Underwater tunnel vertical jacking solid construction method and structure suitable for hard stratum

A technology for hard strata and underwater tunnels, applied to underwater structures, tunnels, water conservancy projects, etc., can solve the problems of increasing project duration, multi-project investment, and cost, and achieve reduced project cost, reduced project investment, and construction good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

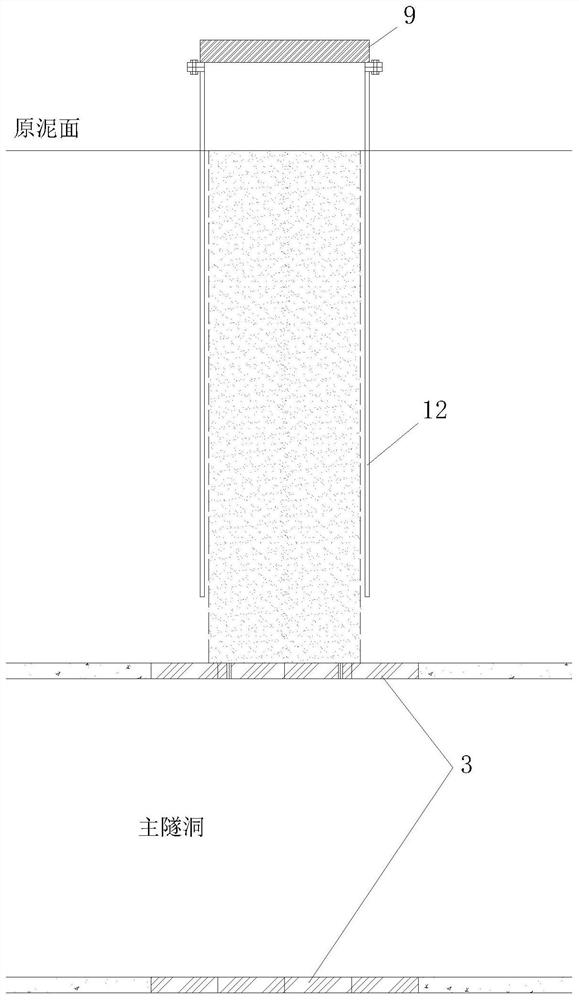

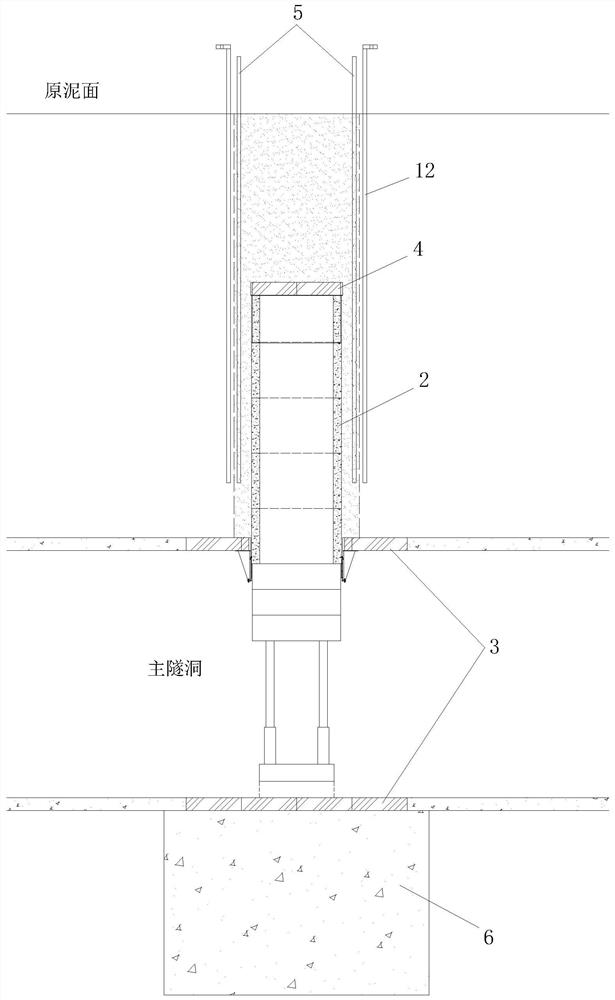

[0031] The present invention will be further described below in conjunction with accompanying drawing by specific embodiment:

[0032] The present embodiment carries out according to the following steps:

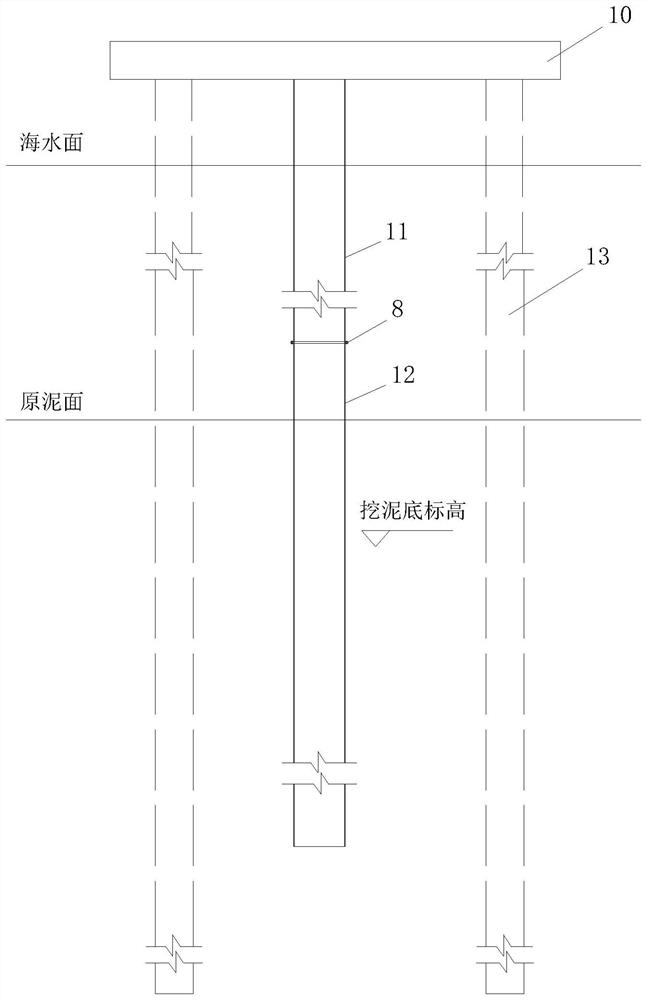

[0033] One, as attached figure 1 As shown, the construction platform 10 is set on the sea, and the steel casing is punched, and the specific steps are:

[0034] Step 1: Based on the design drawings and offshore measurement technology, accurately locate the position coordinates of each water outlet in the sea area, and build an offshore construction platform 10 near the drainage riser according to the design drawings. The bottom of the platform needs to be higher than the sea surface during the temporary construction period (considering the wave height) About 1m higher. The platform support 13 of the construction platform 10 needs to be drilled into a stable formation to ensure the stability of the construction platform 10 during the drilling replacement.

[0035]The secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com