Intelligent extruding stay rope based on filled type epoxy coating steel strand and manufacturing method

A technology of epoxy coating and steel strand, which is applied in the direction of end bundling, bridges, manipulation parts, etc., which can solve the problems of difficult operation, difficult notching, and difficult quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

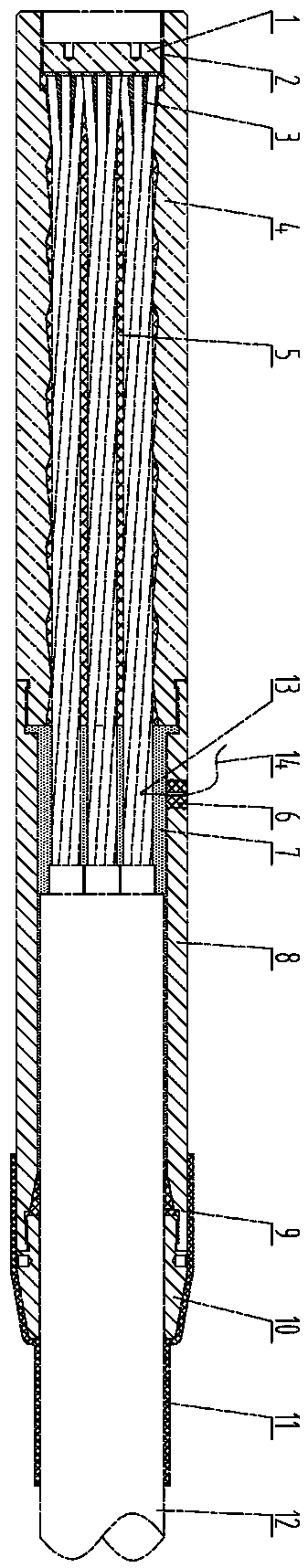

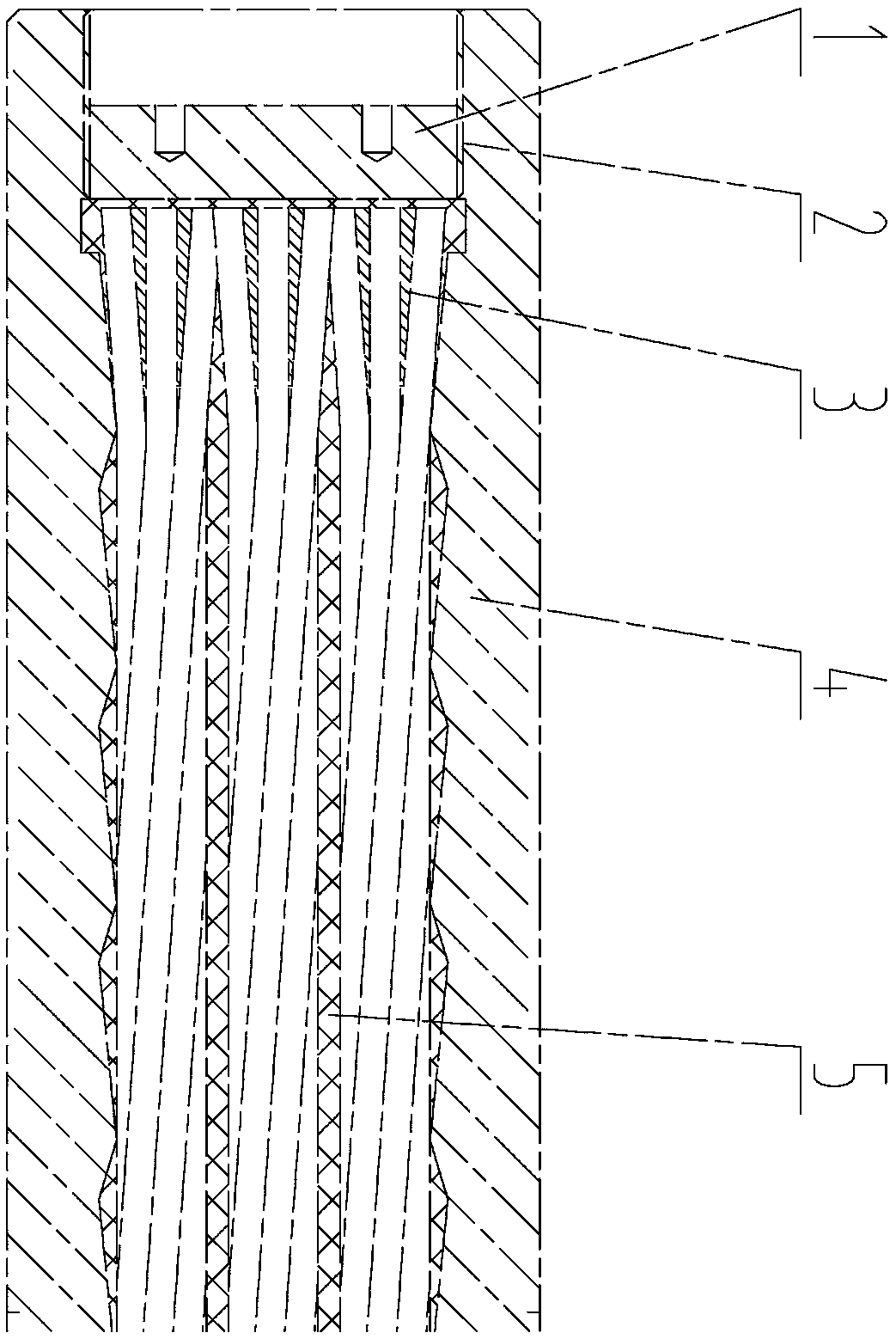

[0036] In the figure, 1-end sealing cover, 2-raw material belt, 3-small taper sleeve, 4-anchor sleeve, 5-epoxy iron sand, 6-threaded hole, 7-liquid sleeve anti-corrosion oil, 8-seal cylinder, 9-Sealing ring, 10-Transition sleeve, 11-Heat shrink sleeve, 12-Cable body, 13-Optical fiber and fiber Bragg grating sensor, 14-Optical fiber and fiber Bragg grating sensor lead.

[0037] like figure 1As shown, the intelligent extruded cable based on filled epoxy-coated steel strands includes cable body, tension end anchor, fixed end anchor, epoxy iron sand, liquid anti-corrosion oil, optical fiber and fiber grating sensor. Among them, both the tension end anchor and the fixed end anchor include: end sealing cover, small cone sleeve, anchor sleeve, sealing cylinder, sealing ring, transition sleeve, heat shrinkable sleeve; among them, the distance between the sealing cylinder and its lower end is 1 / 3 M18 threaded hole 6 is set at the place to facilitate the extraction of optical fiber and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com