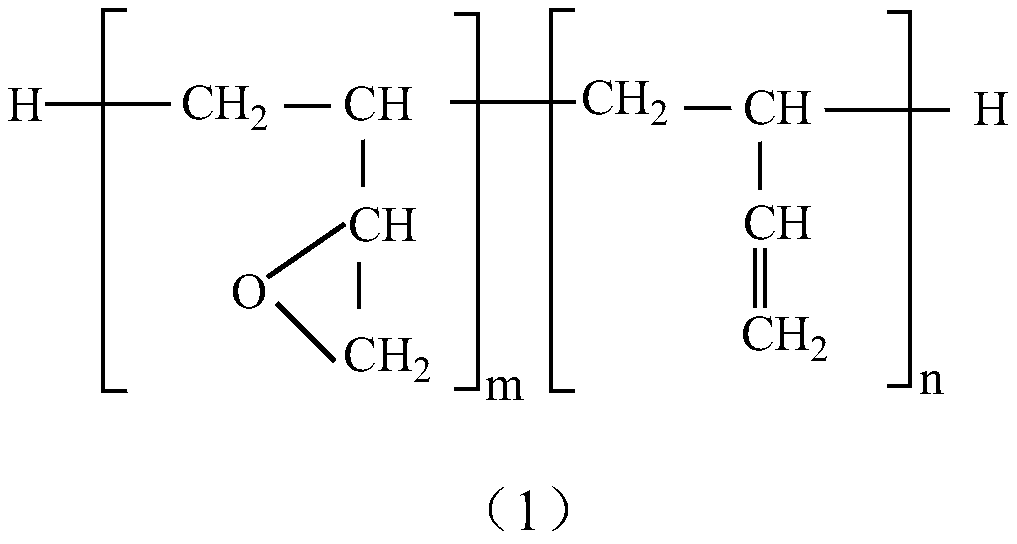

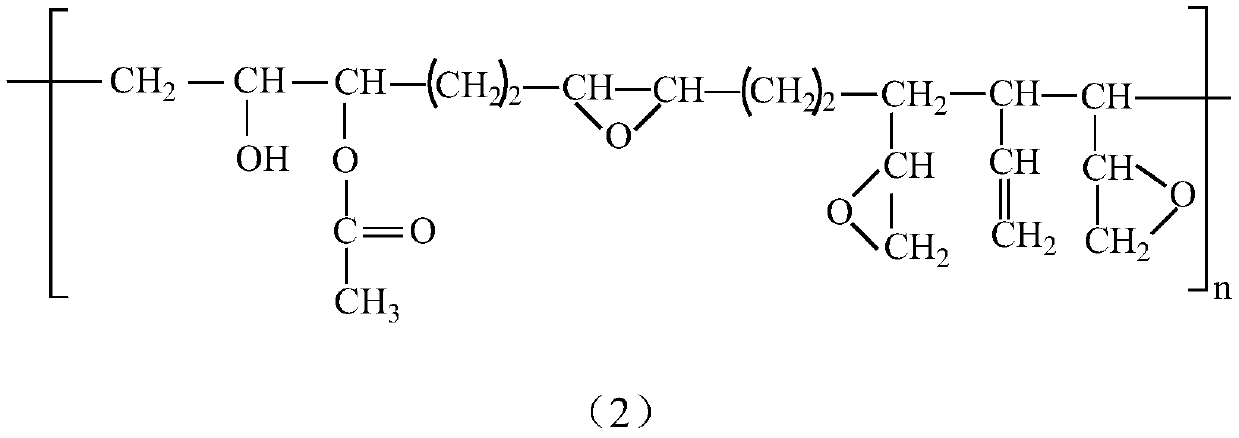

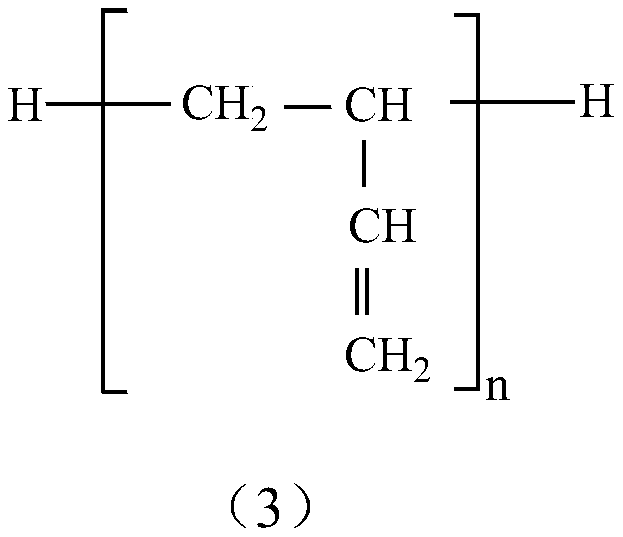

A modified polybutadiene prepolymer and its preparation method and application

A technology for polybutadiene and epoxidized polybutadiene is applied in the field of modified polybutadiene prepolymer and its preparation, which can solve the problem of poor compatibility and insufficient dielectric properties of polybutadiene. Reflection, low bromine-carbon bond energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Prepare JP100:BMI-1:CE-1:BP=100:40:30:1.5 prepolymer solid 100g (liquid 181.81g) according to the method in the synthesis example, add 10g phosphazene compound (SPB-100, Japan Otsuka Chemical), 8g styrene-butadiene copolymer (D1117, Kraton Polymers), 25DBPH 2g, 80g spherical silica (average particle size 0.7μm, SFP-30M, DENKA) and an appropriate amount of toluene solvent , Stir and mix evenly to obtain a glue solution with a solid content of 65%.

[0059] The glue is dipped and coated on E glass fiber cloth (2116, unit weight is 104g / m 2 ) and baked in an oven at 160°C for 5 minutes to obtain a prepreg with a resin content of 50%.

[0060] The prepared prepreg with a resin content of 50% was placed with a metal copper foil on the upper and lower sides, and pressed in a vacuum hot press to obtain a copper clad laminate. The specific pressing process is pressing at a pressure of 1.5Mpa and a temperature of 220° C. for 2 hours.

[0061] The properties of the obtained co...

Embodiment 2

[0064] Prepare JP100:BMI-2:CE-2:BP=100:50:40:1.5 prepolymer solid 100g (liquid 181.81g) according to the method in the synthesis example, add 9g phosphazene compound (SPB-100, Japan Otsuka Chemical), 8g styrene-butadiene copolymer (D1117, Kraton Polymers), 25DBPH2g, 80g spherical silica (average particle size 0.7μm, SFP-30M, DENKA) and an appropriate amount of toluene solvent, Stir and mix evenly to obtain a glue solution with a solid content of 65%.

[0065] The preparation methods of the prepreg and the copper-clad laminate are the same as in the first embodiment.

[0066] The properties of the obtained copper-clad laminates are shown in Table 2.

[0067] The preparation method of the interlayer insulating film is the same as the first embodiment.

Embodiment 3

[0069] Prepare JP100:BMI-3:CE-2:BP=100:45:45:1.5 prepolymer solid 100g (liquid 181.81g) according to the method in the synthesis example, add 11g phosphazene compound (SPB-100, Japan Otsuka Chemical), 8g styrene-butadiene copolymer (D1117, Kraton Polymers), 25DBPH2g, 80g spherical silica (average particle size 0.7μm, SFP-30M, DENKA) and an appropriate amount of toluene solvent, Stir and mix evenly to obtain a glue solution with a solid content of 65%.

[0070] The preparation methods of the prepreg and the copper-clad laminate are the same as in the first embodiment.

[0071] The properties of the obtained copper-clad laminates are shown in Table 2.

[0072] The preparation method of the interlayer insulating film is the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com