Device for producing jointless steel cable loop

A technology for manufacturing equipment and steel wire ropes, which is applied in the field of manufacturing equipment for non-joint steel wire rope loops, can solve the problems of high labor intensity, low production efficiency, and difficulty in ensuring product quality, so as to reduce labor intensity and improve production efficiency and product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

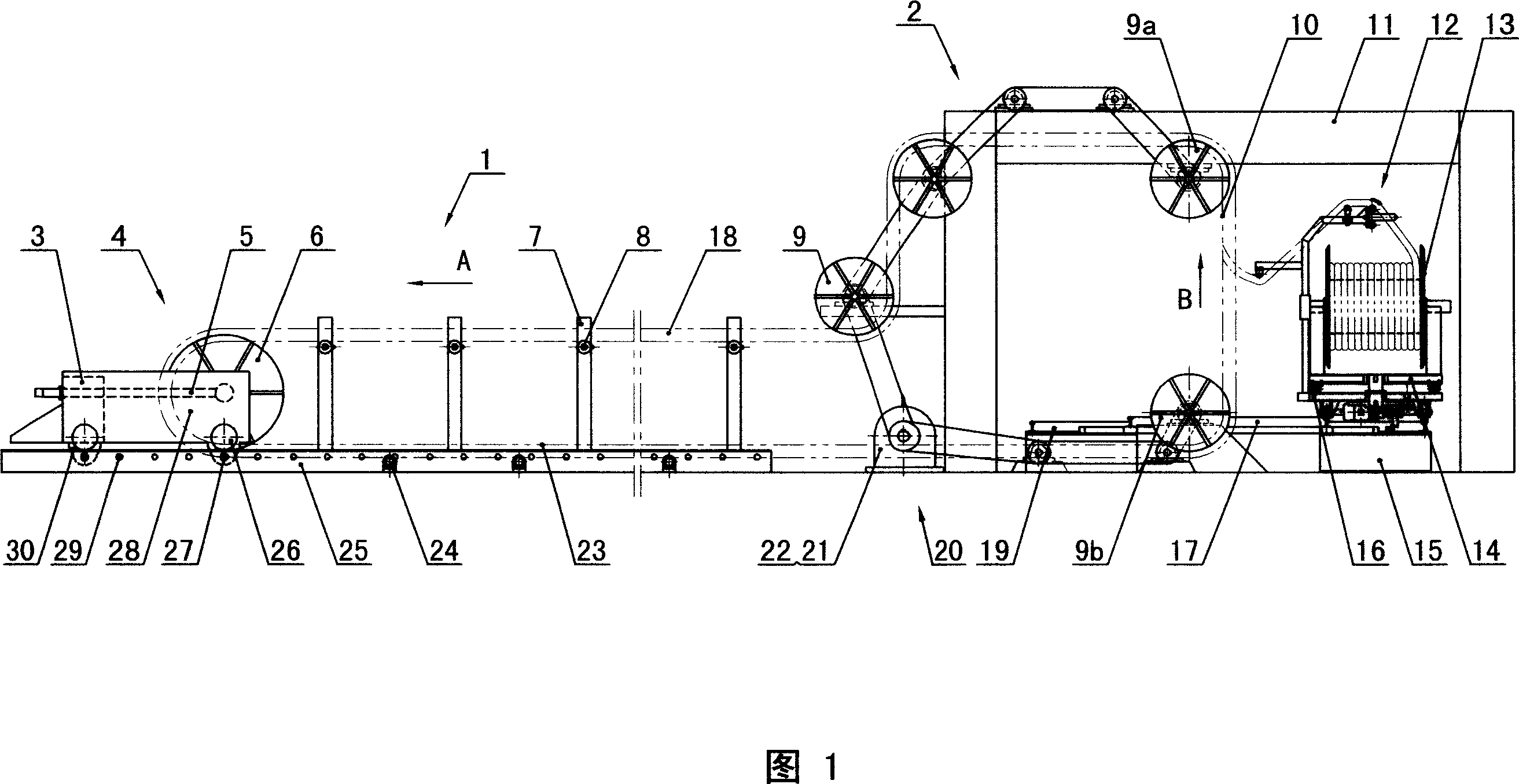

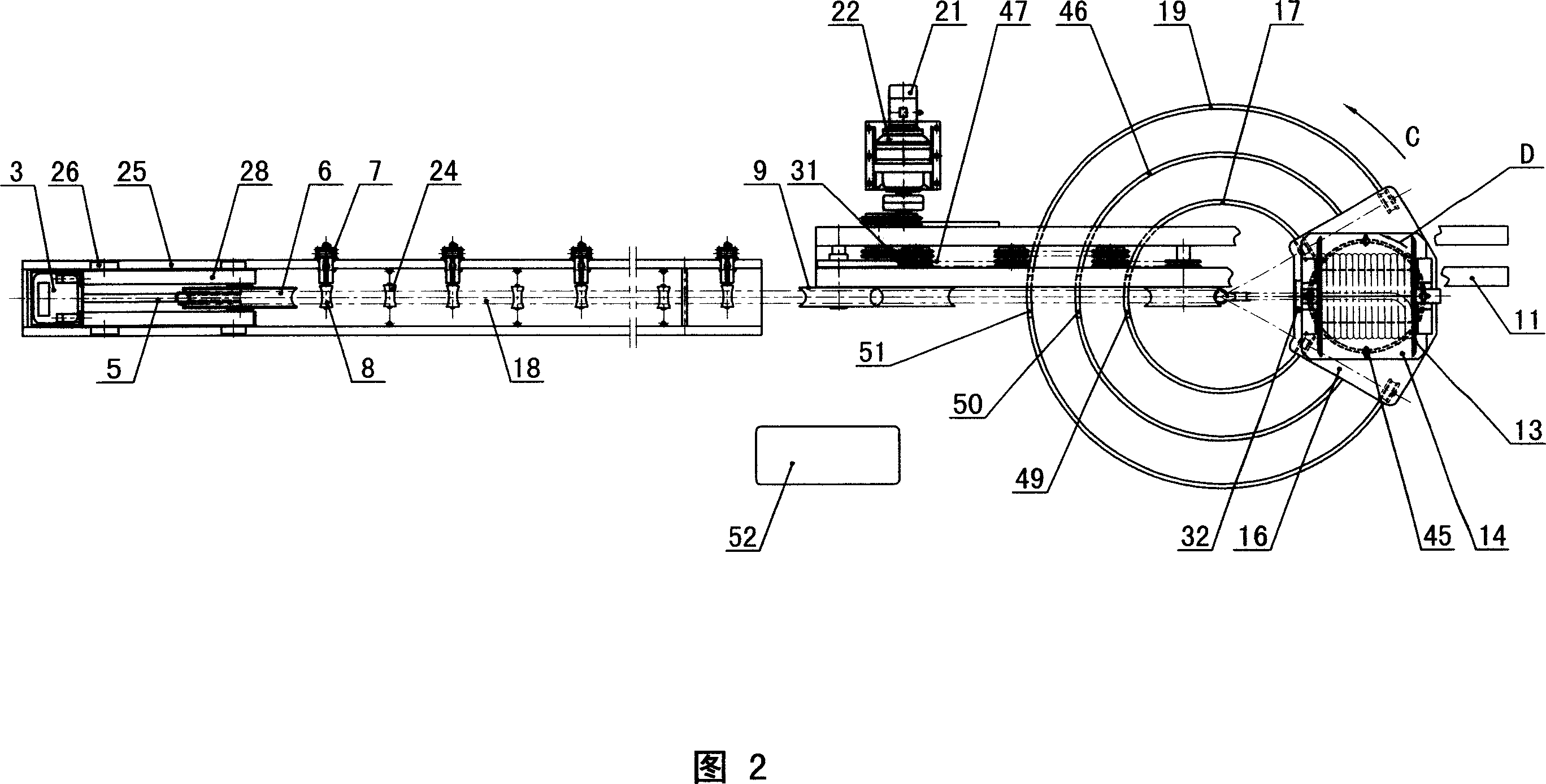

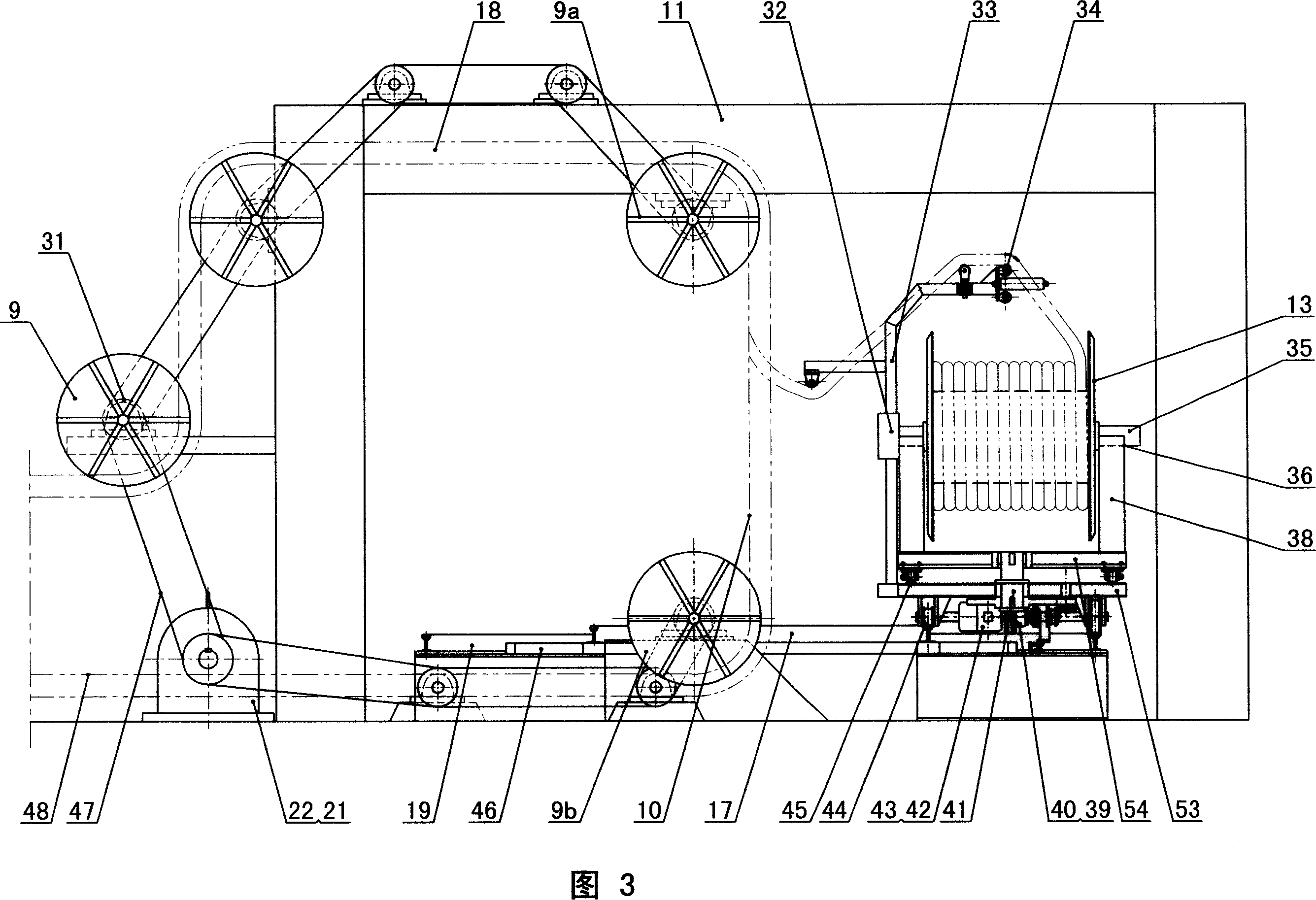

[0018] Referring to Fig. 1, Fig. 2 and Fig. 3, the embodiment of the manufacturing equipment of the endless steel wire rope loop of the present invention includes a core rope transmission system and a sub-rope winding system.

[0019] The core rope transmission system includes a tensioning device 1 and a driving device 2 .

[0020] The tensioning device 1 includes two linear guide rails 25 parallel to each other installed on the ground and the tension wheel assembly 4 installed on the linear guide rails 25 . The idler assembly 4 includes an idler bracket 28, an idler 6 mounted on the idler bracket 28 and whose axis is perpendicular to the linear guide rail 25, an idler positioning device installed on the idler bracket 28 and a hydraulic pressure station 3. Two pairs of linear rollers 26 are symmetrically installed on both sides of the bottom of the tensioning wheel support 28, and the linear rollers 26 are respectively located on two linear guide rails 25 and can roll thereon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com