A thermal shock-resistant boron nitride-strontium feldspar ceramic matrix composite material and its preparation method

A composite material and boron nitride technology are applied in the field of thermal shock boron nitride-strontium feldspar ceramic matrix composite materials and their preparation, which can solve the problems of limited application of strontium feldspar, poor machinability, low density and low thermal expansion coefficient, etc. , to achieve the effect of good mechanical and processability, high density, good dielectric and thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

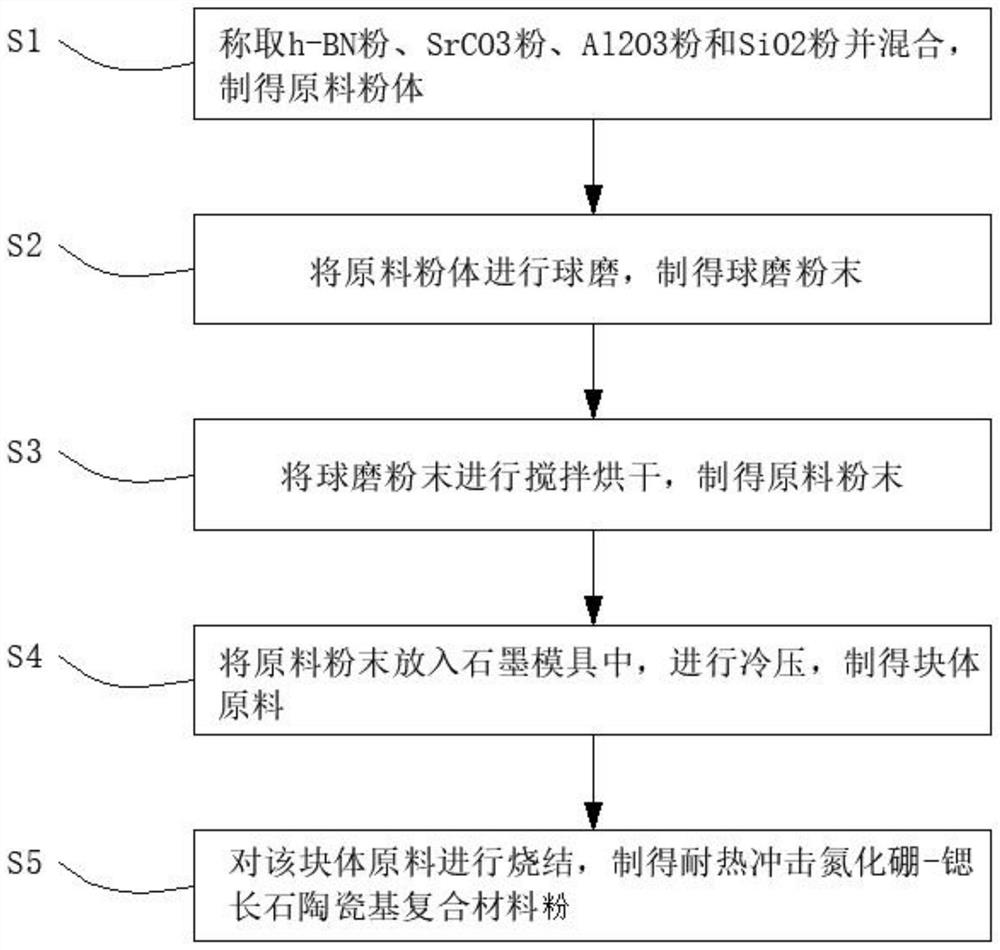

[0033] In order to solve the problem of poor machinability of strontium feldspar, the present invention provides a thermal shock-resistant boron nitride-strontium feldspar ceramic matrix composite material and a preparation method of the composite material, see figure 1 As shown, wherein the preparation method of thermal shock-resistant boron nitride-strontium feldspar ceramic matrix composite material comprises the following steps:

[0034] S1: Weigh h-BN powder, SrCO 3 Powder, Al 2 o 3 Powder and SiO 2 powder and mix to obtain raw material powder;

[0035] S2: ball milling the raw material powder to obtain ball milling powder;

[0036] S3: stirring and drying the ball mill powder to obtain raw material powder;

[0037] S4: Put the raw material powder into a graphite mold and perform cold pressing to obtain a bulk raw material;

[0038] S5: Sintering the bulk raw material to prepare a thermal shock resistant boron nitride-strontium feldspar ceramic matrix composite mate...

Embodiment 1

[0060] This embodiment provides a method for preparing a thermal shock-resistant boron nitride-strontium feldspar ceramic matrix composite material, the method comprising:

[0061] S1: Weigh 23g of h-BN powder with a particle size of 100 mesh and a purity of 99wt%, and SrCO with a particle size of 100 mesh and a purity of 99.5wt%. 3 Powder 14.83g, particle size is 100 mesh, purity is 99.5wt% Al 2 o 3 Powder 10.88g, particle size is 100 orders, the SiO that purity is 99.5wt% 2 Powder 13.09g, mix, make raw material powder;

[0062] S2: Put the raw material powder in a polytetrafluoroethylene ball mill tank, use alumina balls, add absolute ethanol to carry out wet ball milling for 1 hour, and obtain a ball mill powder;

[0063] S3: stirring and drying the ball mill powder at 60° C. for 24 hours to obtain raw material powder;

[0064] S4: Put the raw material powder into a graphite mold with a diameter of 50 mm and the inner wall is coated with boron nitride, and cold press at...

Embodiment 2

[0077] This embodiment provides a method for preparing a thermal shock-resistant boron nitride-strontium feldspar ceramic matrix composite material, the method comprising:

[0078] S1: Weigh 8.2g of h-BN powder with a particle size of 200 mesh and a purity of 99wt%, and SrCO with a particle size of 200 mesh and a purity of 99.5wt%. 3 Powder 7.34g, particle size is 200 orders, and purity is the Al of 99.5wt%. 2 o 3 Powder 10.88g, particle size is the SiO of 200 orders, purity is 99.5wt% 2 Powder 13.09g, mix, make raw material powder;

[0079] S2: Put the raw material powder in a polytetrafluoroethylene ball mill tank, use alumina balls, add absolute ethanol to carry out wet ball milling for 12 hours to obtain a ball mill powder;

[0080] S3: stirring and drying the ball mill powder at 60° C. for 36 hours to obtain raw material powder;

[0081] S4: Put the raw material powder into a graphite mold with a diameter of 50 mm and an inner wall coated with boron nitride, and cold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com