Stranded cable wedge

a technology of stranded cables and wedges, which is applied in the direction of cables, mechanical equipment, ropes and cables for vehicles/pulleys, etc., can solve the problems of reducing the anchoring performance of the rope placement tool, affecting the anchoring performance of the rope, so as to prevent the above-mentioned nipping damage and prevent the damage of the stranded cabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

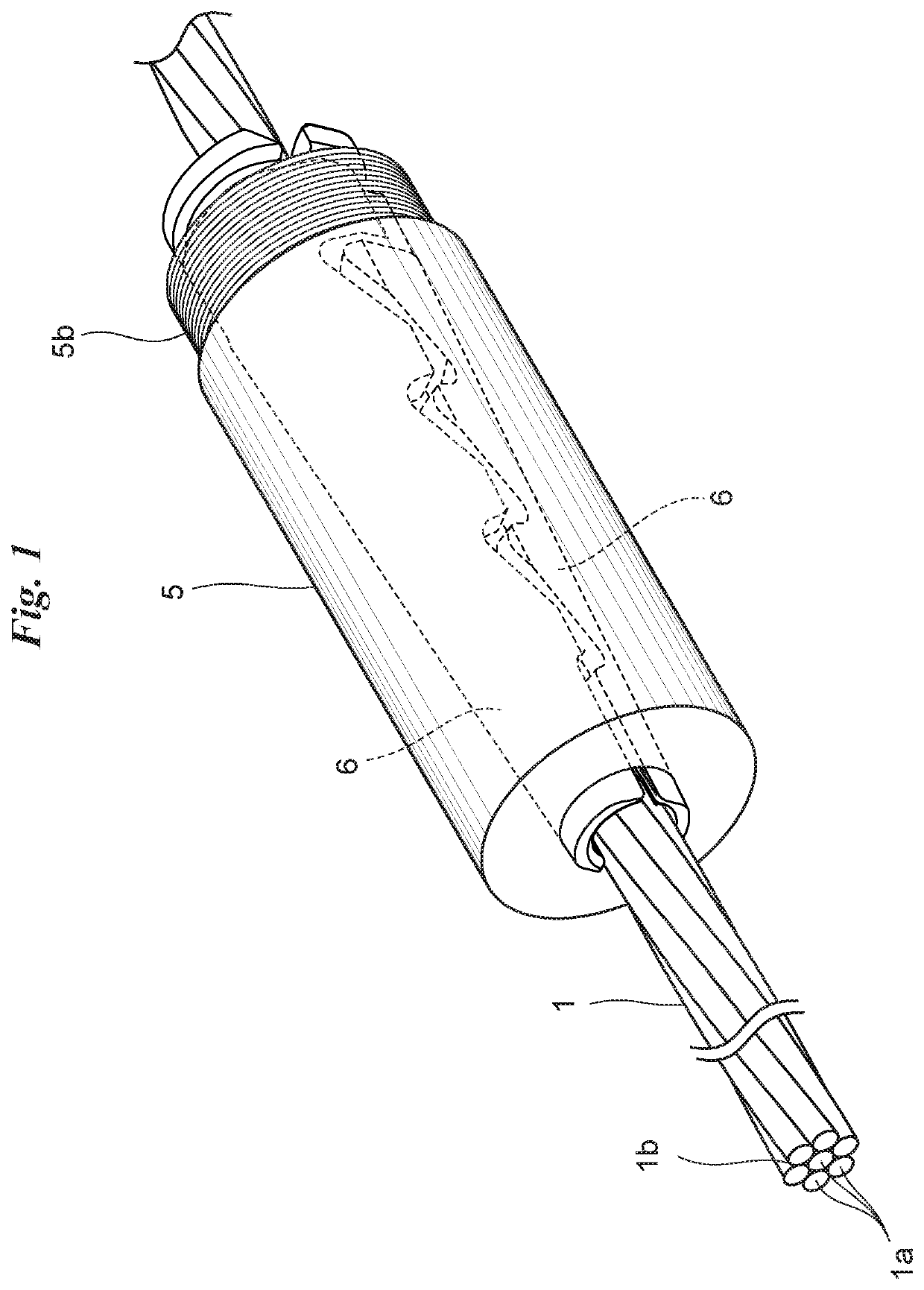

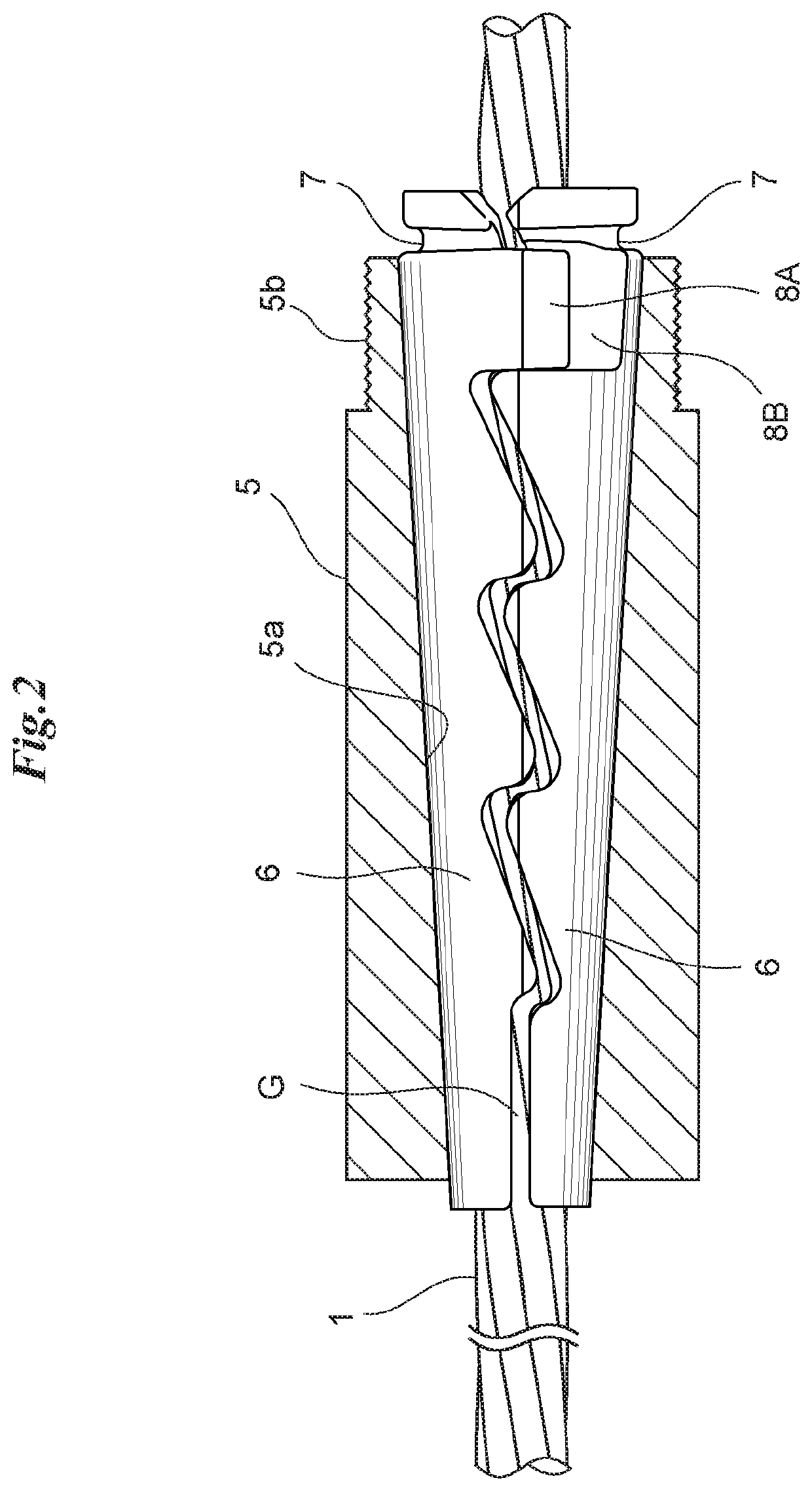

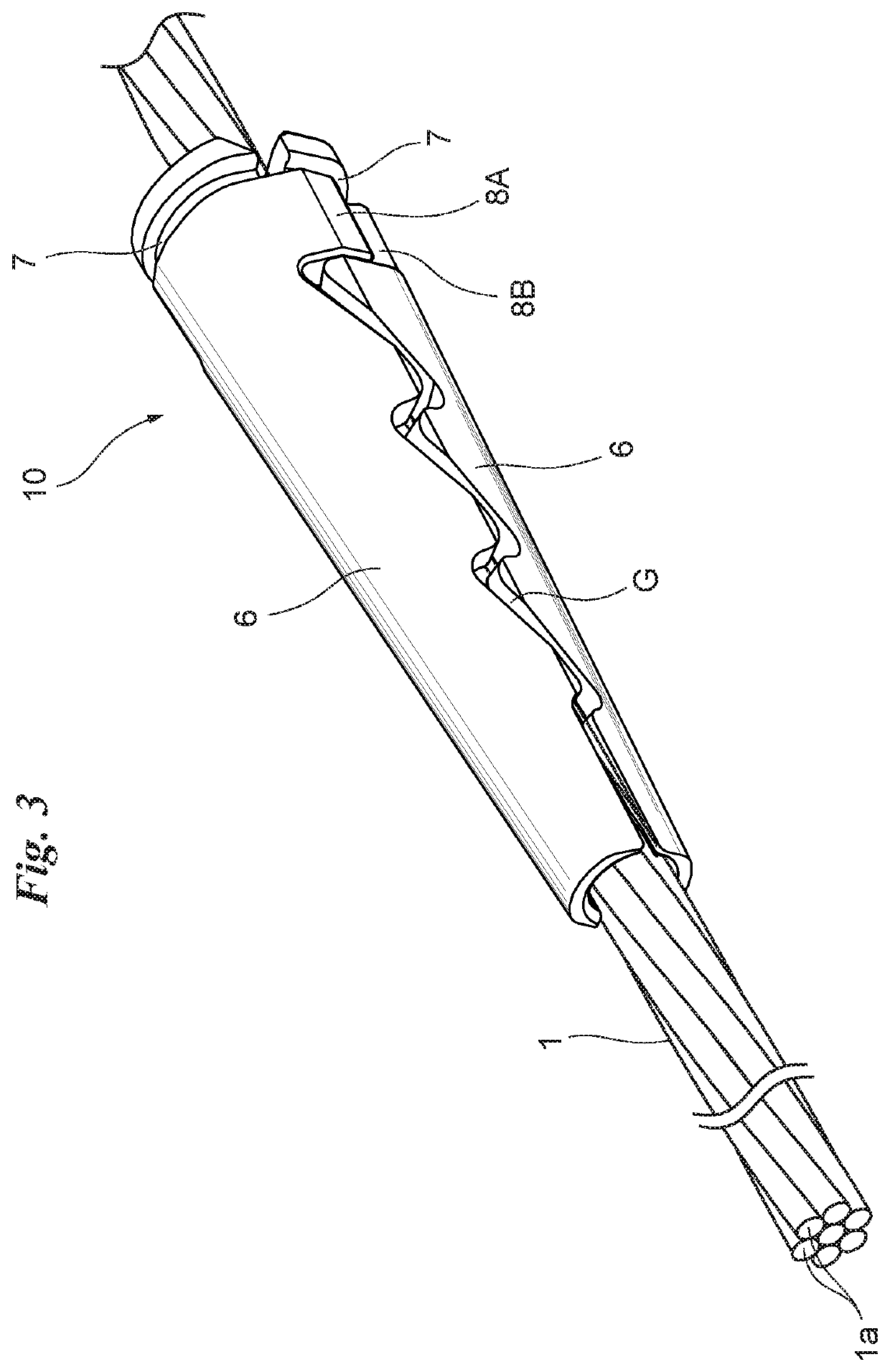

[0035]FIG. 1 is a perspective view illustrating an embodiment in which a terminal anchoring structure is applied to a terminal end portion of a cable 1 made of carbon fiber reinforced plastic (CFRP) (referred to also as a Carbon Fiber Composite Cable) (referred to as a CFRP cable below). FIG. 2 is a longitudinal sectional view of the terminal anchoring structure. FIG. 3 is a perspective view illustrating the manner in which two split wedge bodies have been attached to a terminal end portion of the CFRP cable 1, and FIG. 4 is an exploded perspective view thereof. FIG. 5 is a side view when two split wedge bodies have been attached to a terminal end portion of the CFRP cable 1. FIGS. 6 to 8 are enlarged sectional views taken along lines VI-VI, VII-VII, VIII-VIII of FIG. 5, respectively.

[0036]With reference to FIGS. 1 and 6, the CFRP cable 1 has a 1×7 structure obtained by twisting together seven carbon fiber bundles 1a, which are made of carbon fiber reinforced plastic and have a circ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com