Thermosetting resin composition and prepregs and laminates produced by using the same

A technology of resin composition and prepreg, which is applied in the direction of synthetic resin layered products, lamination, lamination devices, etc., which can solve the problems of poor adhesion, damage to the dielectric properties of the system, and low heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

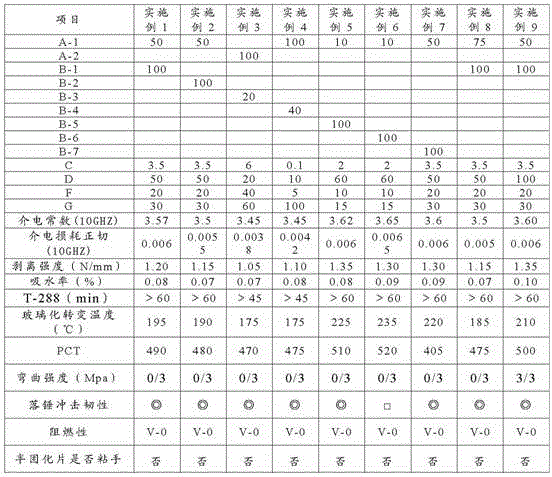

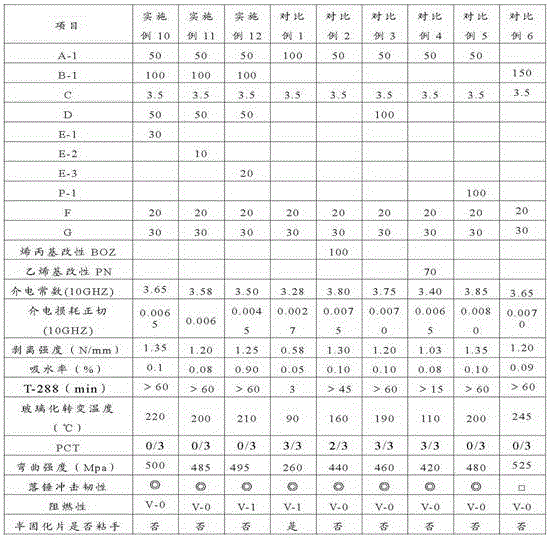

Examples

Synthetic example 1

[0069]Put N-(4-hydroxyphenyl)maleimide (190g, 1mol), phenol (94g, 1mol, M94) and oxalic acid (10g) into the flask equipped with thermometer, condenser and stirrer, mix and stir After uniformity, put it in a constant temperature water bath at 70°C; then, under stirring, add formaldehyde solution (150mL, the ratio of phenol / aldehyde to 1 / 0.8) dropwise into the flask for 0.5 hours; after adding formaldehyde, maintain 70°C The temperature and stirring conditions were reacted for 15 hours; then, the reaction product was dissolved and diluted with 400mL acetone, and then the reaction product was precipitated with 40% methanol aqueous solution; the above dissolution-precipitation operation was repeated 3 to 5 times, and it was filtered, separated, Drying yielded pure maleimide phenolic formaldehyde (P-1).

[0070] Take 100g of maleimide phenolic novolac (P-1) prepared by the above method and 500g of methyl isobutyl ketone solvent and put them in a flask to fully mix and dissolve, dep...

Synthetic example 2

[0073] With reference to the method of synthetic example 1, the maleimide ester (B-2) of following structure is obtained:

[0074] ; Among them, Ar is , R is phenyl;

[0075] Wherein, n is 1~10, and the ratio of x to y is 0.5:1.

Synthetic example 3

[0077] With reference to the method for synthetic example 1, the maleimide ester (B-3) of following structure is obtained:

[0078] ; Among them, Ar is: , R is maleimidophenyl;

[0079] Wherein, n is 1~10, and the ratio of x to y is 0.1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com