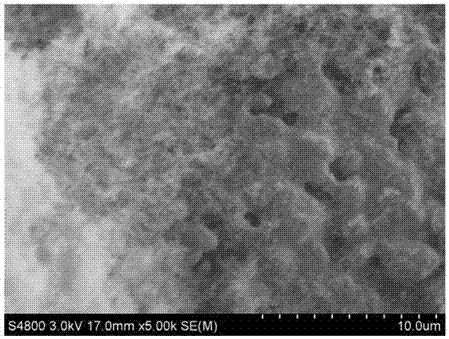

Silicon dioxide aerogel based composite shielding layer and preparation method thereof

A composite shielding layer and silicon dioxide technology, applied in electrical components, ceramic products, and other household appliances, can solve the problems of low strength, high brittleness, and easy cracking of pure silica airgel, and achieve good support performance , Density increase, and the effect of improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Put 10 ppi of polyurethane foam in a NaOH solution with a mass concentration of 10%, and treat it in a water bath at 60° C. in a constant temperature water bath for 3 hours. After taking it out, rub it repeatedly to remove the film between the tendons of the organic foam, and repeatedly rinse and dry it with deionized water to obtain a pretreated organic foam; then immerse the pretreated organic foam in a 5% polyvinyl alcohol solution for 12 hours Take out and dry afterward, obtain organic polyurethane foam;

[0034] 2) 50g of SiO with an average particle size of 500nm 2 Mix the micropowder with 75mL of deionized water, add 1.5g of boric acid, then add 1g of carboxymethyl fiber and 5mL of ammonium polyacrylate, stir and dissolve at a high speed and mix evenly to obtain a silica ceramic slurry;

[0035] 3) Immerse the 10ppi organic polyurethane foam treated in step 1) completely in step 2) in the stirred silica ceramic slurry, within 4 Treat under a vacuum of Pa for ...

Embodiment 2

[0041] 1) Put 20ppi polyurethane foam in a NaOH solution with a mass concentration of 15%, and treat it in a water bath at 60° C. for 1 hour. After taking it out, fully rub the film between the tendons of the organic foam, rinse it with deionized water several times, and dry it to obtain the pretreated organic foam; then immerse the pretreated organic foam into a polyvinyl alcohol solution with a mass fraction of 5%, Take out and dry after 15h, obtain organic polyurethane foam;

[0042] 2) 100g of SiO with an average particle size of 200nm 2 Mix the micropowder with 100mL of deionized water, add 3.6g of boric acid, then add 1g of carboxymethyl fiber and 10mL of ammonium polyacrylate, stir at high speed to dissolve and mix evenly to obtain a silica ceramic slurry;

[0043] 3) fully immerse the 20ppi organic polyurethane foam treated in step 1) into the silicon dioxide ceramic slurry stirred in step 2), and within 4 Treat under vacuum of Pa for 20 minutes to remove air bubbles ...

Embodiment 3

[0049] 1) Put 10 ppi of polyurethane foam in a NaOH solution with a mass concentration of 20%, and treat it in a water bath at 40° C. for 2 hours. After taking it out, rub it repeatedly to remove the film between the tendons of the organic foam, and repeatedly rinse and dry it with deionized water to obtain the pretreated organic foam; then immerse the pretreated organic foam in a polyvinyl alcohol solution with a mass fraction of 5% for 20 hours. Take out and dry to obtain organic polyurethane foam;

[0050] 2) 50g of SiO with an average particle size of 500nm 2 Mix the micropowder with 100mL of deionized water, add 2g of boric anhydride, then add 2g of carboxymethyl fiber and 5mL of ammonium polyacrylate, stir at high speed to dissolve and mix evenly to obtain a silica ceramic slurry;

[0051] 3) Immerse the 10ppi organic polyurethane foam treated in step 1) completely in step 2) in the stirred silica ceramic slurry, within 4 Treat under vacuum of Pa for 20 minutes to remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com