Metal rope helmet machining process and matching die

A processing technology, metal rope technology, used in the bundling of ends, textiles and papermaking, textile cables, etc., can solve the problems of textile or human injury, uneven pressure, damage to the protective coating on the outer surface, etc., to achieve the overall shape Intact, reduced production costs, sleek and full appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

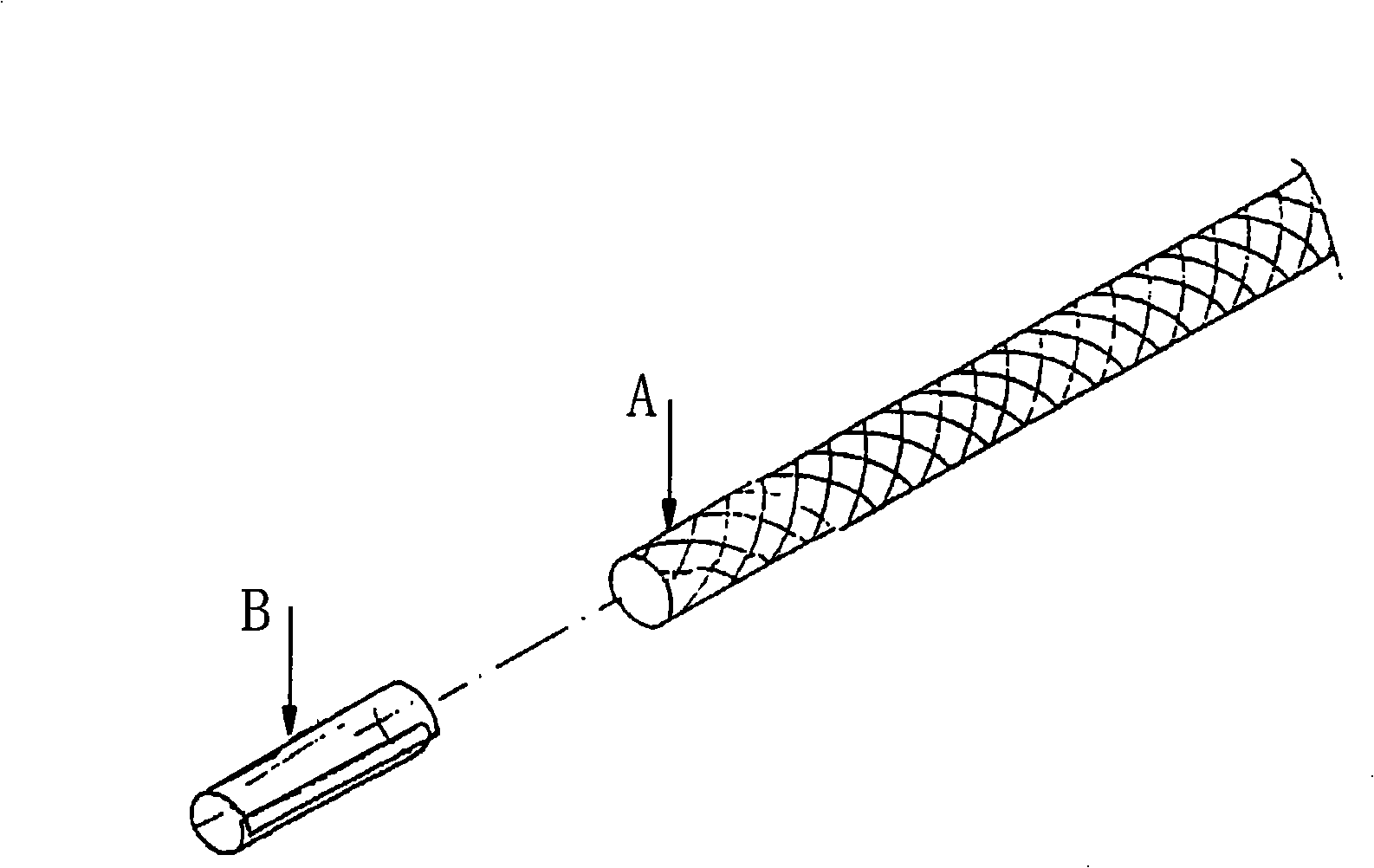

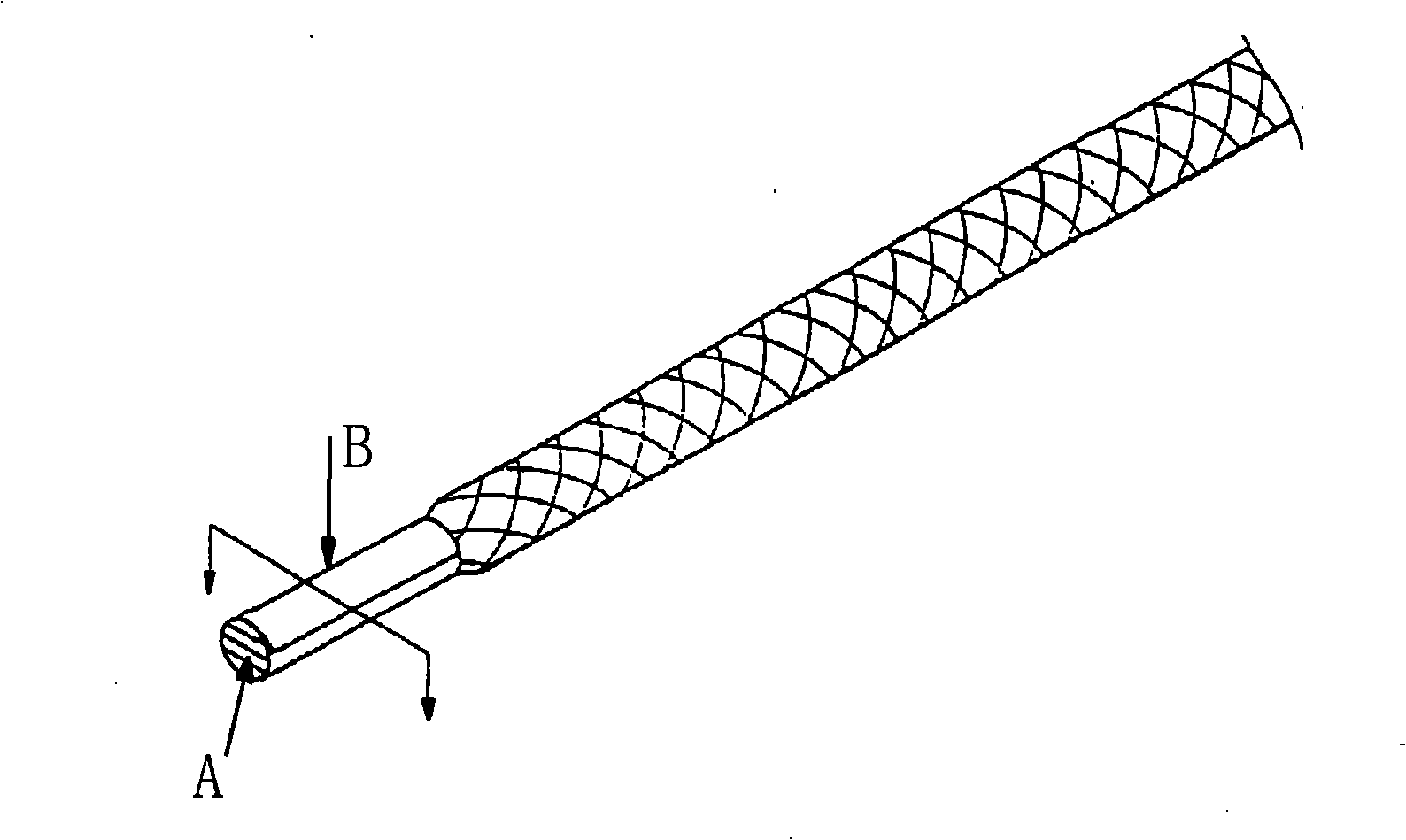

[0052] see Figure 9 , the metal rope headgear processing technology includes the following steps:

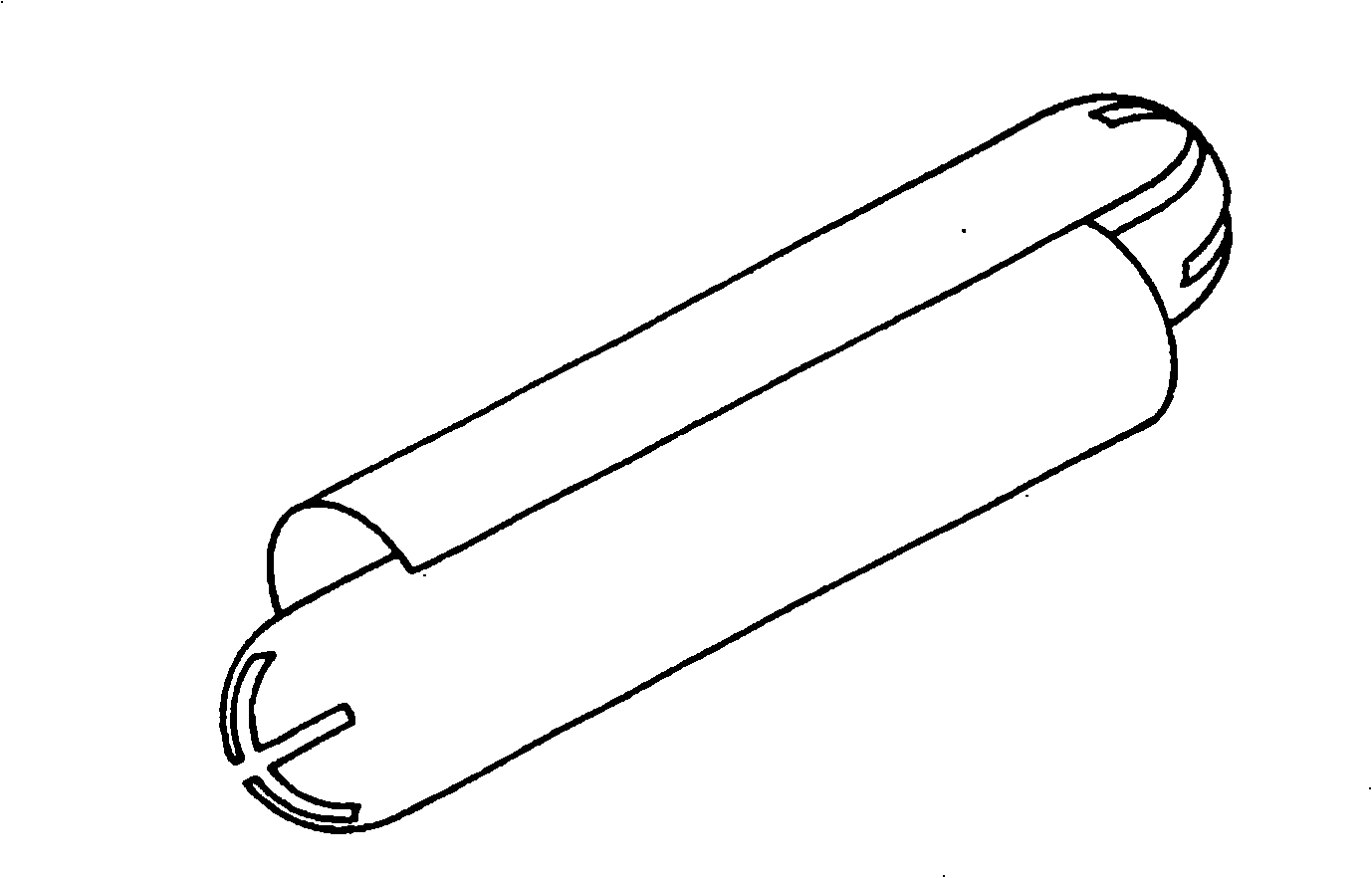

[0053] 1. Using conventional technology, use copper to process a metal headgear 1, so as to pass through the sensitive needle detector. See Figure 6, Figure 7 and Figure 8 The shape of the metal headgear 1 is cylindrical, with a hemispherical 11 at one end and a circular opening 12 at the other end. There is a trident suture 13 at the hemispherical 11, and a side suture 14 at the side edge. The sutures 14 are connected and communicated with both ends of the metal headgear 1; of course, the metal headgear 1 can also be in other shapes, such as a cylindrical shape. What kind of conventional process is used is well known to those skilled in the art, and will not be described in detail here.

[0054] 2. Process the film-type rope head 3 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com