Hot cutting machine for cutting automobile wire harness braided wire

A technology of thermal cutting machine and automobile wiring harness, which is applied in the cutting of textile materials, the bundling of textile cables and ends, etc., can solve the problems of low cutting efficiency, influence of wiring harness, loose and messy braided wires, etc., and reduce the investment of human resources. , Improve work efficiency and reduce the effect of other processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

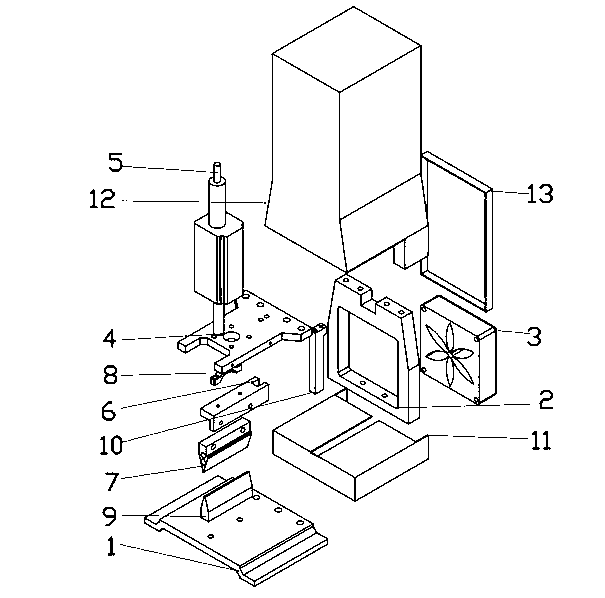

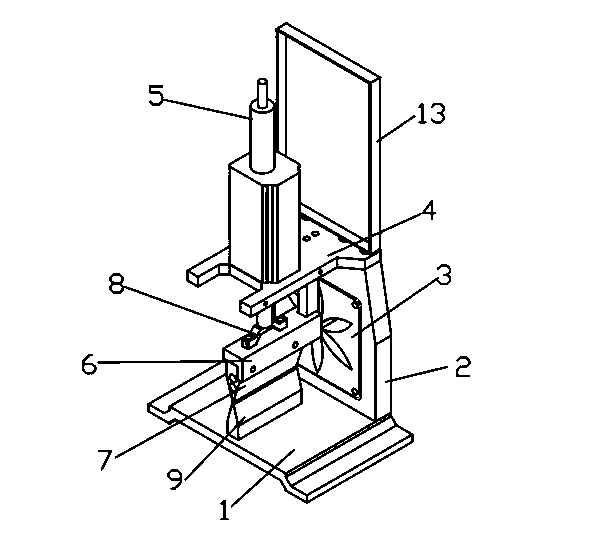

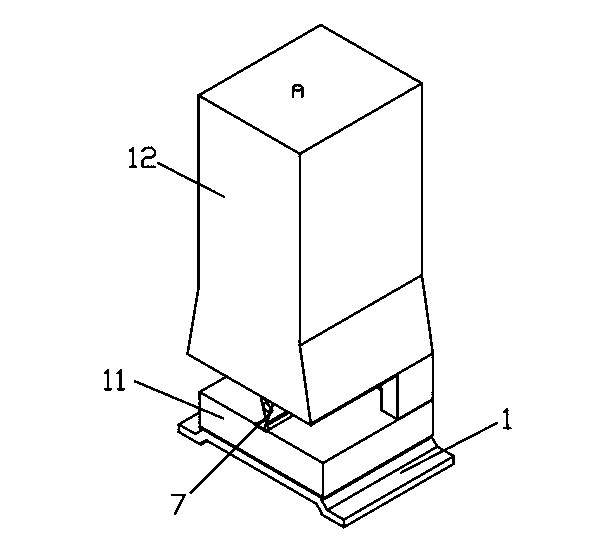

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] In this embodiment, refer to Figure 1~3 , a thermal cutting machine for cutting braided wires of automobile wiring harnesses, comprising a horizontally placed base plate 1 and a vertical plate 2 standing on one side of the base plate 1, the surface of the base plate 1 is fixedly provided with a fixed lower knife 9 with the blade pointing upward , the top of the vertical plate 2 is horizontally fixed with a cylinder fixed plate 4, and the top of the cylinder fixed plate 4 is vertically provided with an adjustable cylinder 5 penetrating into the cylinder fixed plate 4, and the piston rod at the front end of the adjustable cylinder 5 is fixedly connected with a fixed bracket 8 , and fixedly connected with a knife seat 6 at the lower end of the fixed bracket 8, the knife seat 6 is equipped with a movable upper knife 7 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com