Reinforced halogen-free flame-retardant polyphenyl ether composition and preparation method and application thereof

A technology for polyphenylene ether and composition, which is applied in the field of reinforced halogen-free flame retardant polyphenylene ether composition and its preparation, can solve the problems of increased cost of fans, decreased mechanical properties of materials, large amount of addition required, etc., and achieves good dimensional stability. properties, excellent mechanical properties, and excellent oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

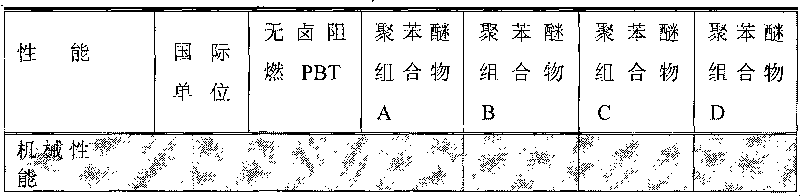

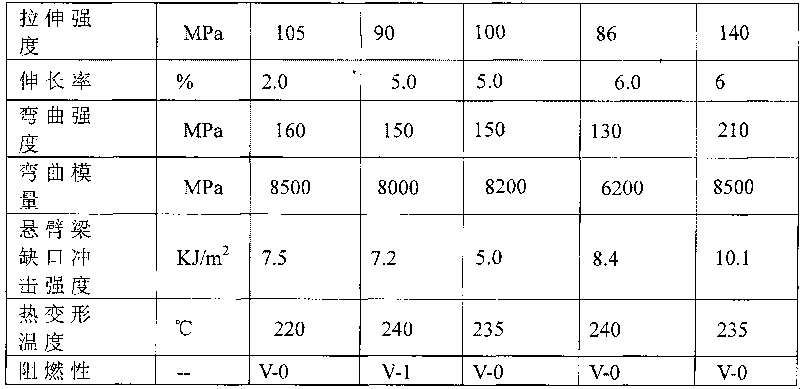

Embodiment 1

[0044] First, treat 300 parts of mica with 5 parts of γ-aminopropyltriethoxysilane for later use; weigh 200 parts of PPE, 50 parts of SEBS, 10 parts of maleic anhydride, 5 parts of antioxidant 1010, and 10 parts of silicone oil Premix with 200 parts of melamine phosphate (MPP), then add nylon-6, 6400 parts, and finally add 300 parts of treated mica through side feeding, melt and granulate at 260-280 ° C to obtain a polyphenylene ether combination Object A.

Embodiment 2

[0046] First, 300 parts of mica are treated with 5 parts of γ-aminopropyltriethoxysilane for later use; 600 parts of PPE, 50 parts of SEBS, 15 parts of fumaric acid, 10105 parts of antioxidant, 10 parts of silicone oil and Premix 150 parts of phosphinate, then add nylon-6, 6200 parts, and finally add 300 parts of treated mica through side feeding, melt and granulate at 260-280°C to obtain polyphenylene ether composition B.

Embodiment 3

[0048] First use 5 parts of γ-aminopropyltriethoxysilane to process 300 parts of talcum powder for later use; take by weight 400 parts of PPE, 50 parts of SEBS, 10 parts of citric acid, 5 parts of antioxidant 1010, stearic acid Premix 10 parts of zinc, 100 parts of phosphinate and 50 parts of melamine phosphate, then add 200 parts of nylon-6, and finally add 300 parts of treated talcum powder through side feeding, and melt and granulate at 260-280 °C , to obtain polyphenylene ether composition C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com