Liquid crystal polymer composite material and preparation method thereof

A technology of liquid crystal polymers and composite materials, which is applied in the field of liquid crystal polymer composite materials and their preparation, can solve problems such as the difficulty of processing liquid crystal polymer materials into films, and achieve the effects of improved mechanical properties, easy film formation, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

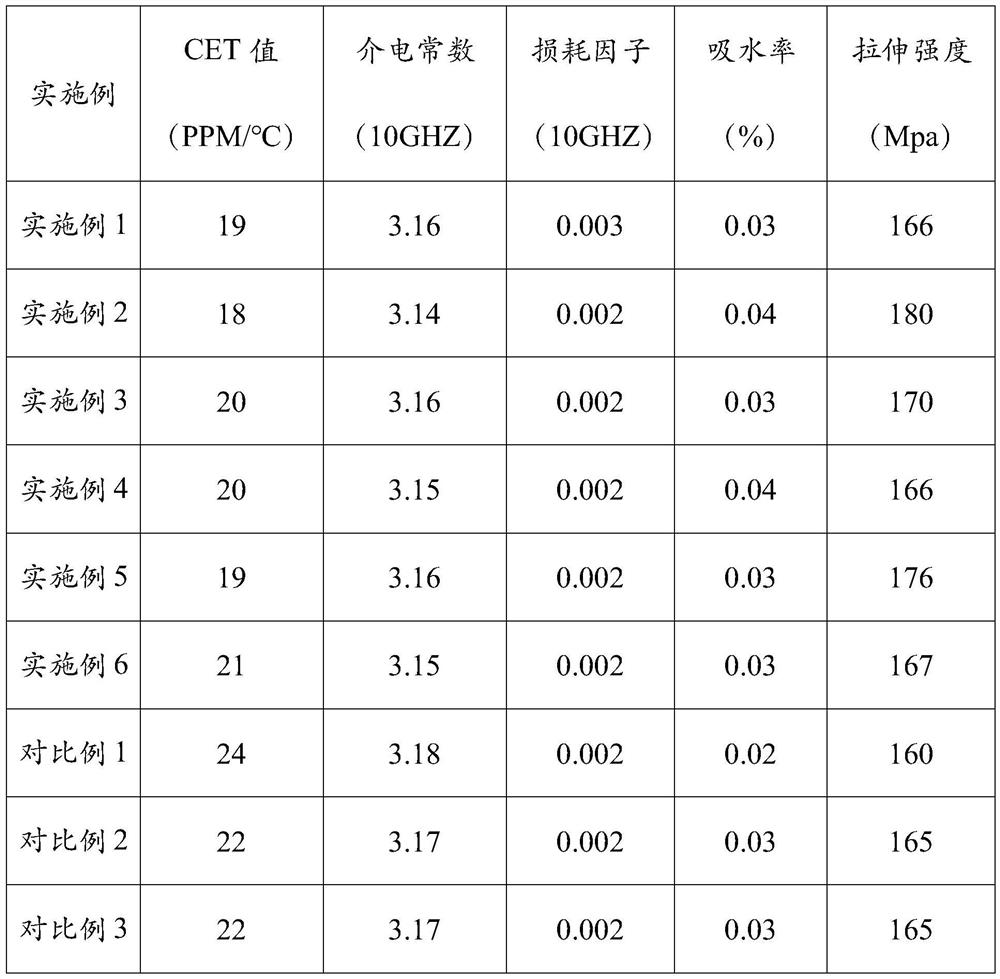

Examples

Embodiment 1

[0043] One embodiment of the present invention provides a method for preparing a liquid crystal polymer composite material, which includes the following steps:

[0044] 1) 90 parts of liquid crystal copolymer, 5 parts of polyester polymer and 5 parts of bisphenol A polycarbonate were fully dried in an oven at 100°C for 12 hours and then fully mixed to obtain a mixed base;

[0045] 2) Melt and mix the mixed base material in a co-rotating twin-screw extruder at 270° C. and 220 r / min, and then extrude and granulate to obtain a liquid crystal polymer composite material.

[0046] Among them, the melting point of the liquid crystal copolymer is 320°C, and the heat distortion temperature is 270°C.

[0047] The preparation method of the polyester polymer comprises: polycondensation and polymerization of bisphenol A and terephthalic acid to obtain the polyester polymer.

[0048] The preparation method of the bisphenol A polycarbonate comprises: post-condensation polymerization of bisp...

Embodiment 2

[0054] One embodiment of the present invention provides a method for preparing a liquid crystal polymer composite material, which includes the following steps:

[0055] 1) 80 parts of liquid crystal copolymer, 10 parts of polyester polymer and 10 parts of bisphenol A polycarbonate were fully dried in an oven at 100°C for 12 hours and then fully mixed to obtain a mixed base;

[0056] 2) Melt and mix the mixed base material in a co-rotating twin-screw extruder at 289° C. and 160 r / min, and then extrude and granulate to obtain a liquid crystal polymer composite material.

[0057] Among them, the melting point of the liquid crystal copolymer is 320°C, and the heat distortion temperature is 210°C.

[0058] The preparation method of the polyester polymer comprises: polycondensation and polymerization of bisphenol A and terephthalic acid to obtain the polyester polymer.

[0059] The preparation method of the bisphenol A polycarbonate comprises: post-condensation polymerization of bi...

Embodiment 3

[0065] One embodiment of the present invention provides a method for preparing a liquid crystal polymer composite material, which includes the following steps:

[0066] 1) 70 parts of liquid crystal copolymer, 15 parts of polyester polymer and 15 parts of bisphenol A polycarbonate were fully dried in an oven at 100°C for 12 hours and then fully mixed to obtain a mixed base;

[0067] 2) Melt and mix the mixed base material in a co-rotating twin-screw extruder at 280° C. and 200 r / min, and then extrude and granulate to obtain a liquid crystal polymer composite material.

[0068] Among them, the melting point of the liquid crystal copolymer is 260°C, and the heat distortion temperature is 210°C.

[0069] The preparation method of the polyester polymer comprises: polycondensation and polymerization of bisphenol A and terephthalic acid to obtain the polyester polymer.

[0070] The preparation method of the bisphenol A polycarbonate comprises: post-condensation polymerization of bisp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com