Rice field land shaper

A technology for building ridge machines and paddy fields, which is applied in the fields of tillage machines, agricultural machines and machines, etc. It can solve the problems of high labor intensity, long operation cycle, and low efficiency, so as to avoid duplication of labor, shorten operation cycle, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

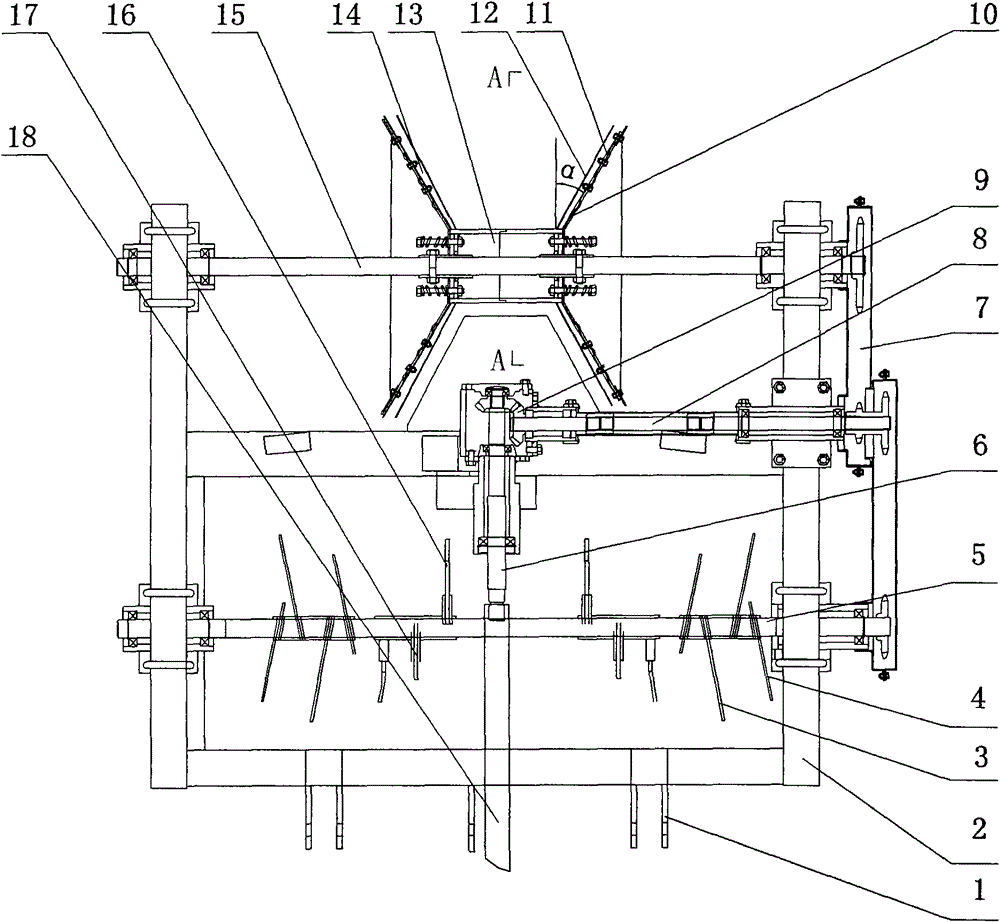

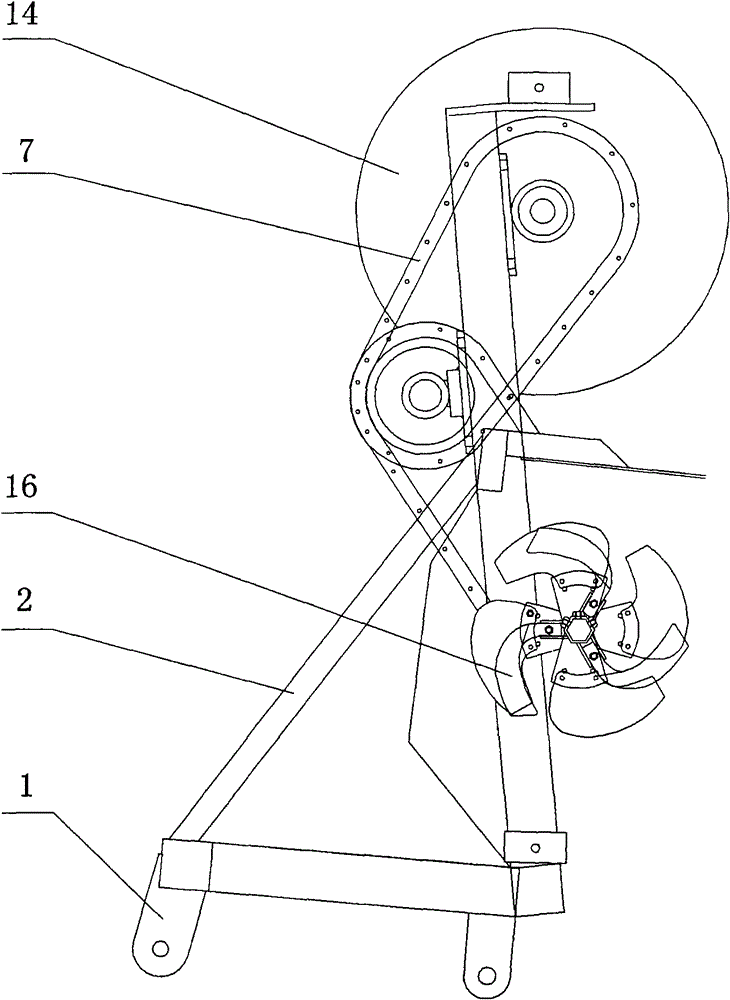

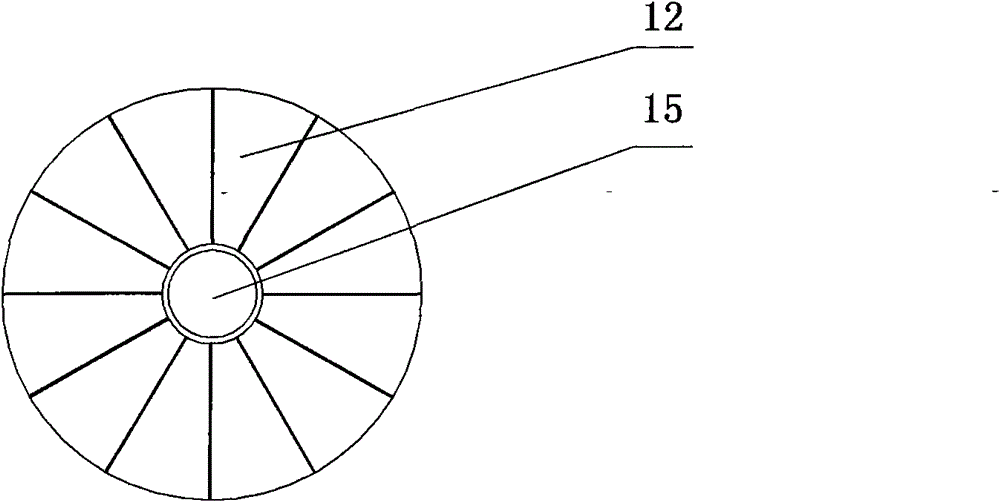

[0016] The present invention comprises frame 2, and the front of frame 2 is provided with hanger 1, and the gear box 9 that has input shaft 6, output shaft 8 is arranged on frame 2, and output shaft 8 is connected with the front with reamer 16 respectively through chain 7. Axle 5, the rear axle 15 that has ridge cutter 14 is connected; Described ridge cutter 14 is made of the wheel hub 10 that the center is that axle sleeve 13 and both sides are symmetrically provided with outwardly inclined conical surface 11, and conical surface 11 is fixed with unidirectional Inclined elastic pressure piece 12.

[0017] Blades 3 are respectively arranged on the outside of the reamer 16, which is more conducive to the concentration and accumulation of the soil layer in the middle, and is conducive to the operation of the ridge cutter 14.

[0018] The reamer 16 can be composed of three uniformly distributed reamer bodies 17, and the blade 3 is composed of four uniformly distributed blade bodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com