Methods and Designs for Balancing a Stranded Termination Assembly

a technology of stranded termination and assembly, applied in the field of methods, can solve the problems of difficult organization, more complicated end fittings, and difficult handling of synthetic filaments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0120]FIG. 4 shows an exemplary device used to gather all the strands into a unified whole and thereby create an overall cable termination. Collector 34 includes twelve receivers 38, each of which is configured to connect to a single strand termination (In other embodiments a receiver may be configured to connect to multiple strand terminations). Collector 34 typically includes some type of load-transferring feature designed to transfer a load from the collector to some external element. Loading flange 36 is a simple example of a load-transferring feature. The collector in this example is very simplistic and is unlikely to represent a design that would actually be used. However, it does serve well to clearly illustrate the inventive features.

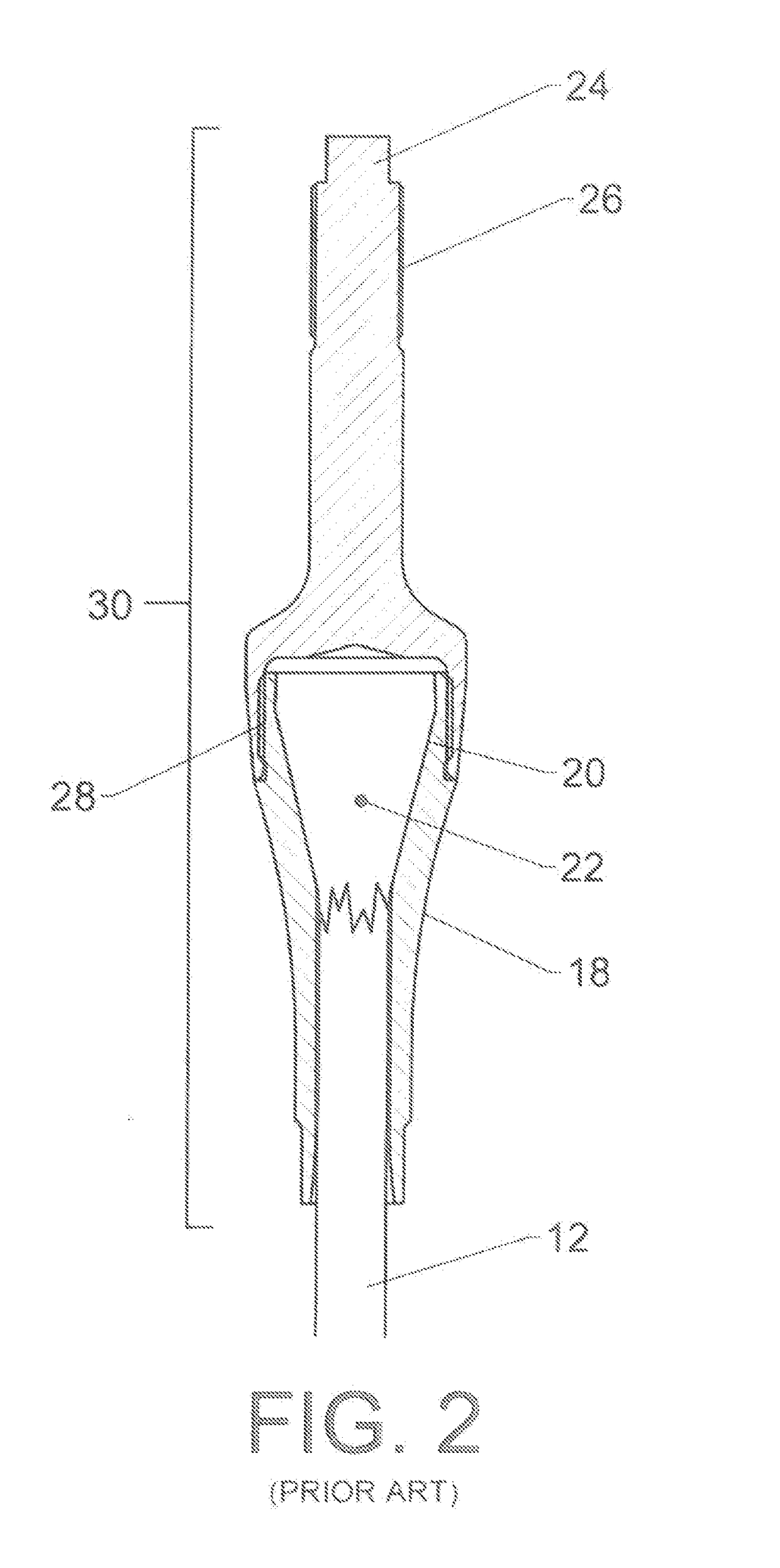

[0121]FIG. 5 shows an exemplary connection between a termination on a strand and the collector. Loading stud 24 is passed through opening 46 and through receiver 38 in collector 34. Receiver 38 includes a hemispherical concave portion sized to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com