Technique for pouring hoisting cable anchorage head with alloy

A technology of steel wire rope and anchoring head, applied in the field of steel wire rope, can solve the problems of high asking price and inability to meet technical requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

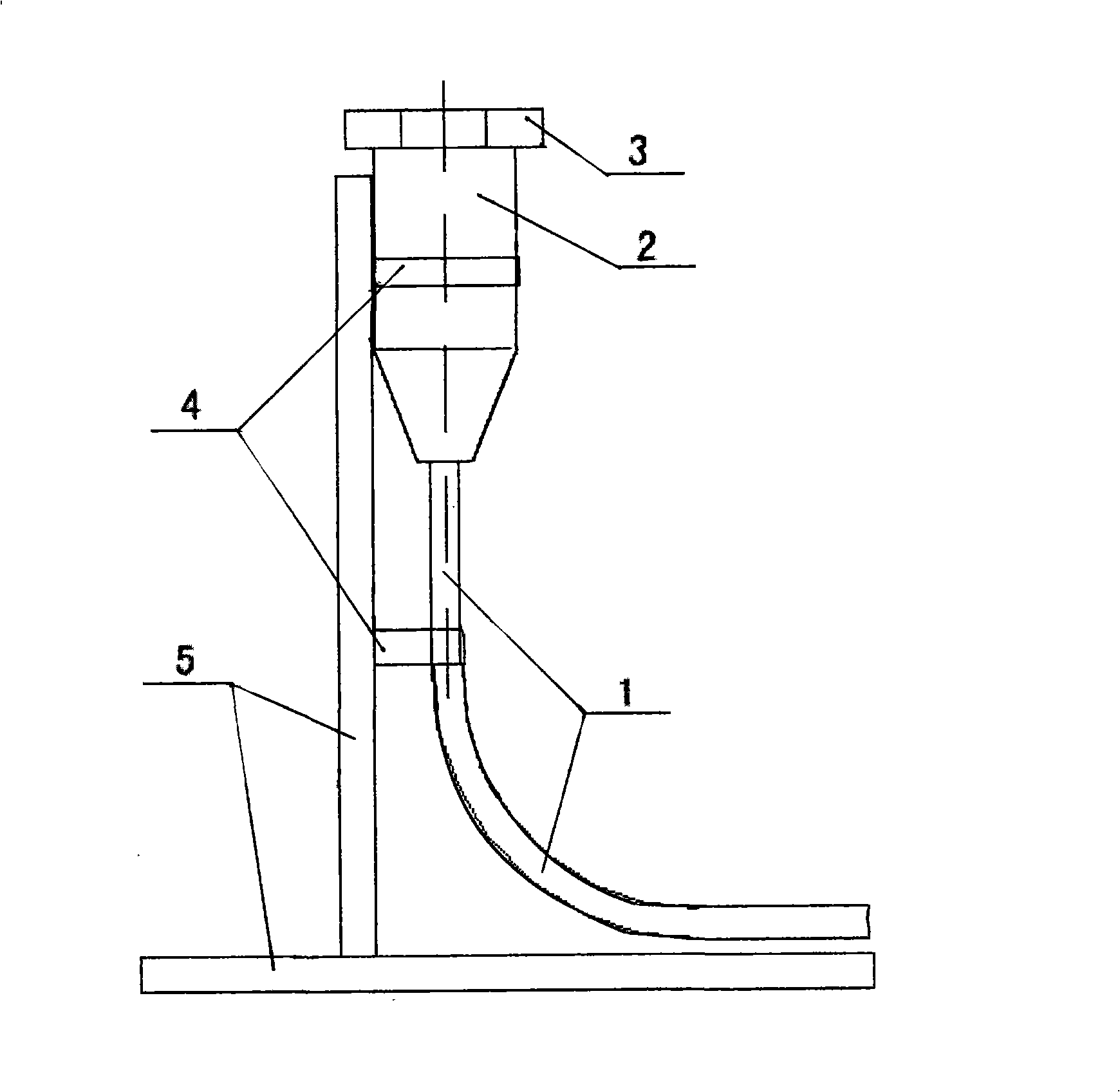

[0081] In the construction of the Jiuhuashan and Lushan cableways undertaken by our company, we successfully carried out the alloy casting of 24 traction and balance cables, 4 tension cables, and 8 rope ends for bearing cables.

[0082] Among them, during the tension cable construction of the Yungu cableway in Huangshan Mountain, the foreign party provided four Φ52mm imported steel wire ropes, one end of which had already been anchored. The anchor head needs 60,000 yuan, and the four pieces need 240,000 yuan. In order to reduce the cost for the owner, we made four anchor heads according to the above method, and the total cost is only 32,000 yuan. Only this item saves the owner 218,000 yuan. ;After ten years of operation, when the tensioning cable was replaced, the casing was opened for inspection. Compared with the external anchor head, there was no loosening phenomenon. When replacing the new cable in 2001, Party A entrusted us to make all the anchor heads.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com