A kind of thermosetting resin composition and prepreg and laminate made by using the same

A technology of resin composition and prepreg, applied in synthetic resin layered products, lamination, lamination devices, etc., can solve the problems of poor adhesion, low glass transition temperature, insufficient rigidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

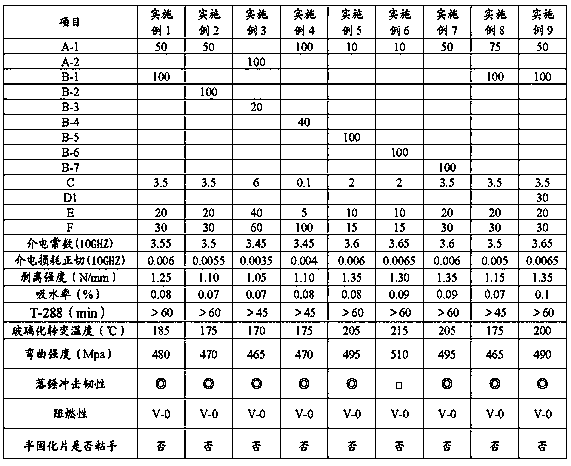

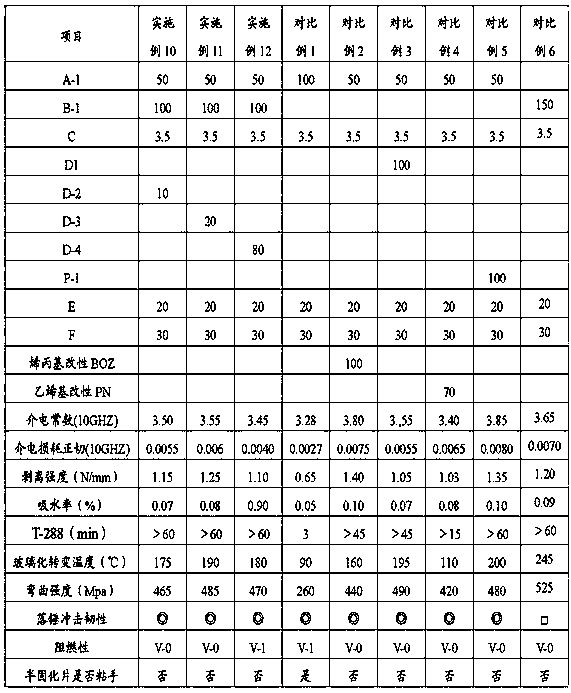

Examples

Synthetic example 1

[0057] Put N-(4-hydroxyphenyl)maleimide (190g, 1mol), phenol (94g, 1mol, M94) and oxalic acid (10g) into the flask equipped with thermometer, condenser and stirrer, mix and stir After uniformity, place in a constant temperature water bath at 70°C; then, under stirring, add formaldehyde solution (150mL, phenol / aldehyde ratio 1 / 0.8) to the flask over 0.5 hours; after adding formaldehyde, maintain 70°C The reaction product was dissolved and diluted with 400 mL of acetone at the temperature and stirring conditions for 15 hours; then, the reaction product was precipitated with a 40% methanol aqueous solution; the above dissolution-precipitation operation was repeated 3 to 5 times, and it was filtered, separated, Dry to obtain pure maleimide phenolic (P-1).

[0058] Take 100g of maleimide phenolic (P-1) prepared by the above method and 500g of methyl isobutyl ketone solvent and put them in a flask to fully mix and dissolve. The reaction system is depressurized and nitrogen is introduce...

Synthetic example 2

[0061] Referring to the method of actual synthesis example 1, the maleimide ester (B-2) with the following structure was prepared:

[0062] ; Among them, Ar is , R is phenyl;

[0063] Among them, n is 1-10, and the ratio of x to y is 0.5:1.

Synthetic example 3

[0065] Referring to the method of Synthesis Example 1, the maleimide ester (B-3) of the following structure was prepared:

[0066] ; Among them, Ar is: , R is maleimidophenyl;

[0067] Among them, n is 1-10, and the ratio of x to y is 0.1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com