Mechanical pile forming method for high-bearing multi-stage club-footed pile

A technology of high bearing capacity and expanded bottom piles, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of difficult quality assurance, difficult quality control, bearing capacity attenuation, etc., to achieve a high degree of safety and reliability, improve strength The utilization rate and the effect of small diameter of the pile body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

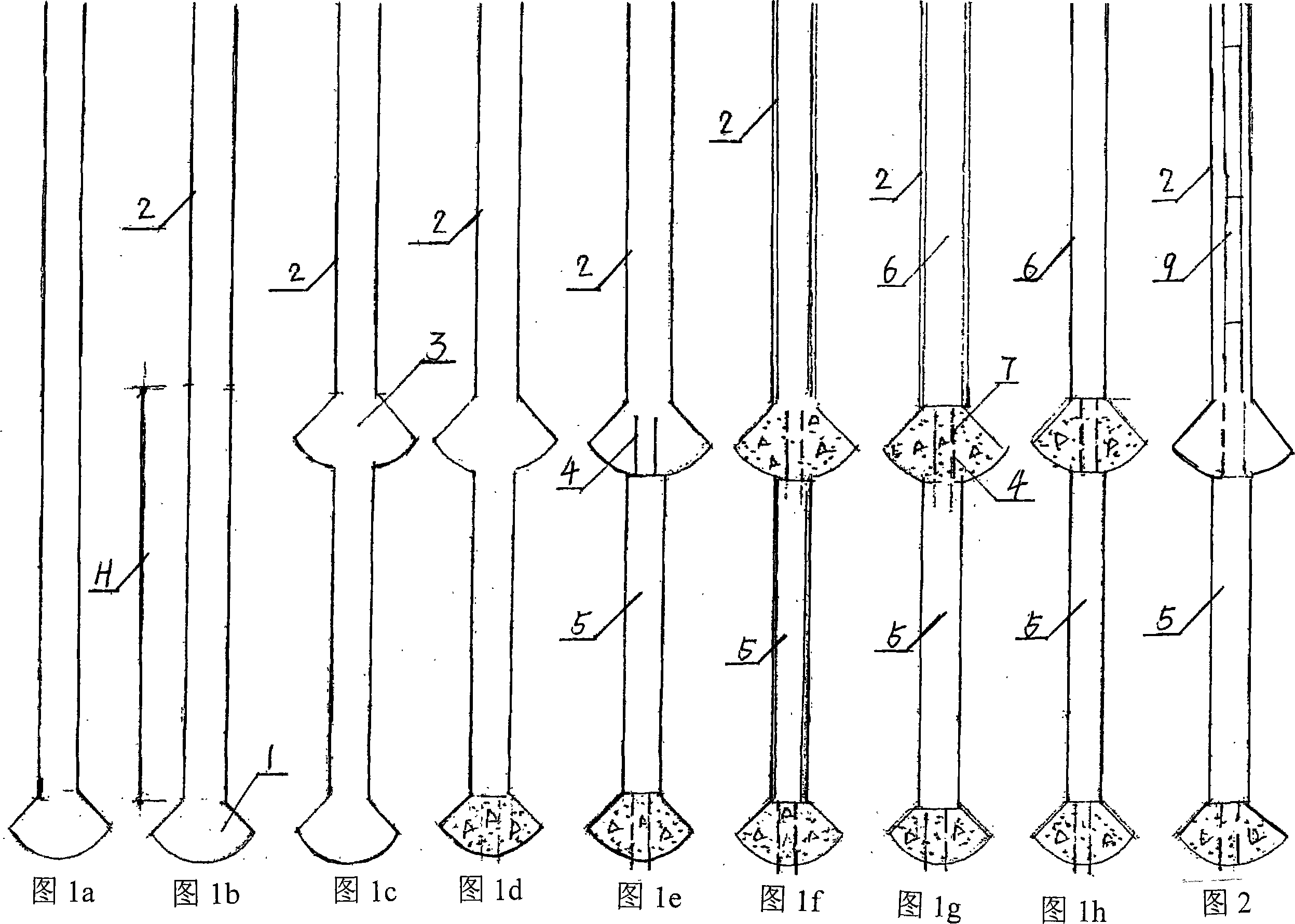

[0020] Shown in Figure 1a-1h is the schematic diagram of the construction status of each process of the pile forming method of the present invention, including the following process steps: a, sinking the immersed pipe 2 with the metal pile head into the hard soil layer to the design elevation; b, Take out the metal pile head; c, process the lower base space 1 with mechanical bottom expansion equipment or one of the positive and negative circulation methods, and take clean broken soil; d, pull up the sinking tube 2 to a set distance H, where H is the diameter of the base 2-10 times of the value, the value is related to factors such as base series and pile height; e, use mechanical bottom expansion equipment or one of the positive and negative circulation methods to process the upper base space 3, take clean broken soil, and make the following pile body For the prefabricated hollow pile body, the crushed soil can be swept into the prefabricated pile body; f, the pouring concrete ...

Embodiment 2

[0024] As shown in Fig. 2, the steps a to g are the same as those in the embodiment 1. In the step h, the long steel bars 9 are put into the immersed tube 2, the upper base is poured with concrete, and the cast-in-place steel concrete is combined with the steel pipe to form the upper pile body and the pile.

Embodiment 3

[0026] Procedures a to h are the same as those in Example 1. In procedure i, insert short bars into the upper base and then pour concrete into the immersed tube 2 to form a composite upper pile body with cast-in-place concrete and steel pipes to form a pile. This method is suitable for use when the diameters of the upper and lower bases are large.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com