A kind of thermosetting resin composition and prepreg and laminated board prepared by using it

A resin composition, thermosetting technology, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of low glass transition temperature, poor adhesion, poor heat resistance, etc., and achieve cross-linking density. Large, small thermal shrinkage, the effect of improving peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

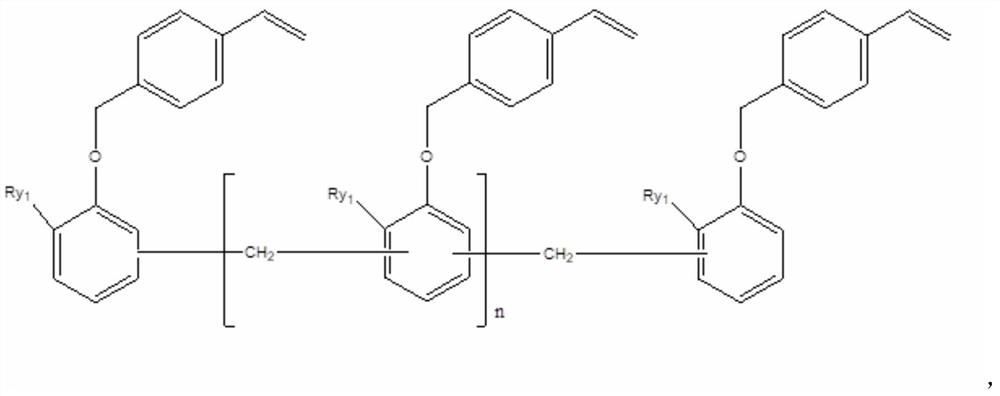

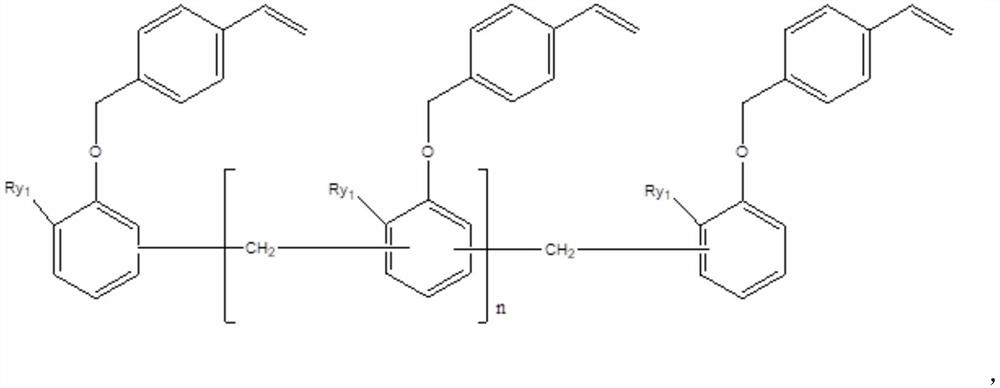

Image

Examples

Synthetic example 1

[0080] Put 1000g of tetrahydrofuran, 100g of dicyclohexylcarbodiimide, 58.8g of maleic anhydride, and 228g of bisphenol A into the three-necked reaction flask, fully dissolve them, put them in the three-necked reaction flask and mix them thoroughly, and then add a catalytic amount of 4-dimethylaminopyridine, reacted at room temperature for 5 hours, then separated and purified the product to obtain active ester resin A-1, and the hydroxyl functional group equivalent in the active ester (A-1) resin was calculated as 690 grams / equivalent based on the input ratio (58.8+228-18*0.6=276, 276 / 0.4=690), the ester group functional equivalent is 230 g / equivalent based on the input ratio, and the unsaturated double bond functional equivalent is 460 g / equivalent.

[0081] In a flask equipped with a thermometer, dropping funnel, condenser, shunt pipe, and stirrer, put 1000 g of methyl isobutyl ketone into the solvent, then take 276 g of resin A-1 and put it into the flask to fully dissolve. ...

Synthetic example 2

[0083] Put 1000g of tetrahydrofuran, 100g of dicyclohexylcarbodiimide, 58.8g of maleic anhydride, and 160g of 2,7 dihydroxynaphthalene into the three-neck reaction flask, fully dissolve them, mix them fully in the three-neck reaction flask, and then add A catalytic amount of 4-dimethylaminopyridine was reacted at room temperature for 5 hours, and then the product was separated and purified to obtain an active ester resin (A-2), and the hydroxyl functional group equivalent in the active ester (A-2) resin was calculated based on the input ratio It is 520 g / equivalent (58.8+160-18*0.6=208, 208 / 0.4=520), the ester group functional equivalent is 173 g / equivalent based on the input ratio, and the unsaturated double bond functional equivalent is 347 g / equivalent.

[0084] In a flask equipped with a thermometer, dropping funnel, condenser, shunt pipe, and stirrer, put 1000 g of solvent methyl isobutyl ketone, then take 208 g of resin A-2 into the flask, and fully dissolve it. Nitrogen...

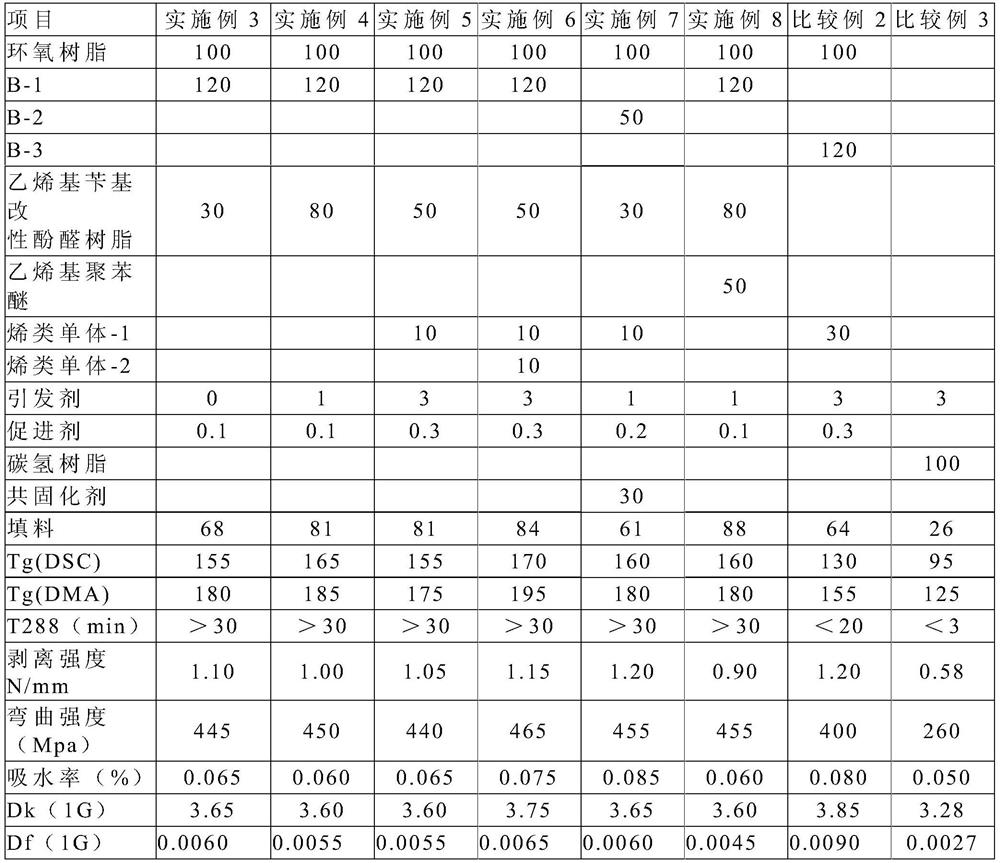

Embodiment 1~8 and comparative example 2~3

[0089] According to the formula shown in table 1, at first it is necessary to prepolymerize the unsaturated polyester active ester, ethylenic crosslinking agent and initiator in embodiment 5 into prepolymer according to the method of embodiment 1, and the unsaturated polyester in embodiment 6 Saturated polyester active ester, ethylenic crosslinking agent, and initiator are prepolymerized into a prepolymer according to the method in Example 2. Examples 3-4, Examples 7-8 and Comparative Examples 2 and 3 did not carry out pre-polymerization, but ordinary physical blending, which will not be specifically described here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com