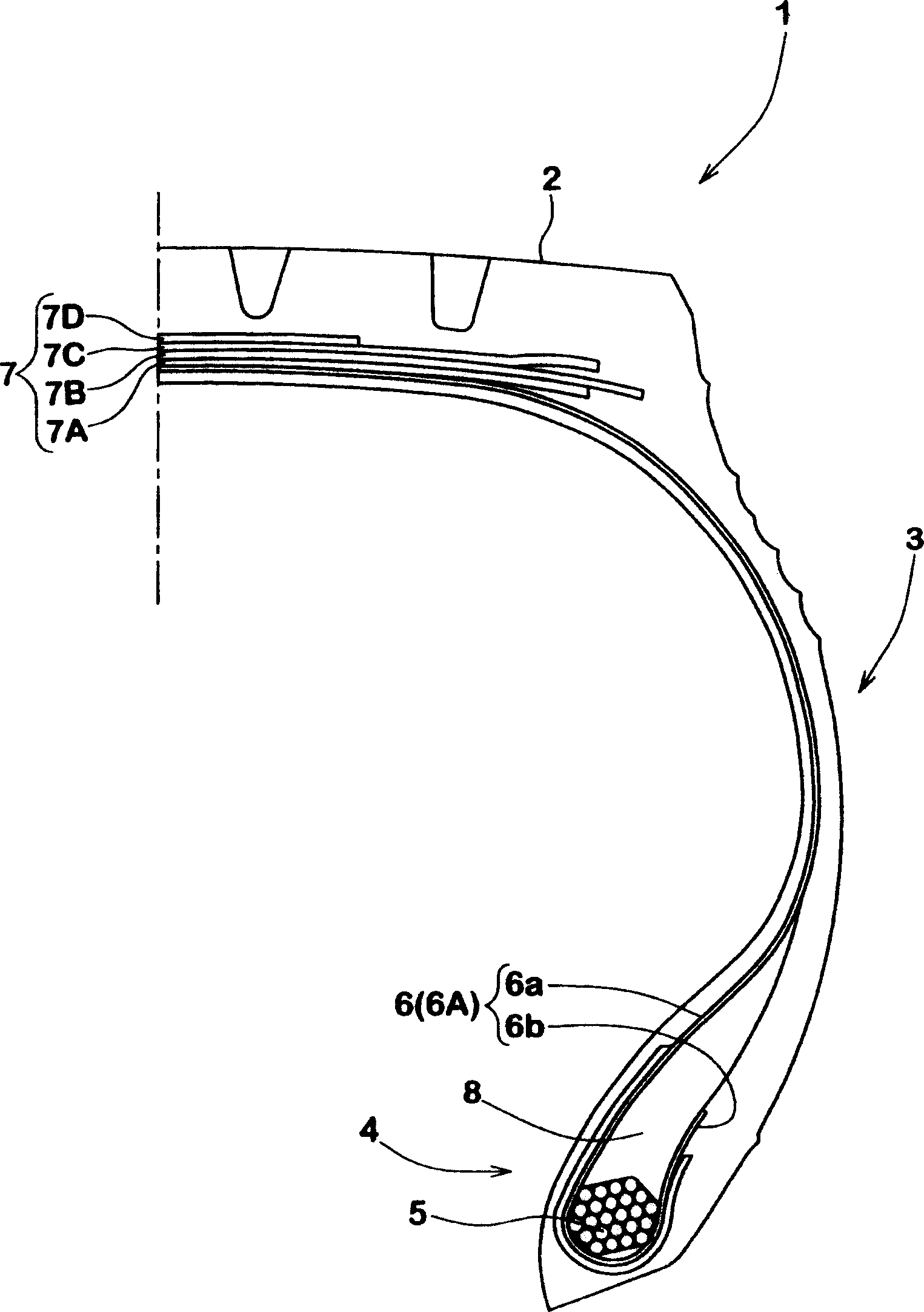

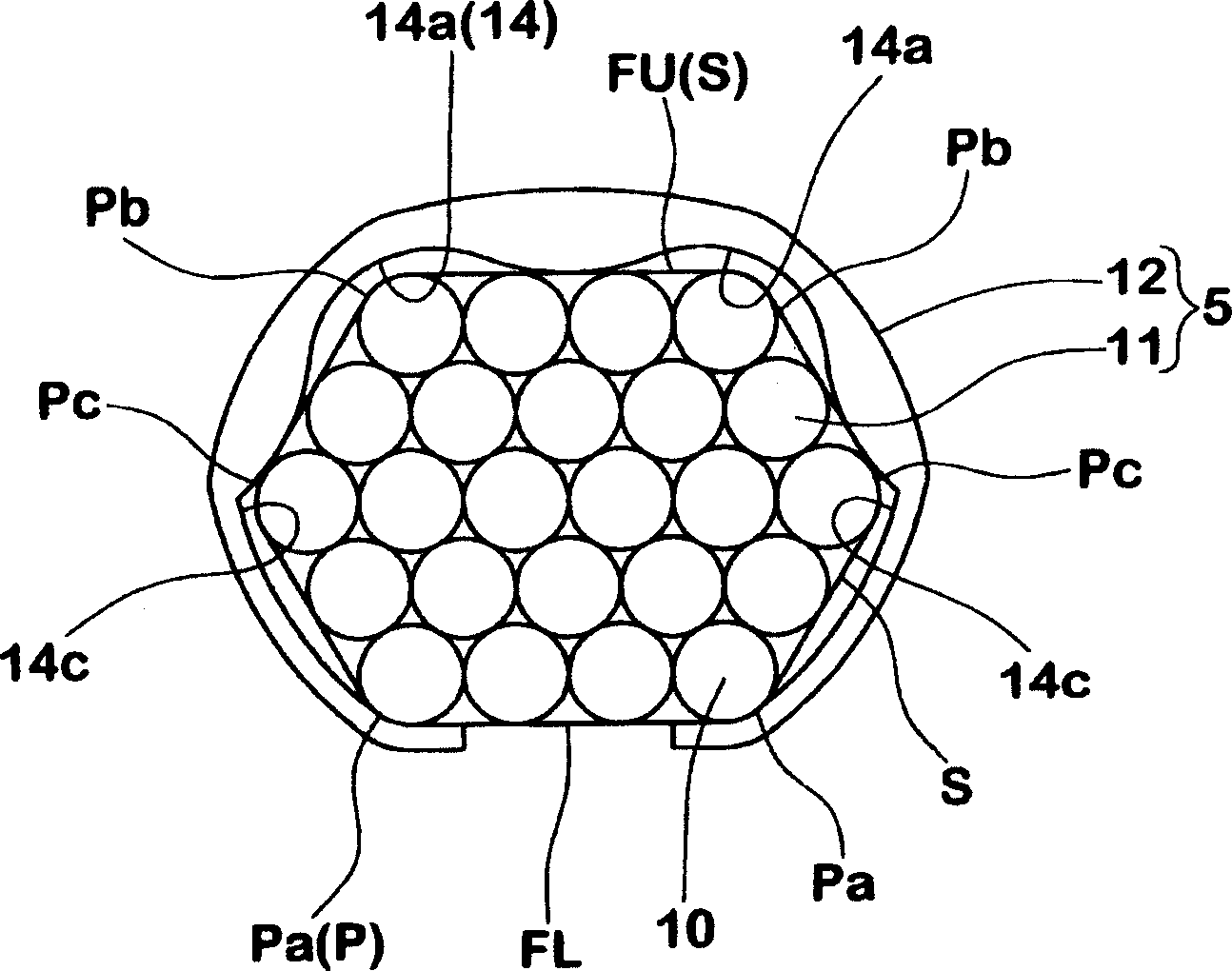

Bead core of pneumatic tire

A technology for pneumatic tires and bead cores, which is applied to tire parts, tires, tire edges, etc., and can solve problems such as damage to the inner liner rubber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

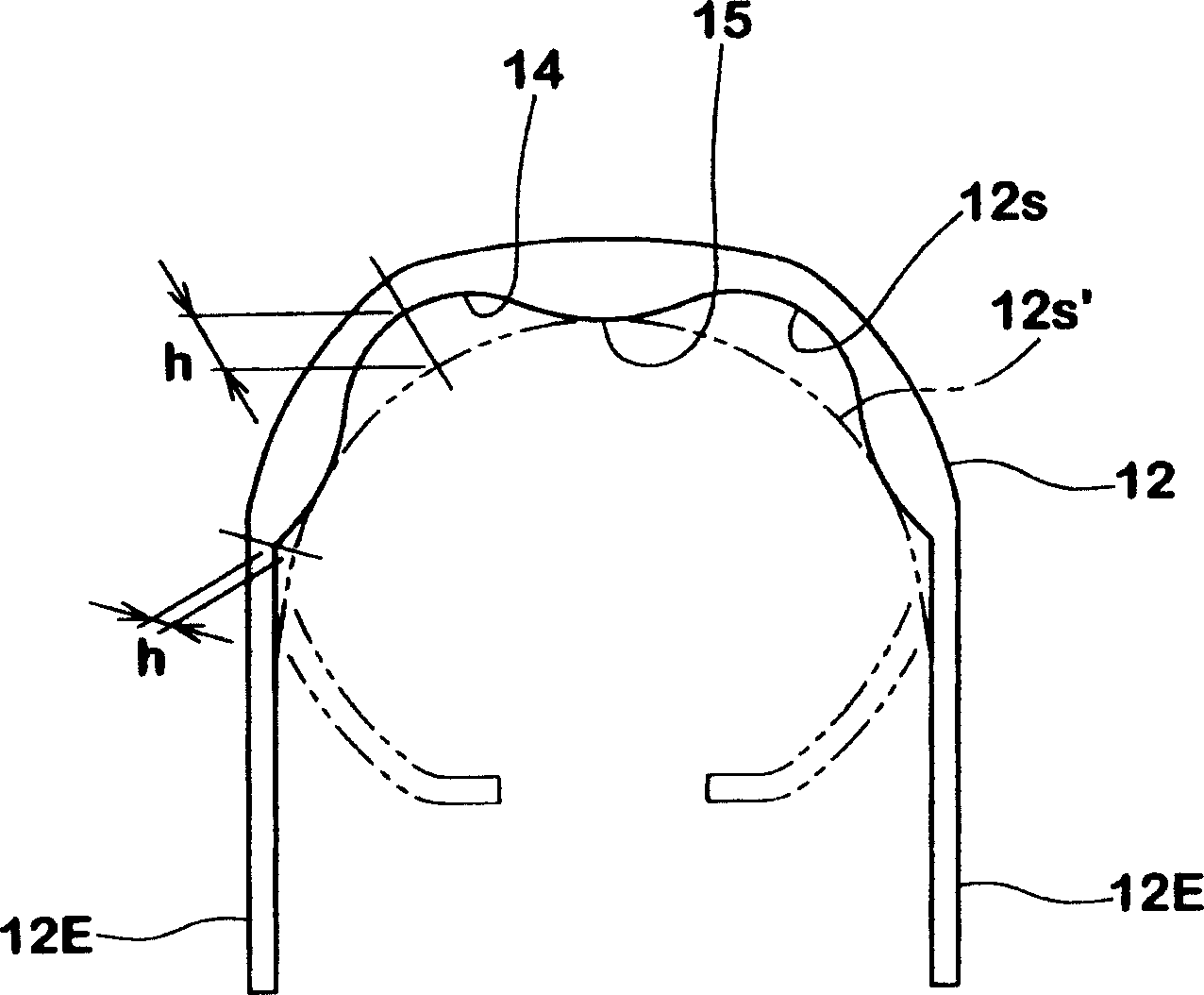

[0045] The staple device 12 was manufactured with various changes in the number (m) and height (h) of the concave portion 14 formed, and it was used for a bead body having a horizontally long and flat hexagonal truncation 11( image 3 ). The bead core 5 with the bead wire 10 fixed by the staple device 12 was used to prepare 1000 green tires by the ordinary method. It is detected whether the tip portion of the staple device 12 is exposed to the inner cavity of the tire when the rotational displacement occurs. The incidence rate (%) of exposure is shown in the appendix Figure 7 .

[0046] As described above, when the number (m) of concave portions of the staple device is 2 or 3, when the height (h) is set within the range of 0.5 to 1.3 mm, the incidence of exposure can be limited to 0%. Furthermore, when the number (m) of concave portions of the staple device is 4, when the height (h) is set within the range of 0.4 to 0.8 mm, the incidence of exposure can be limited to 0%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com