Low-temperature co-fired ceramic material emitting white light and preparation method thereof

A technology for low-temperature co-fired ceramics and ceramic materials, which is applied in the field of white light-emitting low-temperature co-fired ceramic materials and their preparation, and achieves the effects of simple and advanced preparation process, good uniformity and high luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

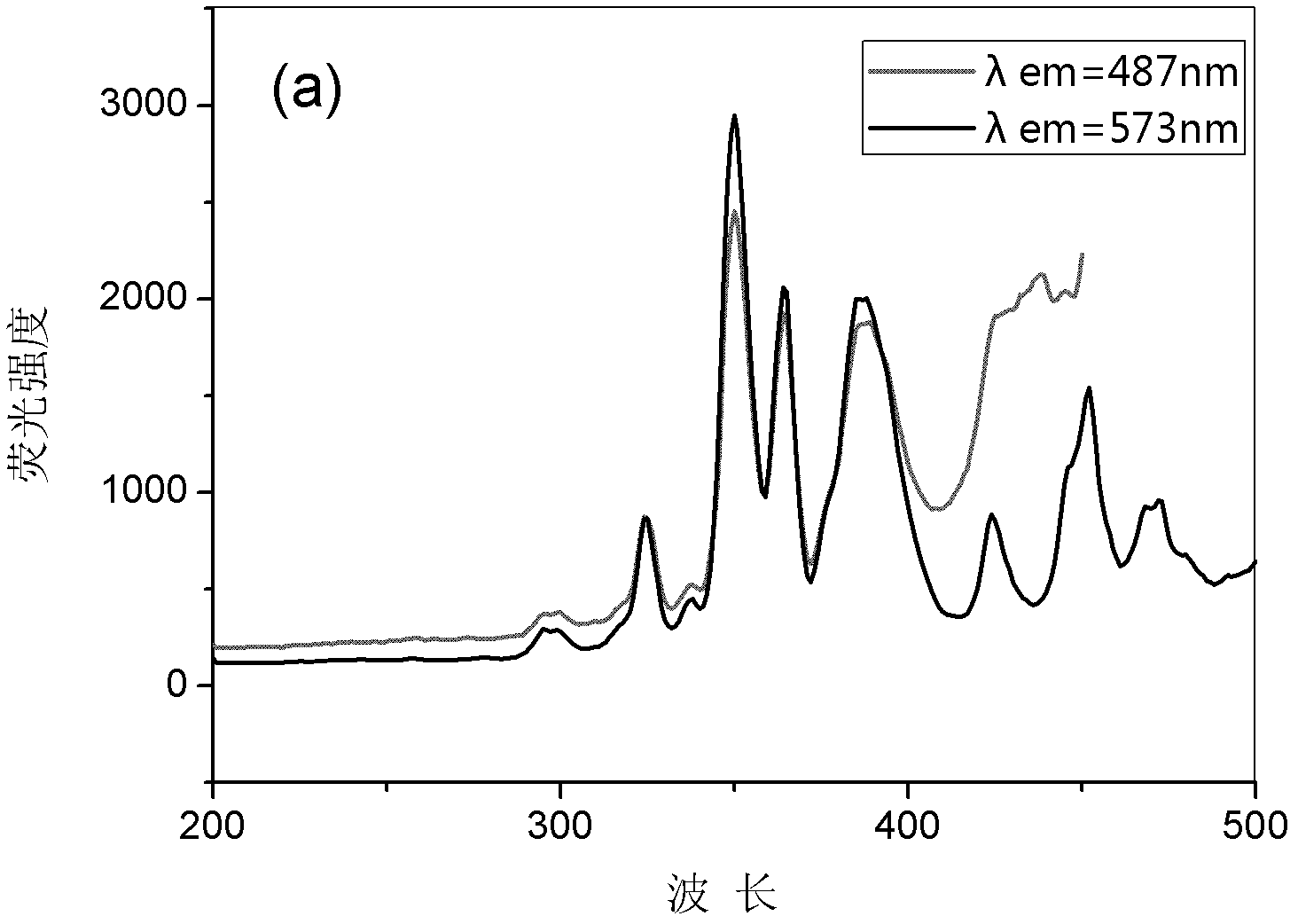

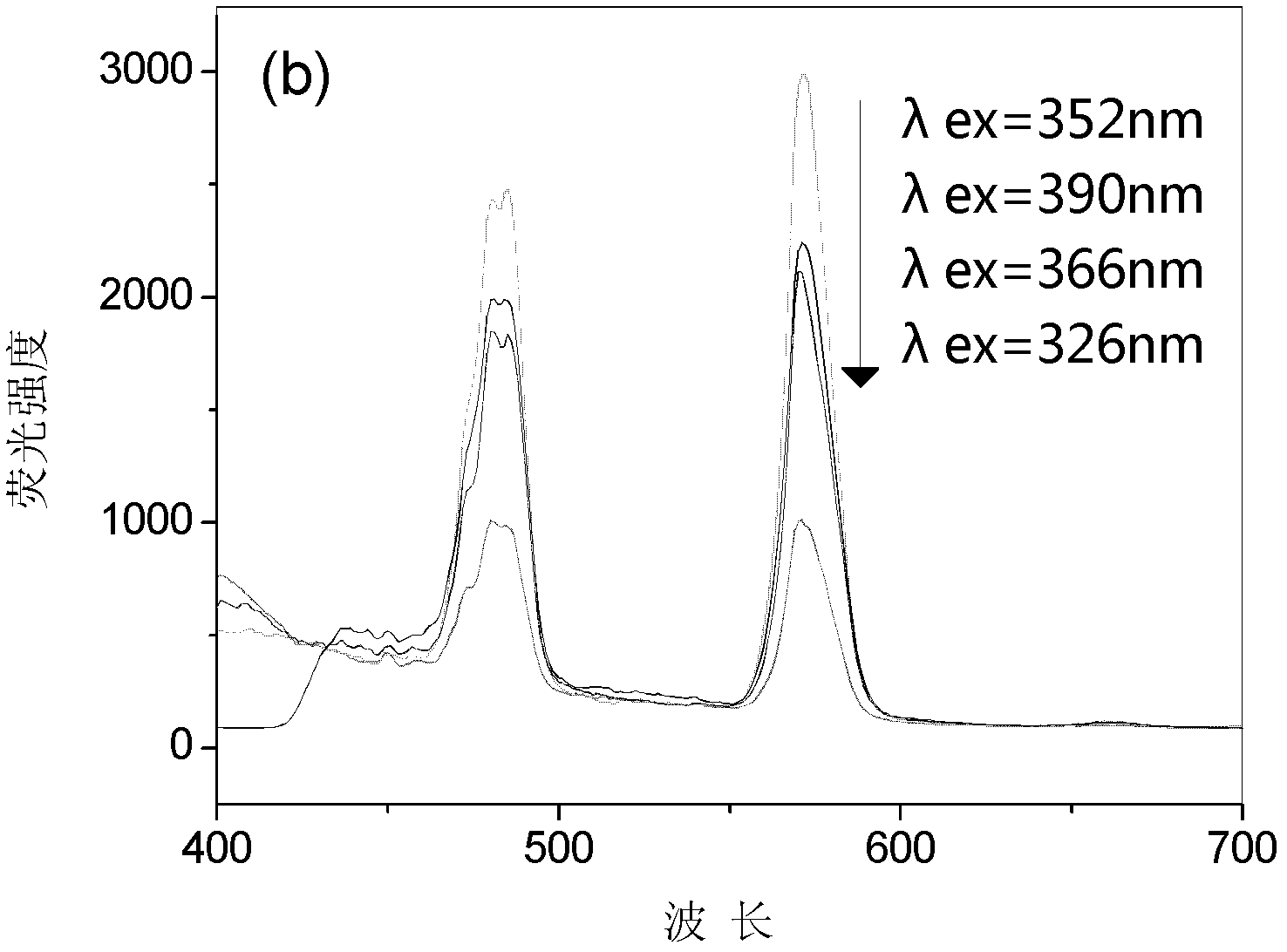

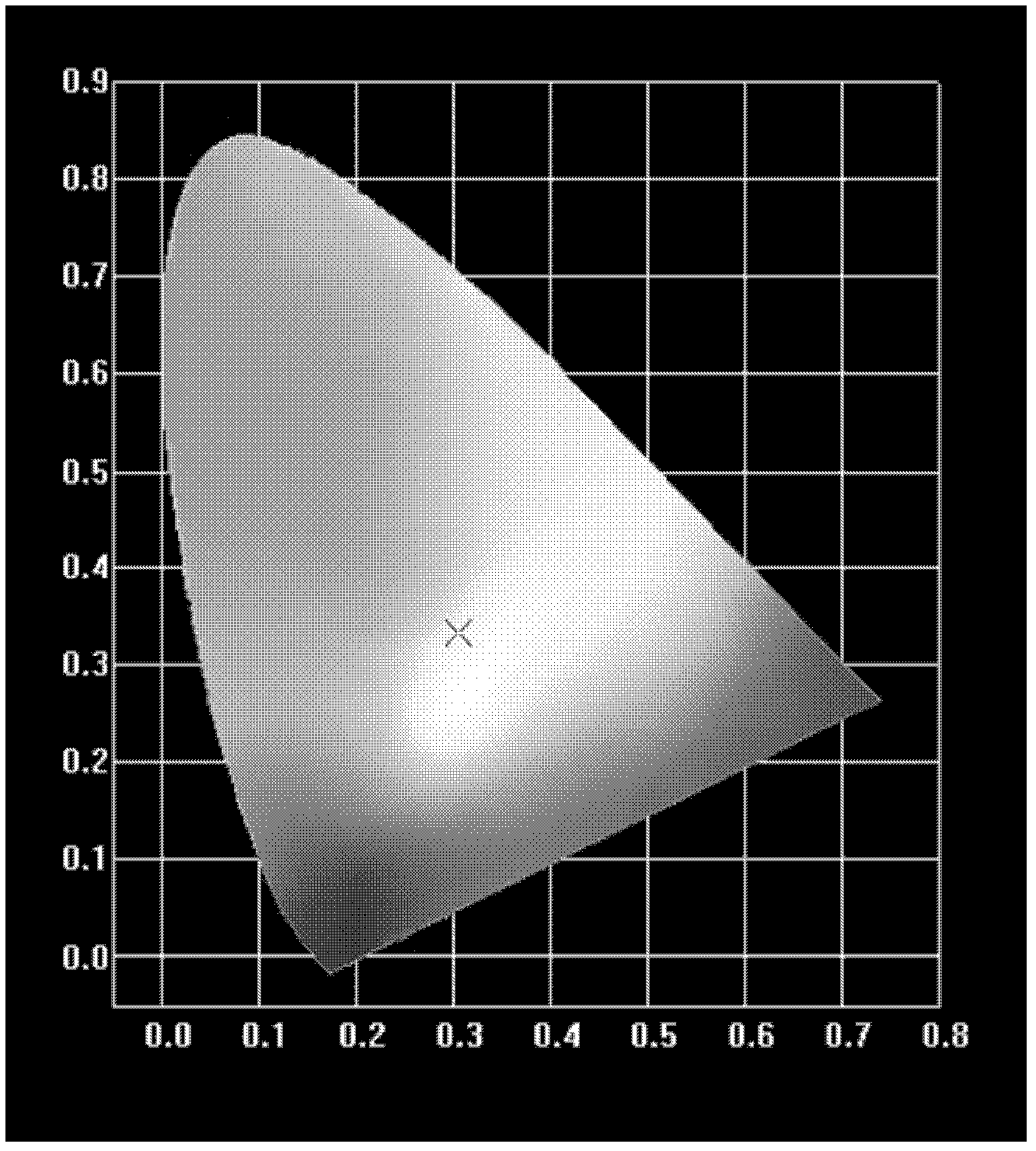

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 will account for the CaCO of mol percent 11% 3 , 9% by mole of Dy 3+ The corresponding amount of Dy 2 o 3 Soluble in HNO 3 make nitrate solution 3 Then add 25% B in mole percent 2 o 3 The corresponding amount of H 3 BO 3 The solution was mixed to prepare an inorganic solution, accounting for 55% Si(OC 2 h 5 ) 4 dissolved in anhydrous C 2 h 5 Prepare an organic solution in OH. Slowly pour the inorganic solution into the organic solution, wherein the volume ratio of the inorganic solution to the organic solution is 2:1. The mixed solution was stirred in a water bath at 80° C. for 1 hour to obtain a gel. The gel was heated in an oven at 80° C. for 8 hours to obtain a dry gel, and then placed in a high-temperature furnace for pre-calcination at 550° C. for 3 hours. Put the gel powder obtained after pre-burning into a ball mill jar, add absolute ethanol, ball mill for 4 hours and then dry. 10wt%-PVA solution was added to the obtained powder, and ...

Embodiment 2

[0030] Will be 20% by mole %CaCO 3 , Dy at 1% by mole 3+ The corresponding amount of Dy 2 o 3 Soluble in HNO 3 Prepare nitrate solution, and account for mole percentage 29%B 2 o 3 The corresponding amount of H 3 BO 3 The solution is mixed to prepare an inorganic solution, accounting for 50% Si(OC 2 h 5 ) 4 Soluble in anhydrous C 2 h 5 Prepare an organic solution in OH.

[0031] The inorganic solution was slowly poured into the organic solution, wherein the volume ratio of the inorganic solution to the organic solution was 2:1, and the mixed solution was stirred in a water bath at 80° C. for 2 hours to obtain a gel.

[0032] The gel was heated in an oven at 100°C for 6 hours to obtain a dry gel, and then placed in a high-temperature furnace for pre-calcination at 600°C for 2 hours.

[0033] The gel powder obtained after the pre-burning is completed is put into a ball mill jar, and absolute ethanol is added, ball milled for 2 hours and then dried.

[...

Embodiment 3

[0037]Will account for 15% by mole of CaCO 3 3% by mole Dy(NO 3 ) 3 Soluble in HNO 3 The prepared nitrate solution and accounted for 22% by mole of B 2 o 3 The corresponding amount of H 3 BO 3 The solution is mixed to prepare an inorganic solution, accounting for 60% Si(OC 2 h 5 ) 4 dissolved in anhydrous C 2 h 5 Prepare an organic solution in OH.

[0038] The inorganic solution was slowly poured into the organic solution, wherein the volume ratio of the inorganic solution to the organic solution was 2:1, and the mixed solution was stirred in a water bath at 100° C. for 1.5 hours to obtain a gel.

[0039] The gel was heated in an oven at 100° C. for 3 hours to obtain a dry gel, and then placed in a high-temperature furnace for pre-calcination at 500° C. for 4 hours.

[0040] The gel powder obtained after the pre-burning is completed is put into a ball mill jar, and absolute ethanol is added, ball milled for 6 hours and then dried.

[0041] 10wt%-PV...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com