Cover plate of induction identification module, and preparation method and application thereof

A cover sheet and module technology, which is used in character and pattern recognition, instruments, computer parts, etc., can solve the problems of affecting the dielectric properties of the cover sheet, prone to warping edges, poor ceramic body density, etc. The effect of compactness, good surface flatness and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

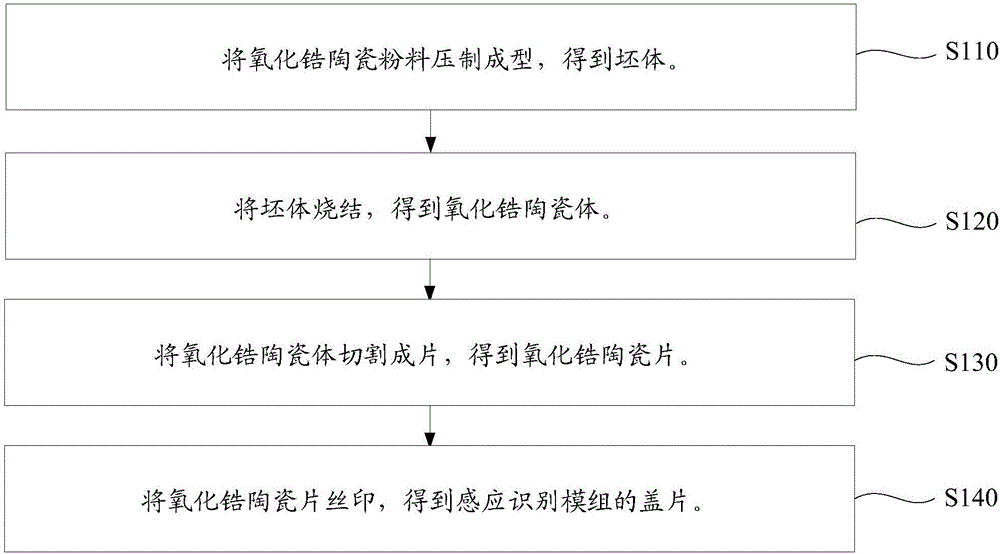

[0026] Such as figure 1 As shown, the preparation method of the cover sheet of the inductive identification module in an embodiment, wherein the inductive identification module can be, for example, a fingerprint identification module, etc., the preparation method of the cover sheet of the inductive identification module includes the following steps:

[0027] Step S110: Press and shape the zirconia ceramic powder to obtain a green body.

[0028] Among them, before the step of pressing the zirconia ceramic powder, the preparation step of the zirconia ceramic powder is also included: the zirconia powder is mixed with organic additives for granulation to obtain the zirconia ceramic powder, wherein the zirconia powder The median diameter of the body is 0.54 microns to 0.68 microns. Organic additives are generally binders, such as PVA (polyvinyl alcohol) and the like.

[0029] Since the particle size of the material directly affects the microstructure of the sintered ceramic body,...

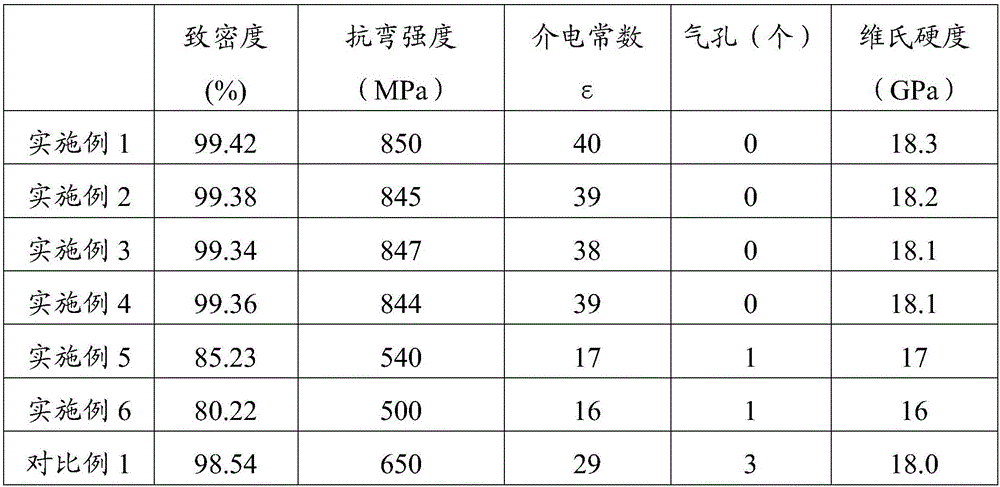

Embodiment 1

[0053] The preparation process of the cover sheet of the induction recognition module of this embodiment is as follows:

[0054] (1) Mix zirconia powder with a median diameter of 0.54 microns and polyvinyl alcohol at a mass ratio of 12:1, and spray granulate to obtain zirconia ceramic powders with a particle size of 80 microns to 150 microns. The zirconia ceramic powder is cold isostatically pressed to obtain a solid green body with a diameter of 70 mm and a length of 70 mm. The pressure during cold isostatic pressing is 160 MPa, and the pressing time is 1 minute.

[0055] (2) Sinter the green body obtained in step (1) under normal pressure, raise the temperature from room temperature to 750°C at a rate of 1°C / min, keep it warm for 1 hour, and then heat up to 750°C at a rate of 2°C / min 1200°C, keep it warm for 1 hour, then raise the temperature to 1400°C at a heating rate of 1°C / min, keep it warm for 1 hour, then raise the temperature to 1500°C at a heating rate of 1°C / min, ke...

Embodiment 2

[0061] The preparation process of the cover sheet of the induction recognition module of this embodiment is as follows:

[0062] (1) Mix zirconia powder with a median diameter of 0.68 microns and polyvinyl alcohol at a mass ratio of 12:1, and spray granulate to obtain zirconia ceramic powders with a particle size of 80 microns to 150 microns. The zirconia ceramic powder is cold isostatically pressed to obtain a solid green body with a diameter of 70 mm and a length of 70 mm. The pressure during cold isostatic pressing is 120 MPa, and the pressing time is 1 minute.

[0063] (2) Sinter the green body obtained in step (1) under normal pressure, raise the temperature from room temperature to 600°C at a heating rate of 2°C / min, keep it warm for 2 hours, and then heat up to 600°C at a heating rate of 3°C / min 1000°C, keep warm for 3 hours, then raise the temperature to 1300°C at a heating rate of 2°C / min, and keep warm for 2 hours, then raise the temperature to 1450°C at a heating ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com