Low dielectric material

A low-dielectric material, polyphenylene ether technology, applied in the field of low-dielectric materials, can solve the problems of difficult forming, falling off, difficult processing, etc., and achieve the effects of high Tg, low water absorption, and low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The influence of embodiment 1PPE ratio difference

[0058]

[0059] Comparing the proportion relationship between Tg, Dk, Df and PPE, if the amount of PPE is too high or too low, Tg will be too low. At the same time, the amount of PPE will also affect Dk and Df. When the amount of PPE is high, both Dk and Df will be high. When the amount of PPE is low, both Dk and Df are low. In the best situation, both Dk and Df are low. In addition, adding PPE will increase the coefficient of thermal expansion, so the way of adding BMI is to reduce the coefficient of thermal expansion. The PPE (polyphenylene ether) model SA9000 in the table was purchased from Sabic Company. The chemical name is poly 2,6-dimethyl 1,4-phenylene ether, referred to as PPO (Polyphenylene Oxide) or PPE (Polypheylene ether), also known as polyphenylene oxide or polyphenylene ether.

Embodiment 2B

[0060] The influence of embodiment 2BMI resin structure and ratio difference

[0061]

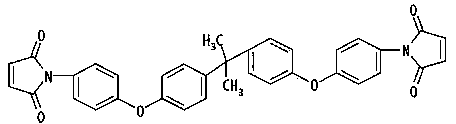

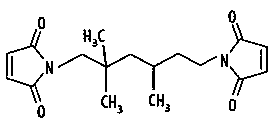

[0062] Comparing the relationship between thermal expansion coefficient and BMI (bismaleimide), the higher the ratio of BMI, the lower the thermal expansion coefficient. The comparison of BMI in this example can be divided into three parts, A1-A5 are the same type of BMI resin with different proportions, A6-A8 are the same proportion but different types of BMI, A9-A15 is the comparison of mixing multiple BMIs. The BMI models 2300, 4000, 5100, and TMH in the table are purchased from Daiwakaseilndustry CO., LTD. The chemical names are as follows.

[0063] BMI-2300

[0064] From A1 to A5, different proportions of the same type of BMI can effectively reduce the thermal expansion coefficient, but also have the effect of improving the water absorption rate. From A6-A8, different BMI can effectively reduce the thermal expansion coefficient, but it will also affect the water absorptio...

Embodiment 3

[0065] Embodiment 3 The impact of polymer additive structure and ratio difference

[0066]

[0067]

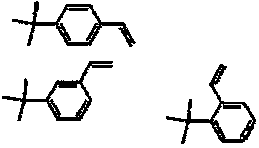

[0068] Comparing the relationship between water absorption and the use ratio of polymer additives (polymeradditves), using polybutadiene (Polybutadiene) and styrene-maleic anhydride copolymer (SMA), when using the same polybutadiene, The higher the ratio, the lower the water absorption, but the coefficient of thermal expansion will also increase. When using different kinds of polybutadiene and using it with SMA, it can be seen that SMA is more effective in reducing water absorption and can also reduce the coefficient of thermal expansion, but the performance in the Df part is poor, and the use of polybutadiene can make up for it Insufficiency of SMA in the Df part. The butadiene types Ricon100, Ricon130MA8, Ricon150 and Ricon257 in the table are purchased from Sartomer, and the chemical names are as follows.

[0069] Ricon100

[0070] The SMA listed in the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com