put into the impregnation tank, and the solution obtained in step (2) is injected, then vacuumized and maintained for 0.3h, and then the protective gas is introduced to 1.103×10 5 Pa and maintained ...

Embodiment 2

[0035] Example 2 A kind of SiO modified with BN coating for radome and antenna window is proposed 2f / SiO 2 The composite material, its preparation method comprises the steps:

[0036] (1) First, 2.5D SiO 2f The preform was soaked in absolute ethanol for 26h, then placed at room temperature for 70h, then placed in a muffle furnace, heated to 450°C at a heating rate of 550°C / h, kept for 5h, and then cooled to room temperature.

[0037] (2) Dissolve boric acid and urea with a mass ratio of 1:1.5 in a mixed solution of ethanol and water with a volume ratio of 4:1, and stir to dissolve completely until the solution is clear and transparent, and then adjust the pH of the solution to 5.0.

[0038] (3) SiO treated in step (1) 2f The preform is put into the impregnation tank, and the solution obtained in step (2) is injected, then vacuumized and maintained for 0.8h, and then the protective gas is introduced to 8.104×10 4 Pa and maintained pressure for 0.8h, then taken out and dri...

Embodiment 3

[0046] Example 3 A kind of SiO modified with BN coating for radome and antenna window is proposed 2f / SiO 2 The composite material, its preparation method comprises the steps:

[0047] (1) First, the 3D SiO 2f The preform was soaked in absolute ethanol for 24 hours, then placed at room temperature for 72 hours, then placed in a muffle furnace, heated to 500°C at a heating rate of 500°C / h, kept for 4 hours, and then cooled to room temperature.

[0048] (2) Dissolve boric acid and urea with a mass ratio of 1:2 in a mixed solution of ethanol and water with a volume ratio of 3:1, and stir to dissolve them completely until the solution is clear and transparent, and then adjust the pH of the solution to 6.0.

[0049] (3) SiO treated in step (1) 2f The preform is put into the impregnation tank, and the solution obtained in step (2) is injected, then vacuumized and maintained for 0.5h, and then the protective gas is introduced to 9.927×10 4 Pa and maintained pressure for 0.5h, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com